Graphite heat conduction film compound block and manufacturing method thereof

A technology of graphite heat conduction film and manufacturing method, which is applied in chemical instruments and methods, cooling/ventilation/heating transformation, lamination devices, etc., and can solve the problem that the thermal conductivity in the thickness direction is only 5-10W/mK

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

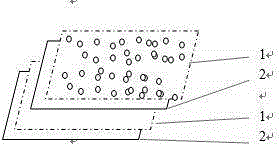

Image

Examples

Embodiment Construction

[0020] The graphite thermal conductive film composite block of the present invention and its manufacturing method will be described in further detail below.

[0021] The present invention will be described in more detail below with reference to the accompanying drawings, which show preferred embodiments of the present invention. It should be understood that those skilled in the art can modify the present invention described herein and still achieve the beneficial effects of the present invention. Therefore, the following description should be understood to be widely known to those skilled in the art, and not as a limitation to the present invention.

[0022] For clarity, not all features of actual embodiments are described. In the following description, well-known functions and structures are not described in detail because they may confuse the present invention due to unnecessary details. It should be considered that in the development of any actual embodiment, a large number of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com