Low-temperature acid dew point corrosion experimental device for power station boiler flue gas

A technology for corrosion experiments and power plant boilers, applied in weather resistance/light resistance/corrosion resistance, measuring devices, instruments, etc., can solve problems such as high cost, difficult processing, and affecting heat transfer performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

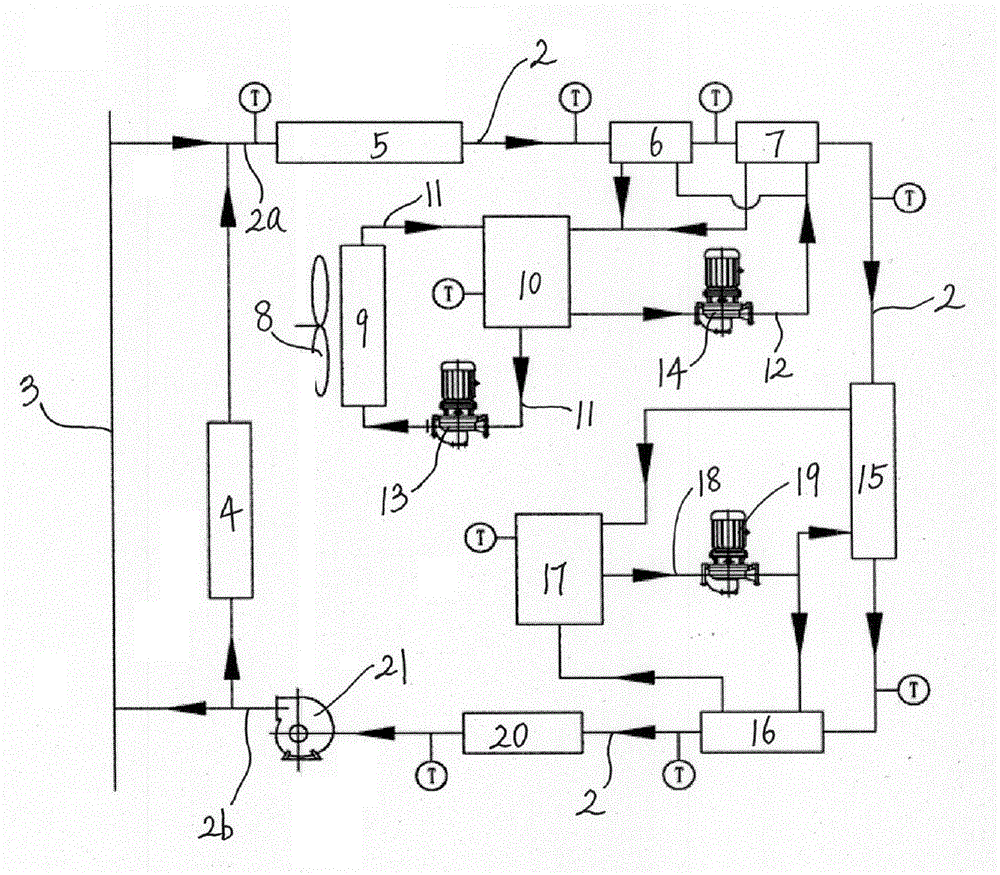

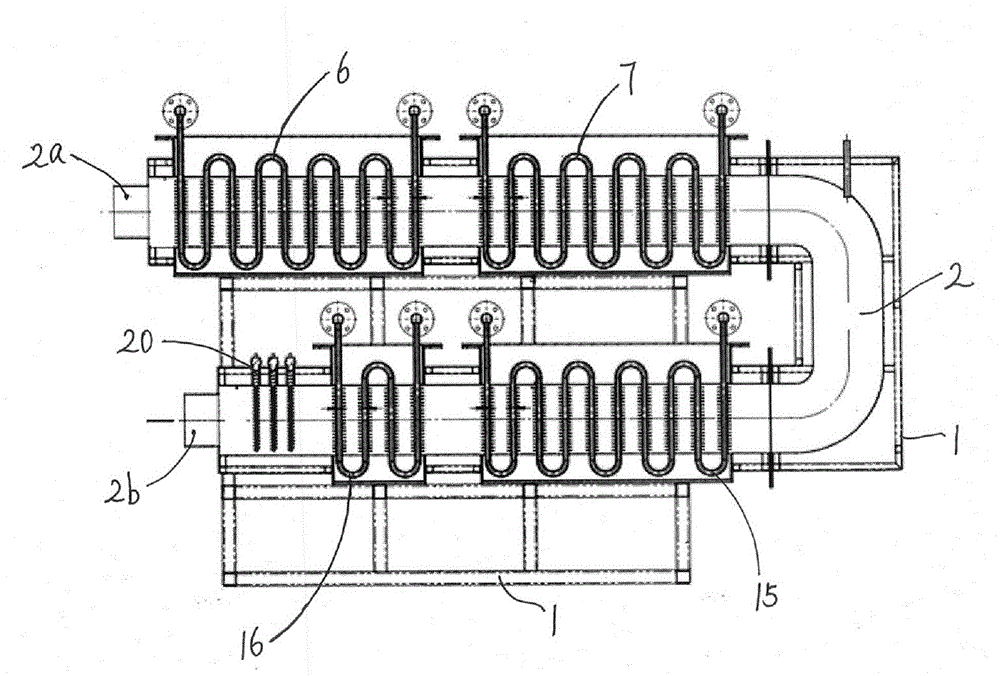

[0027] Such as figure 1 , figure 2 The low-temperature acid dew point corrosion test device for power plant boiler flue gas shown in the figure includes an experimental platform 1, a flue gas test pipeline 2, a pitot tube velocimeter 5, a cooling system, a heating system 20, an induced draft fan 21, and a measurement and acquisition system As well as the control system, the experimental platform 1 is a U-shaped frame with a horizontal opening facing the boiler flue 3. The experimental platform 1 also has a mobile bracket for easy movement. The flue gas experimental pipeline 2 is horizontally arranged with the U-shaped frame opening. To ensure that the experimental flue gas flow field meets the requirements, the flue gas experimental pipeline 2 is supported on the experimental platform 1.

[0028] The inlet port 2a and the outlet port 2b of the flue gas test pipeline 2 are connected with the boiler flue 3, specifically the boiler air preheater flue, and the Pitot tube velocim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com