Thin-wall part supporting device and milling stability forecasting method

A technology for supporting devices and thin-walled parts, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problems of prone to chattering, increasing manufacturing costs, affecting the surface quality of workpieces, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

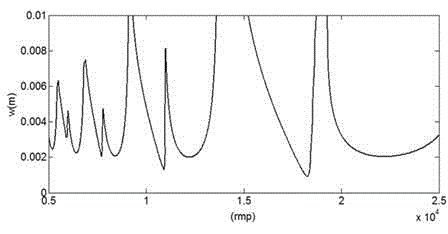

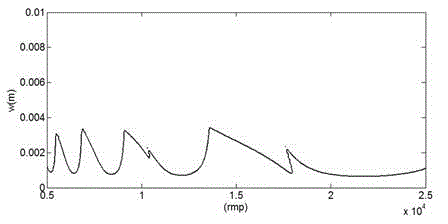

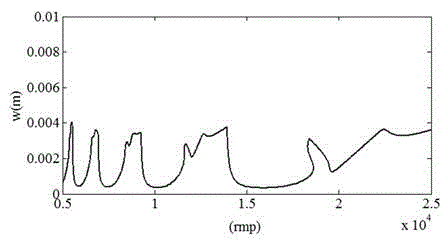

Image

Examples

Embodiment Construction

[0073] One, the embodiment of device of the present invention:

[0074] Such as Figure 4 , 5 As shown, a support device for thin-walled parts includes a support platform 3, a first loop 1, a second loop 2, an X-direction slide 5, a matching buckle 4 with a through hole 6, and a first slide 7 -1, the second slideway 7-2, the third slideway 8-1, the fourth slideway 8-2 and the supporting mechanism for fixing and supporting thin-walled parts;

[0075] The first ring road 1 and the second ring road 2 are concentric and sequentially arranged on the support table 3, and the X-direction slideway 5 is arranged on the support table 3 and passes through the first ring road 1 and the second ring road 2 The center of the circle, the first slideway 7-1 and the second slideway 7-2 are symmetrically arranged on both sides of the X-direction slideway 5, and the third slideway 8-1 and the fourth slideway 8-2 are symmetrically arranged on On both sides of the X-direction slideway 5, the mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com