Tyre for heavy civil engineering vehicle

A heavy-duty vehicle and civil engineering technology, applied in the crown field of tires, can solve the problems of excessively hard crown reinforcements and shortened life of carcass reinforcements, and achieves good productivity, is beneficial to productivity, and reduces the risk of openings.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

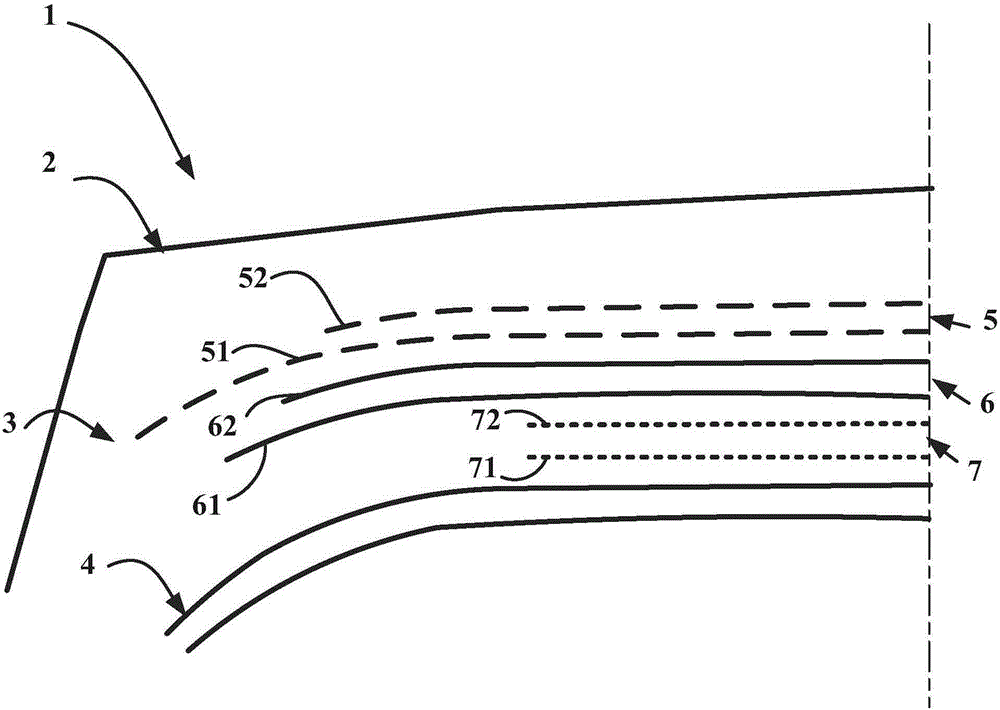

[0061] figure 1 Shows a meridional half-section of the crown of a tire 1 for civil engineering heavy vehicles, said tire comprising: - a tread 2, a crown reinforcement 3 and a carcass reinforcement 4, said crown reinforcement 3 being radially Upwardly inside the tread 2, said carcass reinforcement 4 is radially inside the crown reinforcement 3,

[0062] - The crown reinforcement 3 includes radially from the outside to the inside

[0063] - a protective reinforcement 5 comprising at least one protective layer (51, 52) formed by elastic metal reinforcements forming an angle with the circumferential direction at least equal to 10°,

[0064] - a working reinforcement 6 comprising at least two working layers (61, 62) formed of non-elastic metal reinforcements crossing from one working layer to the other and form an angle of at most 60° with the circumferential direction,

[0065] - an additional reinforcement 7, centered on the equatorial plane of the tyre, comprising at least o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com