Step motor-based electronic fuel injection car nozzle cleaning machine

A technology of stepping motors and cleaning machines, applied in computer control, instruments, simulators, etc., can solve problems such as unstable speed, high capacity, and deterioration of exhaust emissions, and achieve reliable, cost-effective, and simple systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Hereinafter, the present invention will be described in more detail with examples in conjunction with the accompanying drawings:

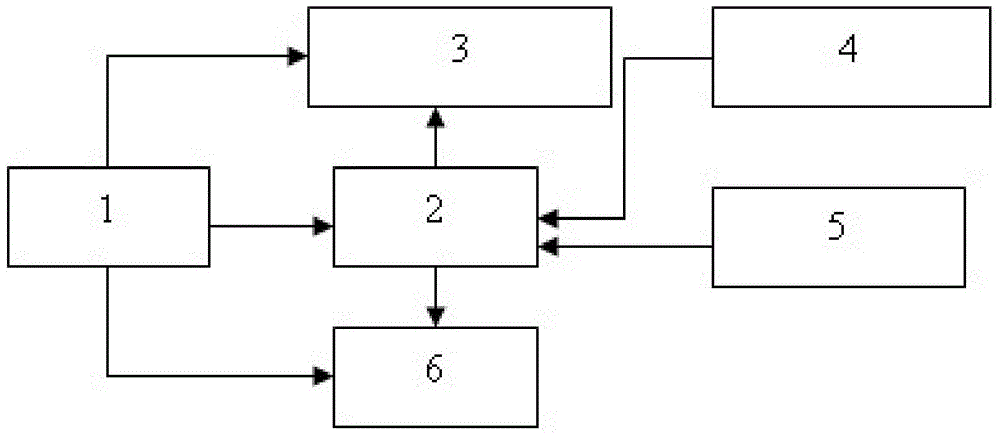

[0019] A stepper motor-based EFI automobile nozzle cleaning machine, which consists of: power circuit module 1, control module 2, timing alarm module 3, external storage module 4, man-machine interface module 5 and software execution mechanism 6, in which the power supply The circuit module 1 is connected to the control module 2, the timing alarm module 3 and the software execution mechanism 6 respectively.

[0020] The timer signal in the above-mentioned timing alarm module 3 is processed by the CPU and then displayed on the display. The timing value input by the keyboard can be displayed on the display. And output the real-time timing information to the comparator, compare with the preset value in the comparator, and then control the buzzer to alarm.

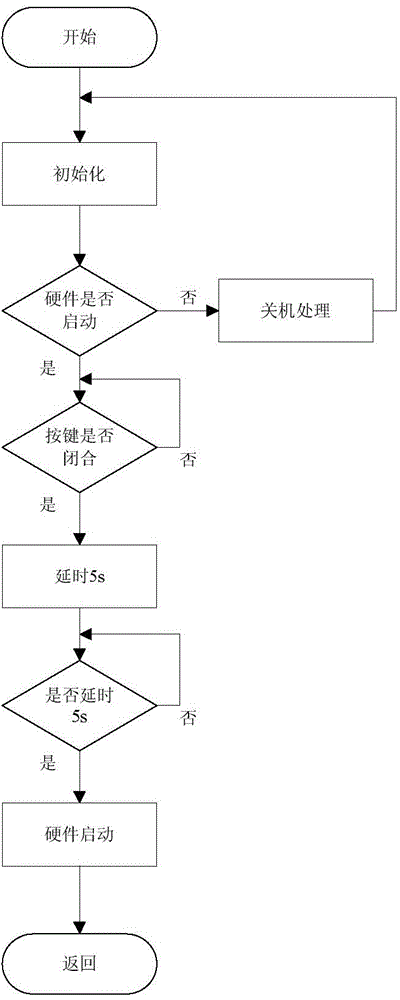

[0021] The above-mentioned software execution mechanism 6 includes the initialization of the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com