Cooling element

A technology for cooling components and electrical components, used in electrical components, cooling/ventilation/heating transformation, semiconductor devices, etc., can solve the problems of difficulty in ensuring sufficient cooling of electrical components and insufficient cooling performance, and achieve the effect of improving cooling capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

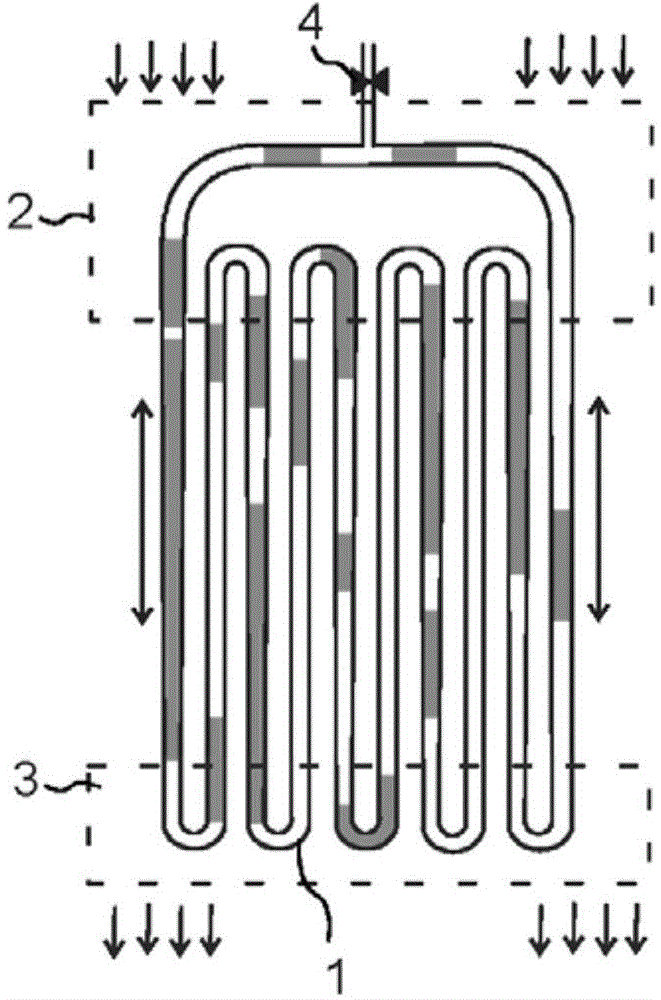

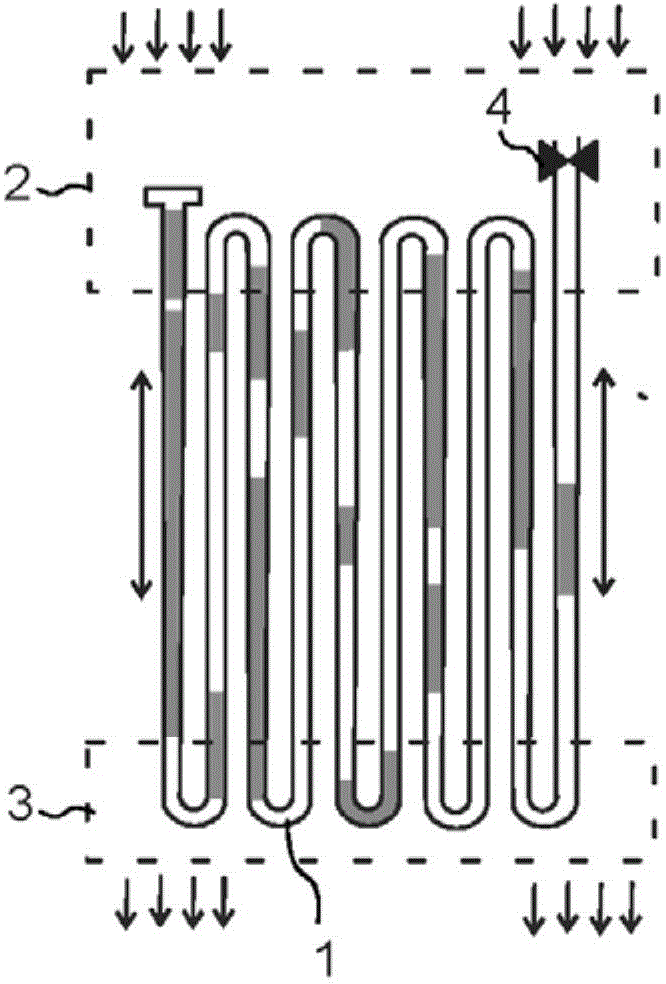

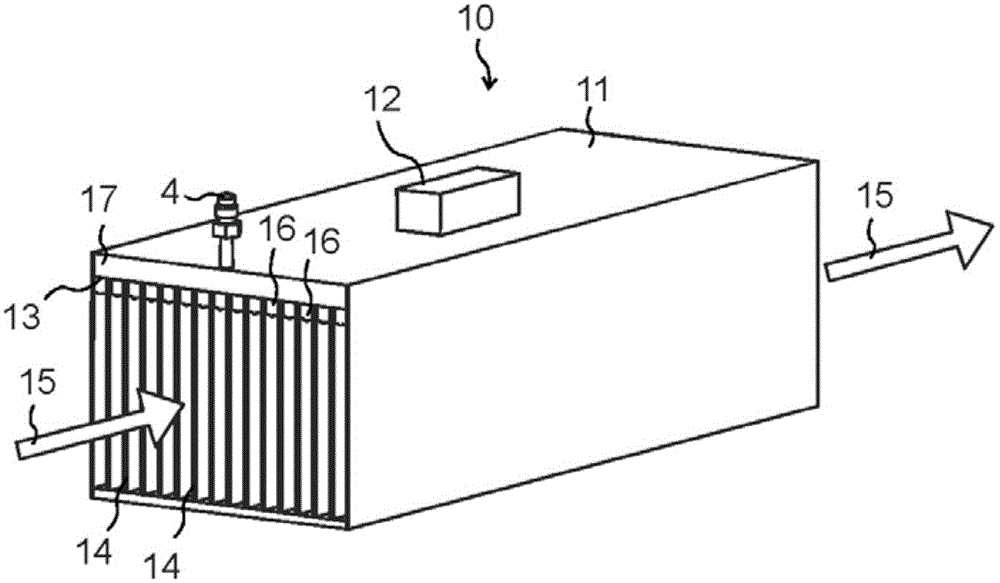

[0013] Figure 1a and Figure 1b The working principle of a pulsating heat pipe (PHP) is shown. Figure 1a shows the closed loop PHP and Figure 1b An open loop PHP is shown.

[0014] The pulsating heat pipe contains a tortuous flow channel 1 with capillary dimensions, in other words, a sufficiently small cross-section such that capillary forces dominate gravity. A suitable fluid can be introduced into the flow channel 1 via the injection valve 4 . Thus, the fluid moves by pulsation caused by pressure instability. Oscillations are generated in the small channel loop due to bi-directional expansion of the steam inside the channel. During operation, liquid plugs and elongated vapor bubbles will oscillate between cold and hot regions due to hydrodynamic instability induced by the rapid expansion of gas bubbles confined in small channels, and thus provide little dependence on The fluid velocity due to gravity. This makes the pulsating heat pipe rather insensitive to orientati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com