Low-slitter-edge radius tool

A technology of corner cutter and edge circle, applied in metal processing and other directions, can solve the problems of not satisfying product appearance, use safety, material waste, etc., and achieve the effect of saving strip bag materials, simplifying processing procedures, and ensuring the effect of slitting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

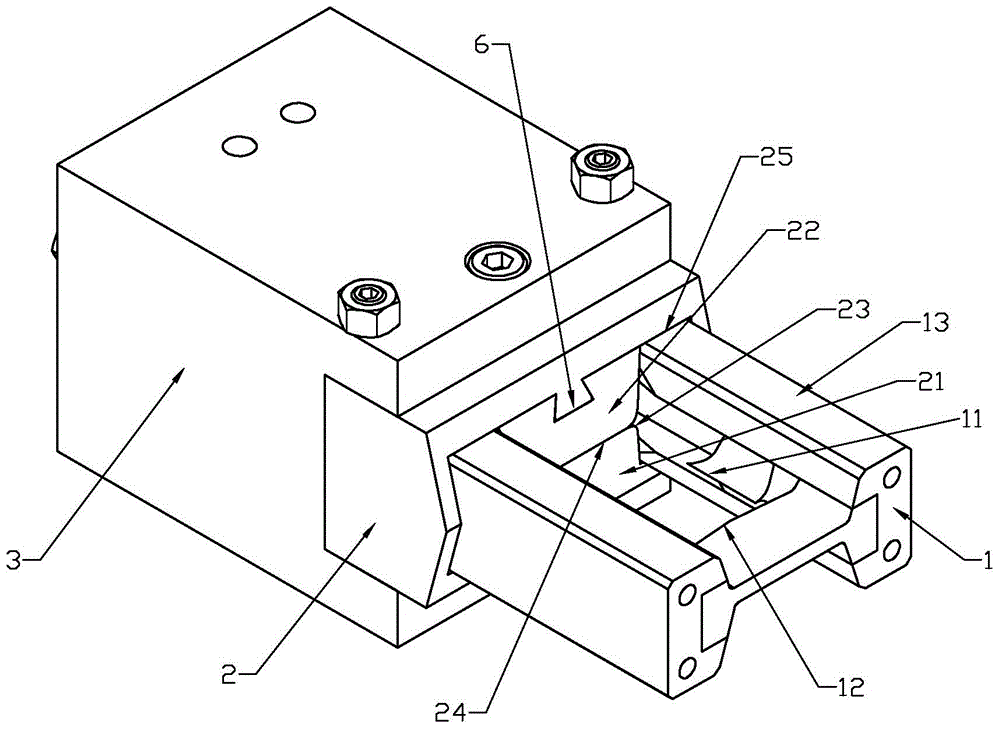

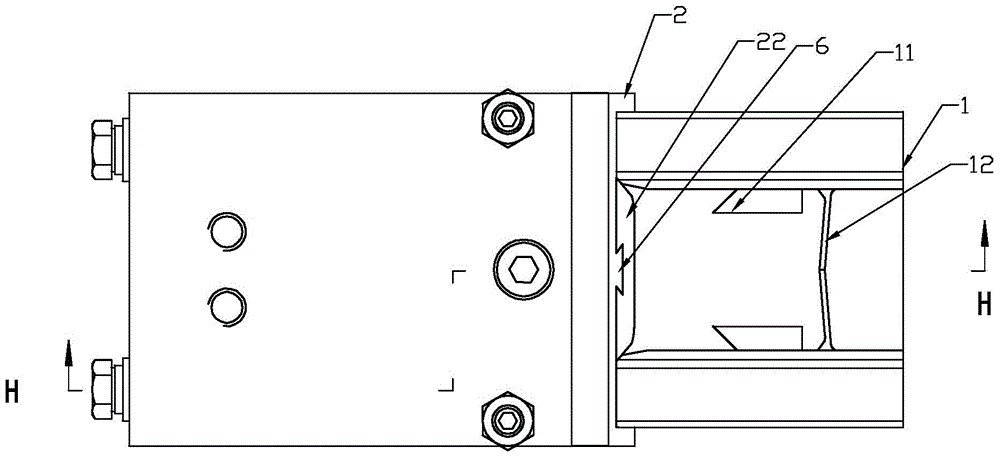

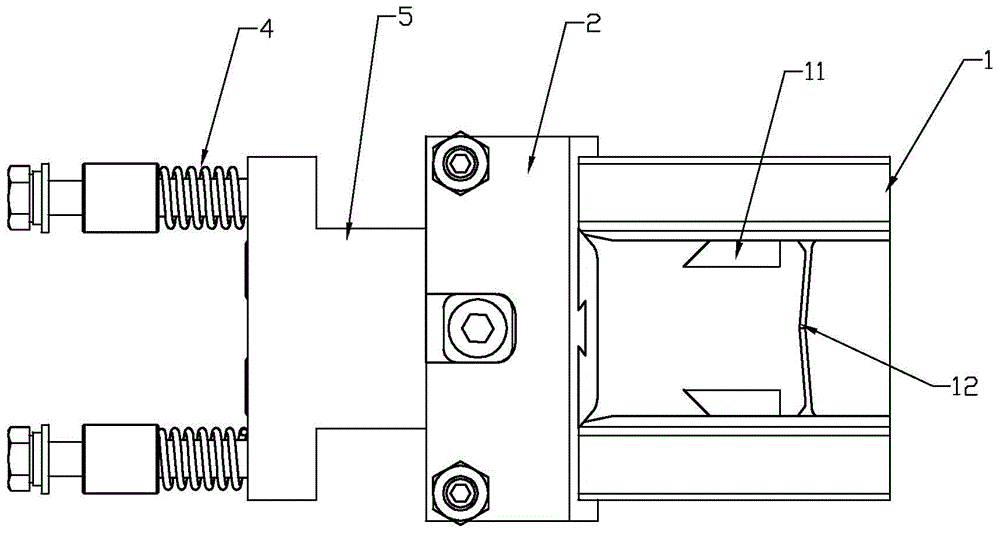

[0019] Such as figure 1 , figure 2 , Figure 4 As shown, the low waste round corner cutter includes a male mold 1 and a female mold 2 that can move relatively back and forth; the female mold is composed of a fixed female mold 21 and a movable female mold 22 that are aligned with each other. The fixed female mold 21 is fixedly installed on the mold base 3, and the movable female mold 22 can move back and forth relative to the fixed female mold 21; when the movable female mold is at the front limit position, both sides of the movable female mold 22 and the fixed female mold 21 Spliced to form a complete female mold fillet cutting edge 23 (see Figure 7 ), both sides of the rear part of the male mold 1 have a pair of male mold fillet cutting edges 11 that are matched with the female mold fillet cutting edges 23 (see Image 6 ), so that when the male mold moves relative to the female mold, the rounded cutting edges of the male mold and the female mold can cut the corners of two a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com