Pump blade for submersible pump and submersible pump with same

A submersible pump and vane technology, which is applied to the components, pumps, pump devices and other directions of pumping devices for elastic fluids, can solve problems such as the existence of limitations in the settings, the inability to offset the load, and the reduction of radial loads, so as to reduce losses, The effect of shortening the length of the flow path and reducing noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

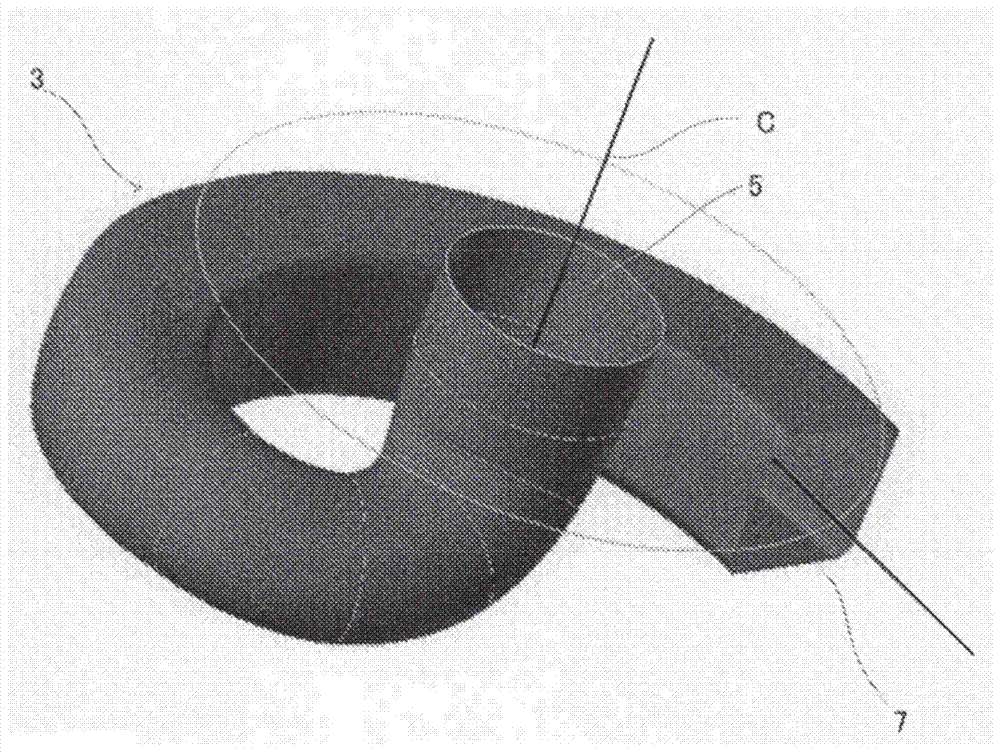

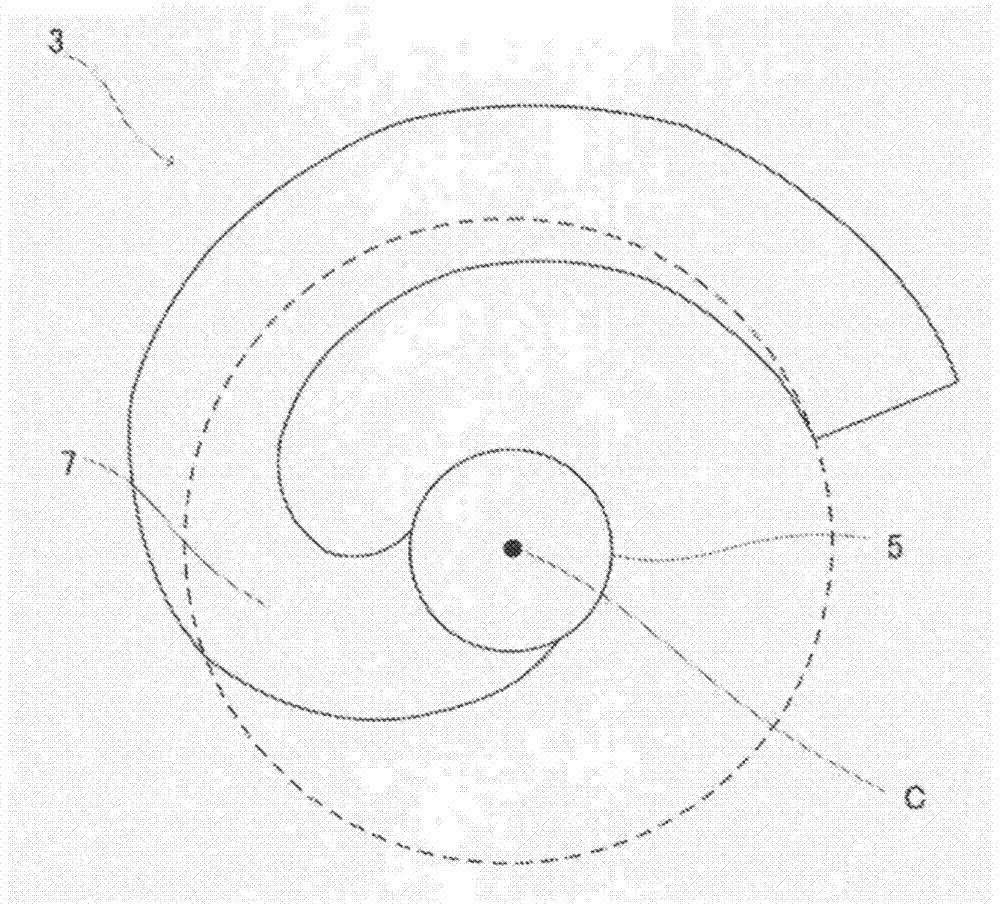

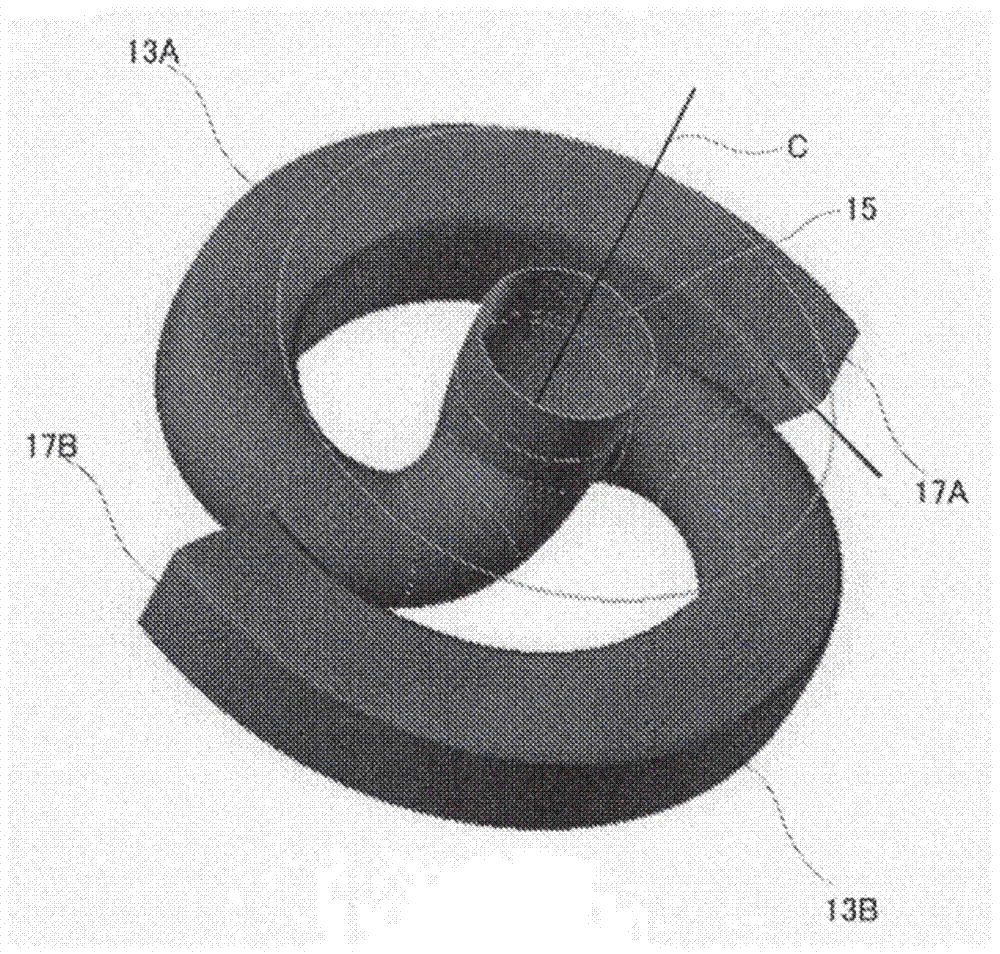

[0045] Next, a pump blade according to an embodiment of the present invention will be described with reference to FIGS. 1 to 8 .

[0046] [the whole frame]

[0047] The pump vane of this embodiment has a plurality of flow paths communicating with the suction port coaxial with the rotation axis and the discharge port on the outer periphery, and the flow paths are logically arranged at equal angular intervals with respect to the rotation axis. Although the number of flow paths is not particularly limited, the cases shown in FIGS. 3 to 5 are embodiments in which there are two flow paths, and the cases shown in FIGS. 6 to 8 are embodiments in which there are three flow paths. The flow path is curved in a curved shape between the suction port and the discharge port. This pump vane can be manufactured by casting as an example. However, other metallic or non-metallic materials may be used as long as strength and corrosion resistance can be ensured.

[0048] [flow path]

[0049] F...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com