A desorption tower and its heating gas inlet channel

A technology for heating gas and air intake channels, which is applied to the separation of dispersed particles, chemical instruments and methods, and separation methods. It can solve problems such as uneven flow rates of heating gas, and achieve the effects of reducing technical costs and avoiding technical risks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

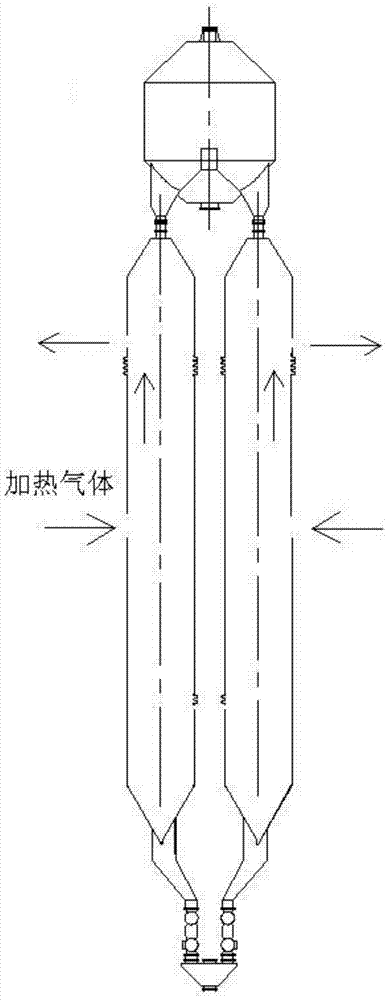

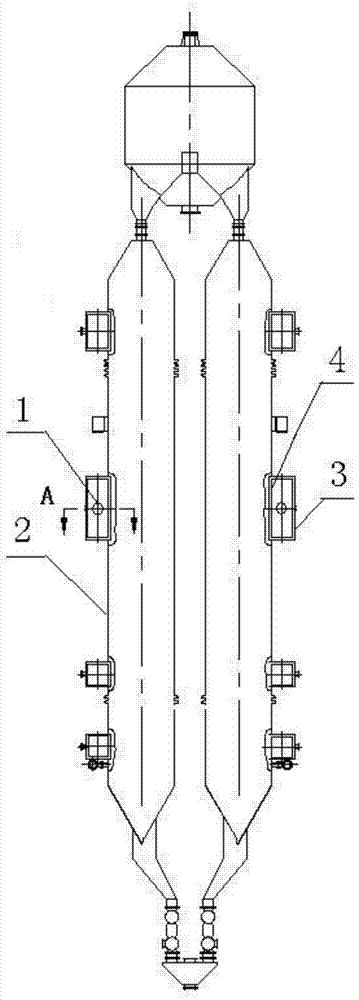

[0037] See diagram 2-1 , which is a schematic diagram of the overall structure of the analytical tower device described in this embodiment.

[0038] The analysis tower device includes two analysis tower main bodies, so as to control the safety height of the tower body on the basis of satisfying the system analysis capability. The activated carbon that has completed the adsorption enters the heat exchange tubes in the main bodies of the two desorption towers through the silo. In the main bodies of the two desorption towers, the heat exchange tubes are heated by the heating gas, thereby indirectly heating the activated carbon in the desorption towers. The activated carbon is in the high temperature zone (320 -490℃) for a certain period of time, so that the adsorbed SO 2 When harmful substances are decomposed and discharged at high temperature, the adsorption function of activated carbon can be restored and the regeneration of activated carbon can be realized; the activated car...

Embodiment 2

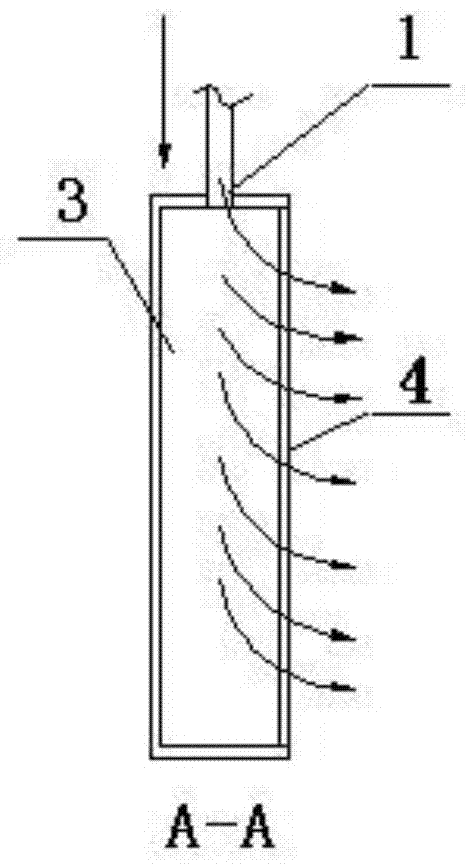

[0050] The schematic diagram of the overall structure of the analytical tower device described in this embodiment is as follows diagram 2-1 As shown, the difference from the first embodiment lies in the structure of the flow equalizer 4, corresponding to the situation where the heated gas enters the intake buffer chamber 3 in the horizontal direction, the flow balance plate 4 described in this embodiment is distributed with vertical installation In addition, in the air intake direction of the horizontal air inlet, the inclination angle of the louvers gradually increases from the middle to both ends, so that when the gas in the middle part with a fast circulation velocity passes through the louvers with a small inclination angle in the middle, the speed will be affected by a certain amount. However, when the gas at the two ends with a relatively slow flow velocity passes through the louvers with a large inclination angle, it can relatively maintain its original velocity. For de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com