Submersible multi-functional wharf boat

A multi-functional and barge technology, applied in the field of barges and submersible multi-functional barges, can solve the problems of difficult withdrawal, large manpower demand, limited number of equipment, etc., and achieve the effect of safe splicing, high degree of automation, and convenient splicing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with drawings and embodiments.

[0017] Barge main body 1 adopts steel structure, rectangular shape, length 50m, molded width 10m, molded depth 2m, external power supply, power supply is 380V, and the driving mode is towing type.

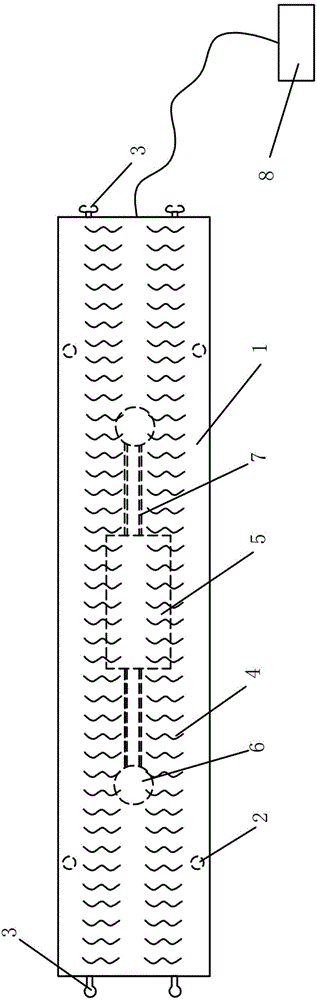

[0018] Such as figure 1 As shown, the present invention includes a pontoon main body 1 and an anchoring device 2, a coupling device 3, an anti-skid device 4, a pumping station system 5, a drainage device 6, a pipeline system 7, and a control system 8 which are all arranged on the pontoon main body 1; 1 is an ordinary floating wharf pontoon, which is constructed with steel structure or reinforced concrete structure, and designed and constructed according to the specifications; the anchor device 2 is 4 sets of electro-hydraulic struts, which are symmetrically arranged at the bottom of the pontoon main body 1, and can be Independently controlled, automatically vertically teles...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com