Main loop circulating device for pool type liquid heavy metal cooling reactor

A liquid heavy metal and circulation device technology, applied in cooling devices, reactors, reducing greenhouse gases, etc., can solve problems such as low economic efficiency, large internal space in the reactor, and reduced seismic performance of the reactor, so as to improve economic efficiency and simplify the system structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

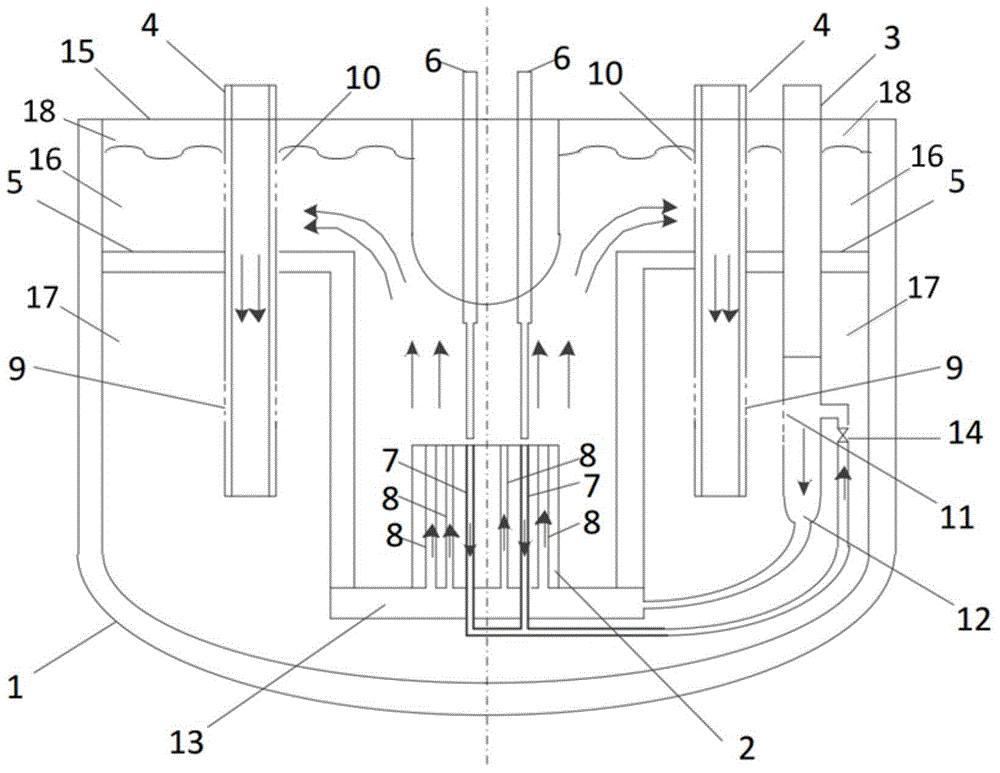

[0016] Such as figure 1 As shown, the present invention is a kind of main circuit circulation device for pool type liquid heavy metal cooling reactor, including container 1, reactor core 2, main pump 3, heat exchanger 4, thermal partition 5, control rod driving mechanism 6, control Rod assembly 7, fuel assembly 8, heat exchanger outlet 9, heat exchanger inlet 10, main pump inlet 11, main pump outlet 12, grid header 13, throttle valve 14, stack top cover 15, Hot pool 16, cold pool 17, cover gas 18; grid header 13 is used to support core 2, thermal partition 5 fixes grid header 13 at the bottom of container 1, and thermal partition 5 connects main circuit coolant It is divided into two parts: the upper hot pool 16 and the lower cold pool 17. Covering gas 18 is filled between the stack roof 15 and the hot pool 16. The control rod assembly 7 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com