A device for testing the anti-loosening performance of threaded fasteners

A technology for threaded fasteners and test devices, which is used in measuring devices, vibration testing, and testing of machine/structural components, etc., can solve problems such as unreasonable steel plate connection structure, troublesome adjustment, mechanical structure damage, etc., to ensure horizontal movement. Stability, guaranteed speed and precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to better understand the present invention, the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

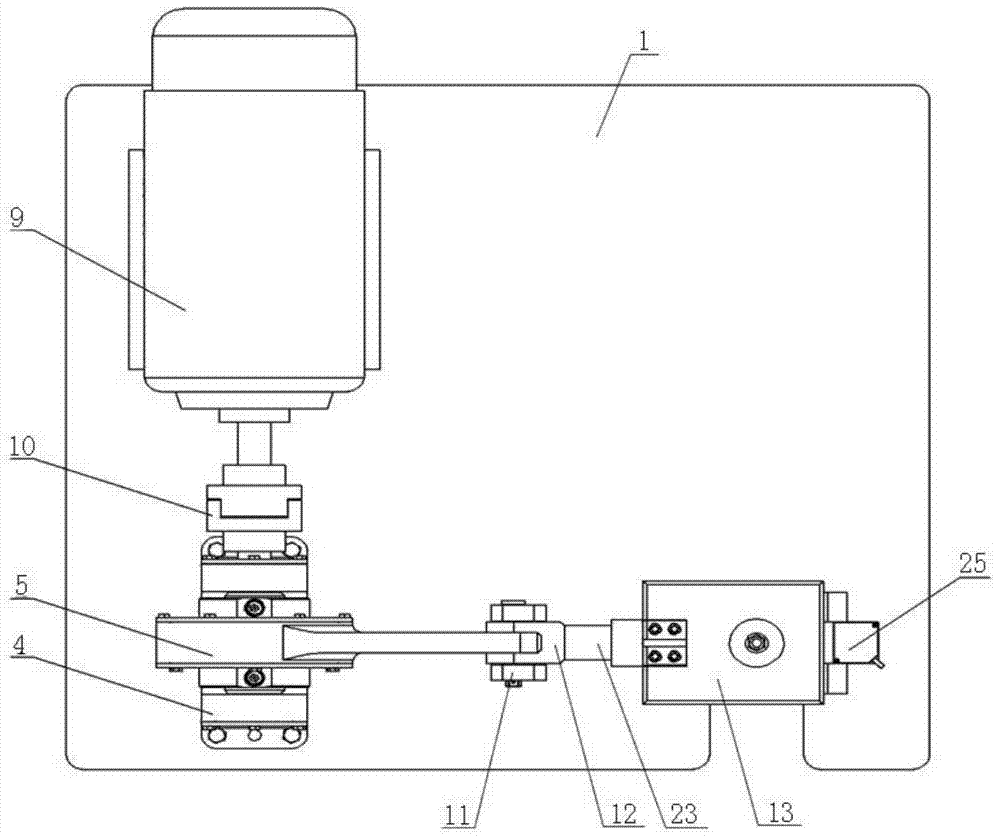

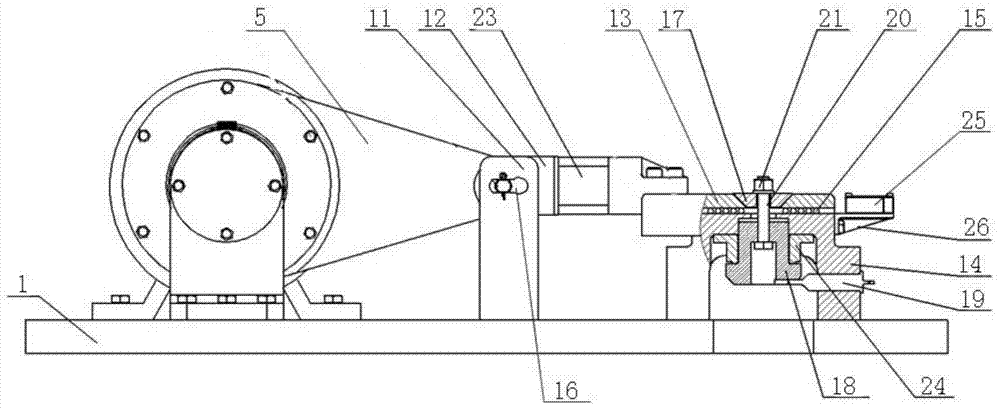

[0024] like figure 1 As shown, a test device for testing the anti-loosening performance of threaded fasteners includes a base 1, a power system, an amplitude adjustment system, a lateral vibration system, and a sensing system. The power system, the amplitude adjustment system, and the lateral vibration system are all fixed On the base 1, the power system, the amplitude adjustment system, and the lateral vibration system are sequentially connected, and the sensor system is connected with the lateral vibration system.

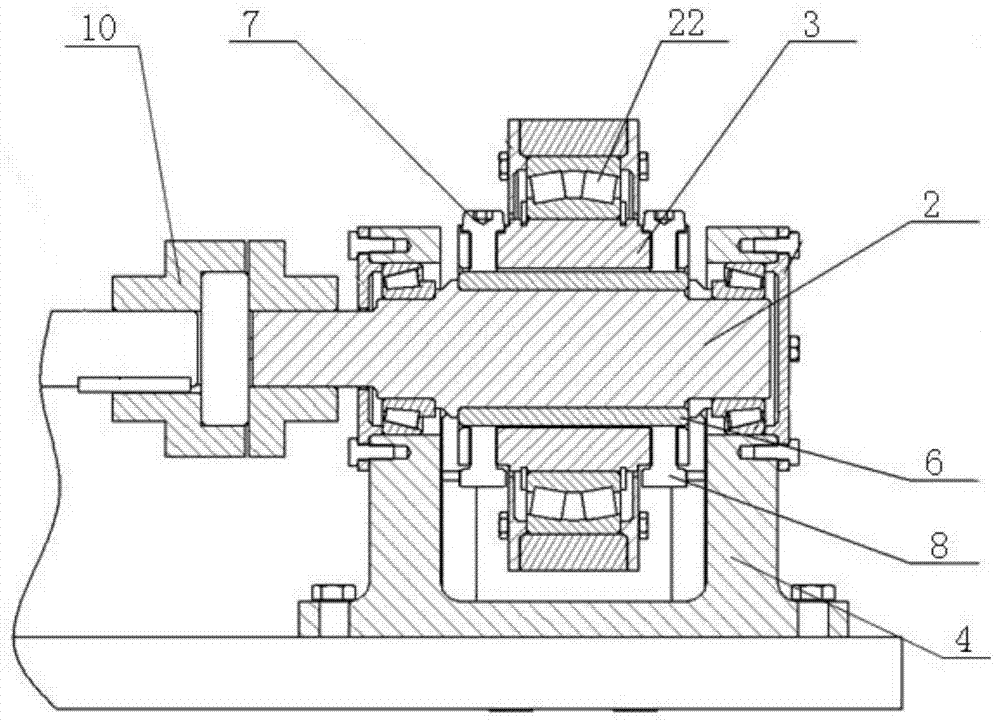

[0025] like Figure 1-3 As shown, the power system is a variable frequency motor 9 , and the output shaft of the variable frequency motor 9 is connected to one end of the transmission shaft 2 of the amplitude adjustment system through a coupling 10 .

[0026] like image 3 As shown, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com