Preparation method of power type lithium thionyl chloride battery positive electrode

A lithium thionyl chloride battery, power technology, applied in electrode manufacturing, battery electrodes, electrode rolling/calendering, etc., can solve the problems of positive electrode powder loss, flanging, falling off, etc., to achieve the effect of increasing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A method for preparing a positive electrode of a power type lithium thionyl chloride battery, comprising the following steps:

[0043] 1) Mixing

[0044] Mix 1000g acetylene black, 140g absolute ethanol, 5400g pure water, 70g copper powder, and 90g polytetrafluoroethylene emulsion (60wt%) into a uniform semi-dry material;

[0045] Put the mixed semi-dry material into a drying oven at 70°C for 15 hours;

[0046] 2) Internet access

[0047] Use a high-speed rotary blade crusher to crush the dried material into fine particles with a particle size of 0.2mm to 1.2mm;

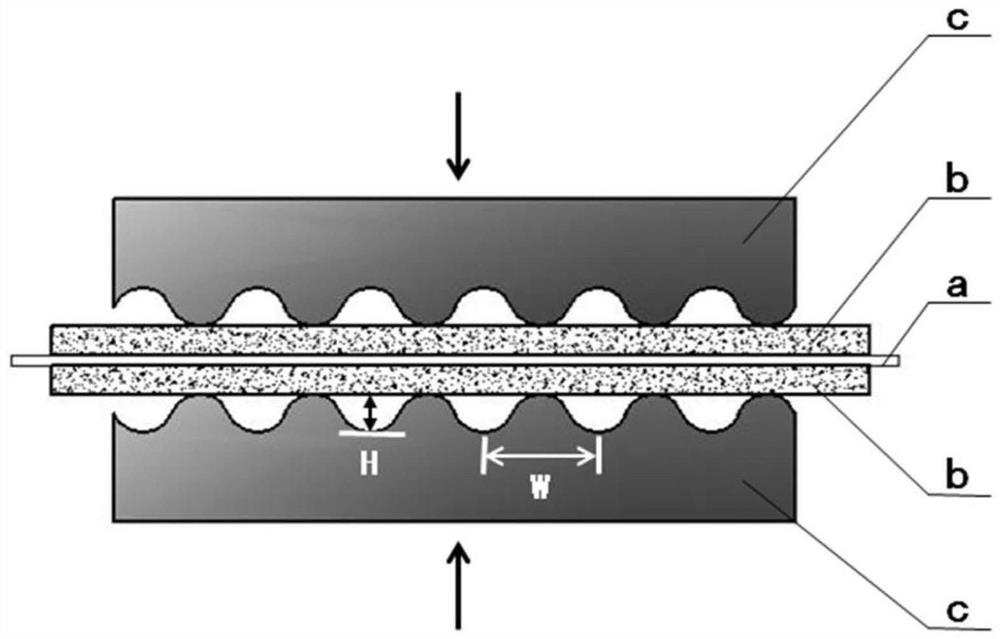

[0048] Fill the fine particle material evenly on both sides of the nickel expanded mesh through the packing tool, and use the roller press to compact the filled material. The density of the material after compaction is: 0.29g / cm 3 ;

[0049] 3) Fibrosis treatment

[0050] Put the filled and compacted positive electrode nickel mesh into the oven and bake at 240°C for 30min;

[0051] Soak the baked positive ...

Embodiment 2

[0057] A method for preparing a positive electrode of a power type lithium thionyl chloride battery, comprising the following steps:

[0058] 1) Mixing

[0059] Mix 1000g acetylene black, 230g absolute ethanol, 4600g pure water, 85g nickel powder, and 100g polytetrafluoroethylene emulsion (60wt%) into a uniform semi-dry material;

[0060] Put the mixed semi-dry material into a drying oven at 60°C for 15 hours;

[0061] 2) Internet access

[0062] Use a high-speed rotary blade crusher to crush the dried material into fine particles with a particle size of 0.2mm to 1.2mm;

[0063] Fill the fine particle material evenly on both sides of the nickel expanded mesh through the packing tool, and use the roller press to compact the filled material. The density of the material after compaction is: 0.30g / cm 3 ;

[0064] 3) Fibrosis treatment

[0065] Put the stuffed and compacted positive electrode nickel mesh into the oven and bake at 175°C for 1 hour;

[0066] Soak the baked posi...

Embodiment 3

[0072] A method for preparing a positive electrode of a power type lithium thionyl chloride battery, comprising the following steps:

[0073] 1) Mixing

[0074] Mix 1000g of acetylene black, 180g of absolute ethanol, 5200g of pure water, 65g of copper powder, and 120g of polyvinylidene fluoride emulsion (50wt% to 55wt%) to form a uniform semi-dry material;

[0075] Put the mixed semi-dry material into a drying oven at 70°C for 15 hours;

[0076] 2) Internet access

[0077] Use a high-speed rotary blade crusher to crush the dried material into fine particles with a particle size of 0.2mm to 1.2mm;

[0078] Fill the fine particle material evenly on both sides of the nickel expanded mesh through the packing tool, and use the roller press to compact the filled material. The density of the material after compaction is: 0.29g / cm 3 ;

[0079] 3) Fibrosis treatment

[0080] Put the filled and compacted positive nickel mesh into the oven and bake at 245°C for 30min;

[0081] Soak...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com