A Multifunctional Microwave Heating Reaction Control System

A reaction control system and microwave heating technology, applied in control/regulation systems, temperature control, non-electric variable control, etc., can solve the problems of inability to achieve precise control of water temperature, affecting the continuous and stable progress of the reaction, and lack of active convection devices, etc. To achieve the effect of easy implementation, simple structure and good heat transfer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

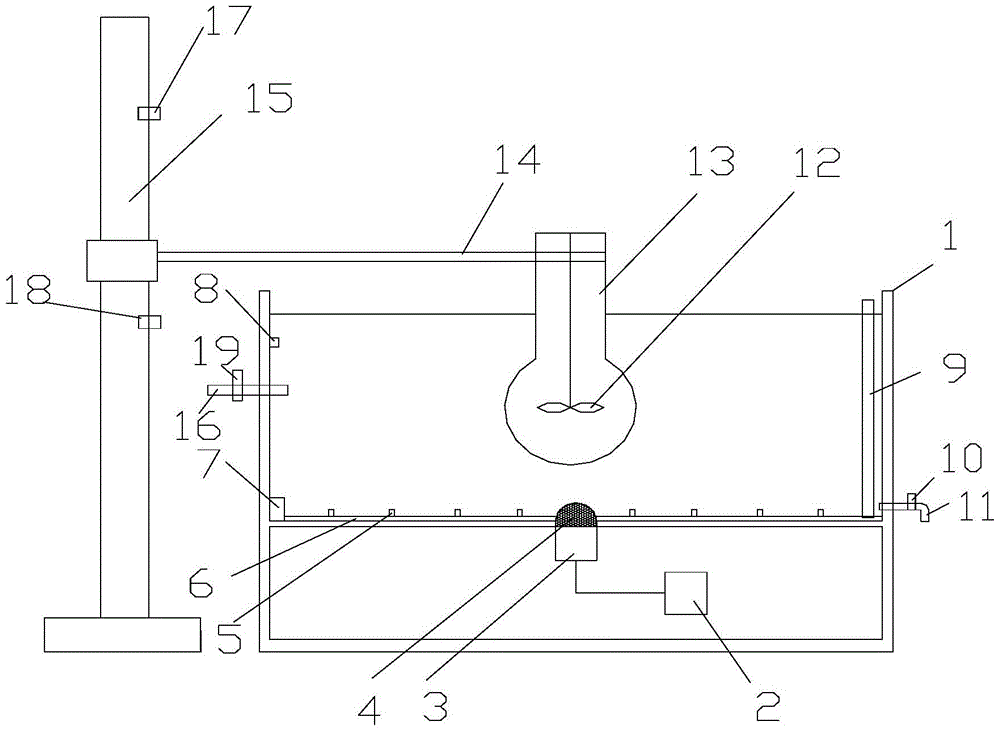

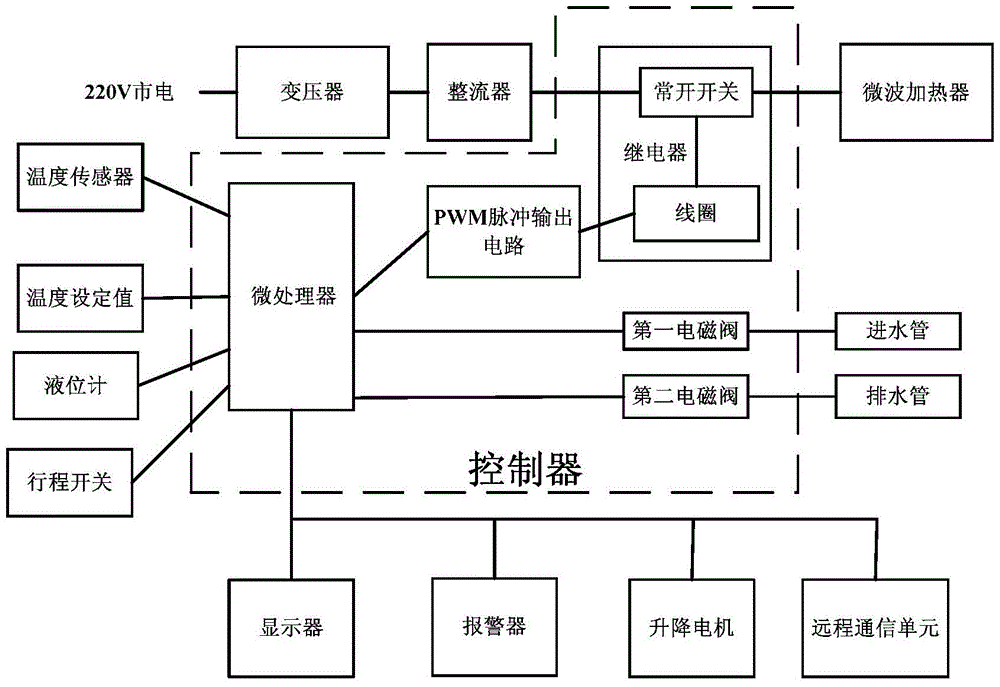

[0035] Such as Figure 1-2 , a multifunctional microwave heating reaction control system, comprising a water tank 1, a microwave heater 3, a microprocessor 2 and a water tank bottom; the water tank bottom is arranged at the bottom of the water tank for supporting the water tank; the microprocessor is fixed on the water tank bottom Middle; the microprocessor is connected with the microwave heater; the magnetron used for heating is arranged in the microwave heater; the heating cavity 4 of the microwave heater extends into the water tank from the bottom plate of the water tank; the outside of the heating cavity is covered with a layer A shielding net that can penetrate liquid; control the microwave heater to work and control the water temperature in the water tank through the microprocessor 2, and provide ambient temperature for the reaction in the reaction vessel 13;

[0036] The bottom of the water tank is provided with a circulation pump 7 and a pipeline 6 connected to the out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com