Aluminum alloy fluency strip for fluency cargo shelf and arrangement method thereof

A fluent strip and aluminum alloy technology, applied in the field of warehousing and logistics, can solve the problems of weak load-bearing capacity, complicated disassembly and assembly procedures, and inconvenient use, and achieve light and easy installation, good dimensional stability and electrical insulation, and easy installation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

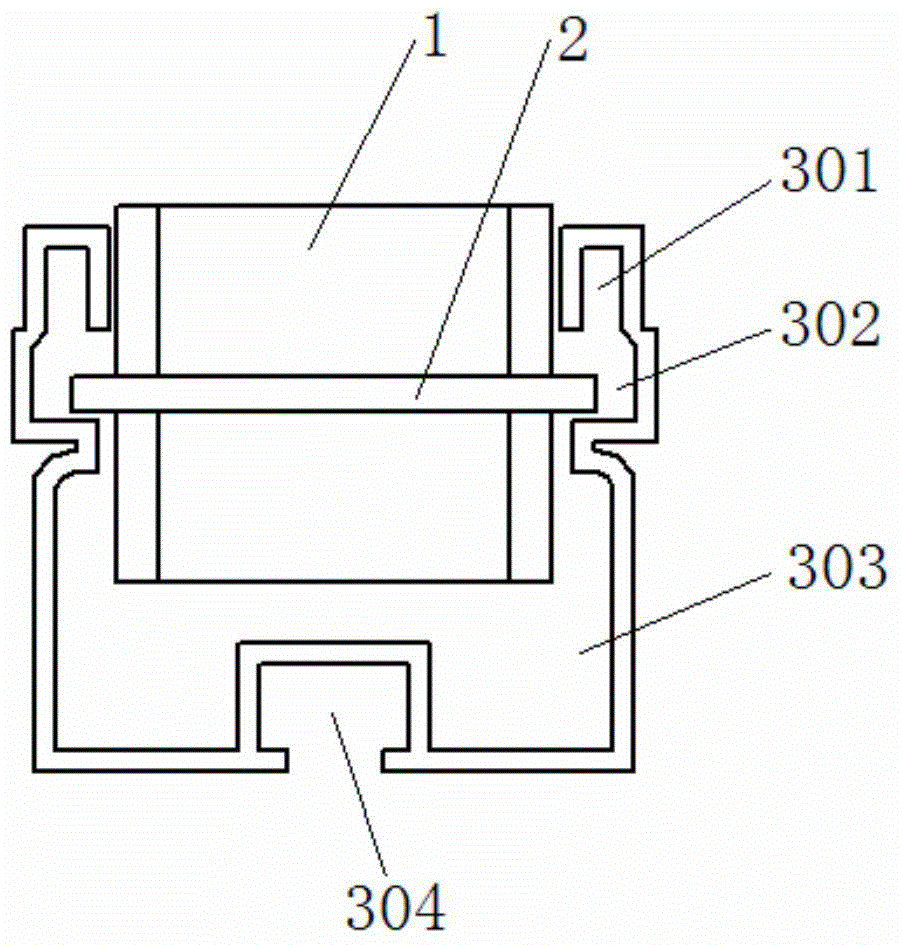

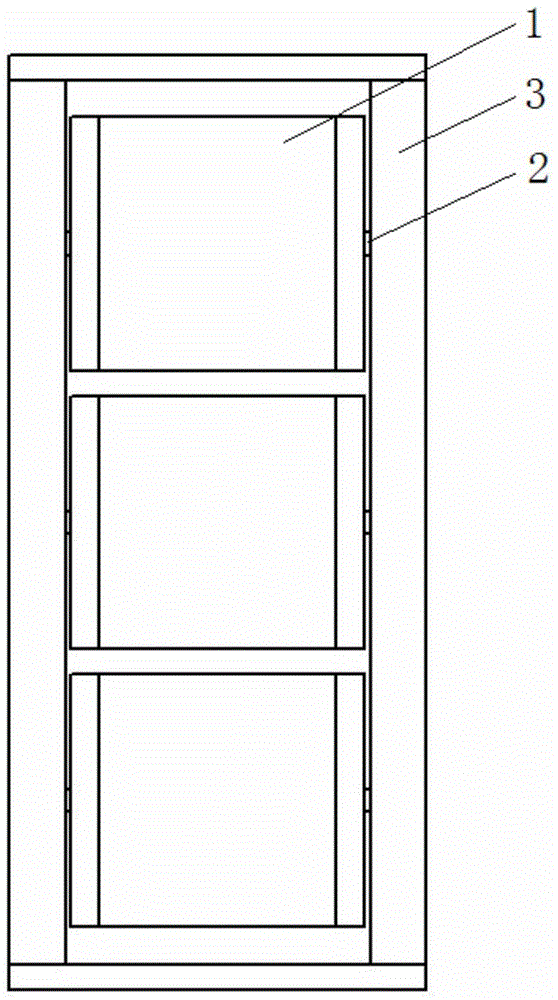

[0022] This embodiment provides an aluminum alloy fluent bar for fluent shelves, the structure is as follows figure 1 , figure 2 As shown, it includes a plurality of rollers 1, roller shafts 2 and slide rails 3. The roller 1 is a cylindrical structure, and the horizontal center line of the roller 1 is provided with a through groove. 1 is installed on the slide rail 3 through the roller shaft 2, and the rollers 1 slide rail 3 are arranged at equal intervals in the length direction. The bottom 304 of the slide rail, the upper part 301 of the slide rail and the middle part 302 of the slide rail are used for the installation and movement of the roller shaft 2. The bottom 304 of the slide rail protrudes upwards to form a rectangular installation convex groove, and the two ends of the opening surface of the rectangular installation convex groove are respectively connected The short side end of the L-shaped structure of the lower part 303 of the slide rail.

[0023] The aforementi...

Embodiment 2

[0026] This embodiment provides a method for setting aluminum alloy fluent strips for fluent shelves. The structure is as follows figure 1 , figure 2 As shown, the method is as follows:

[0027] Connect the through groove at the position of the horizontal middle line of the roller 1 to the roller shaft 2, and set aside;

[0028] The roller 1 is installed on the slide rail 3 through the roller shaft 2, and the roller 1 slide rail 3 is arranged at equal intervals in the length direction, and the axial limit is carried out by the upper part 301 of the slide rail, for standby;

[0029] The slide rails 3 obtained above are respectively installed between the front beam and the rear beam of the fluent rack respectively, and are arranged with a slope of 3°.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com