Internal washing machine for barreled water barrels

A technology of internal washing machine and barreled water, which is applied in the direction of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of single function, low working efficiency of internal washing machine, and insufficient automation, and achieve cleaning High efficiency, ingenious design, good cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

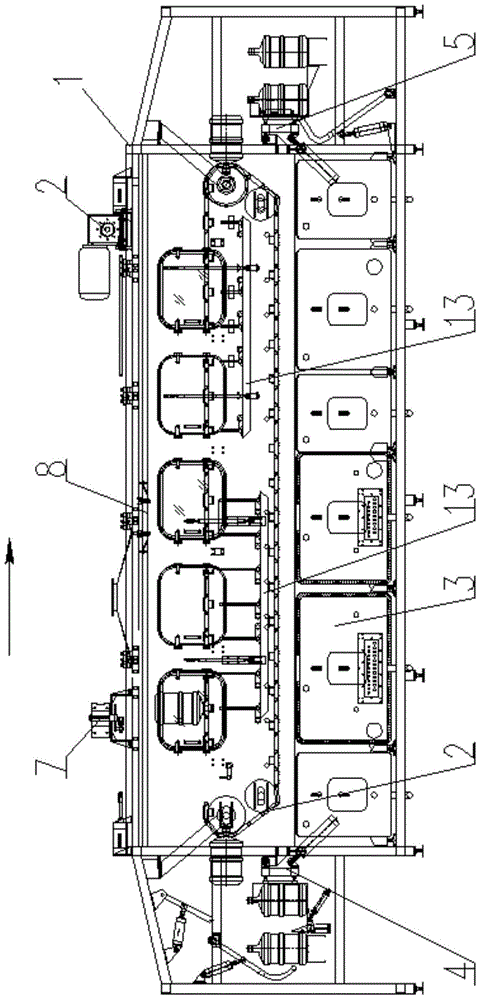

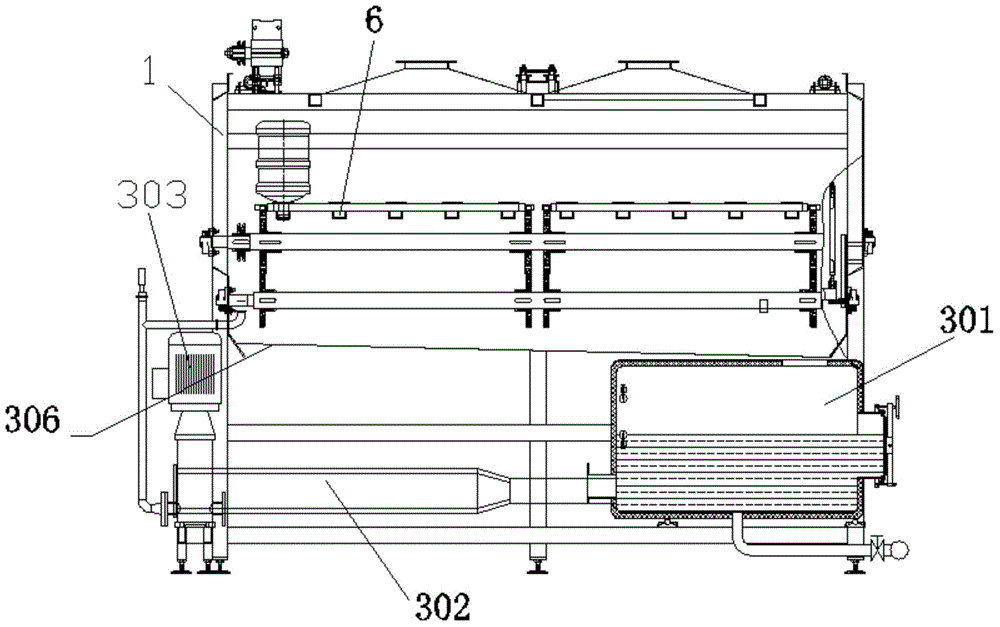

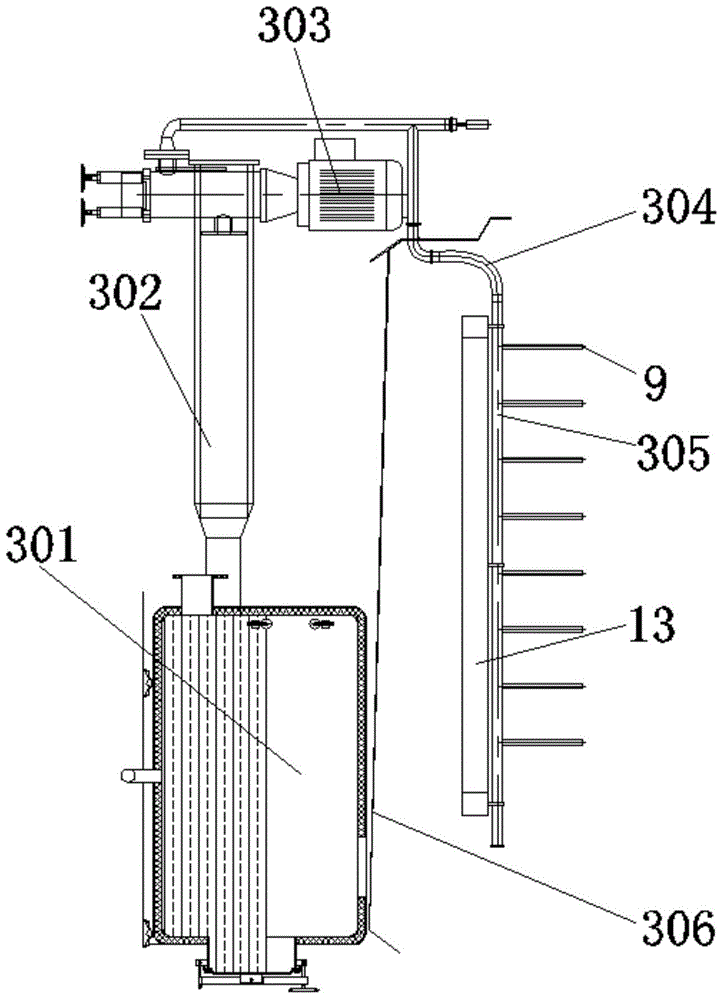

[0035] Embodiment 1: as Figure 1 to Figure 12 As shown, the present invention is a barreled water bucket internal washing machine, which includes a frame 1, and it also includes an inner washing machine barrel upper mechanism 4, an inner washing conveyor chain mechanism 2, a water circulation system 3, a lifting Frame 13, inner washing machine lower barrel mechanism 5, chain lifting mechanism 7 and liftable barrel pressing mechanism 8, said inner washing machine upper barrel mechanism 4, inner washing conveyor chain mechanism 2, inner washing machine lower barrel mechanism 5 press the bucket The conveying direction is arranged sequentially, the water circulation system 3 is arranged below the inner washing conveying chain mechanism 2, the chain lifting mechanism 7 is arranged on the top of the frame 1, and the barrel pressing mechanism 8 is arranged above the inner washing conveying chain mechanism 2 , the water circulation system 3 includes the nozzle 9 of the inner washing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com