Breathable sagger for roasting of electronic materials

An electronic material and air-permeable technology, which is applied in the direction of furnace components, charge manipulation, furnace, etc., can solve the problems such as the influence of firing electronic materials in the bowl, and achieve the effect of facilitating sintering, improving the rate of high-quality products, and uniform heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

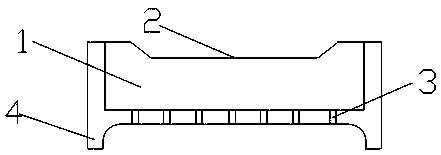

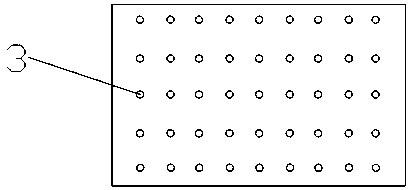

[0013] Example 1, such as Figure 1~2 As shown, a gas-permeable sagger for roasting electronic materials includes a sagger body 1, which is surrounded by a sag bottom and walls on four sides. The air vent 2 is sunken, and a transparent small hole 3 is provided on the bottom of the box.

Embodiment 2

[0014] Embodiment 2, with reference to Example 1, a vent is provided on the four walls of the sagger body, the cross section of the vent is preferably an isosceles trapezoid, and the length of the vent accounts for 20-90% of the side length of the sagger, The depth accounts for 5%-75% of the height of the box wall, the diameter of the transparent small hole is 0.8-5mm, and the height of the supporting feet is 1-50mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com