Cold-mixing and cold-paving asphalt mixture and preparation method thereof

A technology of cold laying asphalt and mixture, applied in the field of asphalt pavement engineering, can solve the problems of high pollution, high labor, high cost, etc., and achieve the effects of improving fatigue resistance, prolonging service life, and increasing supply range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

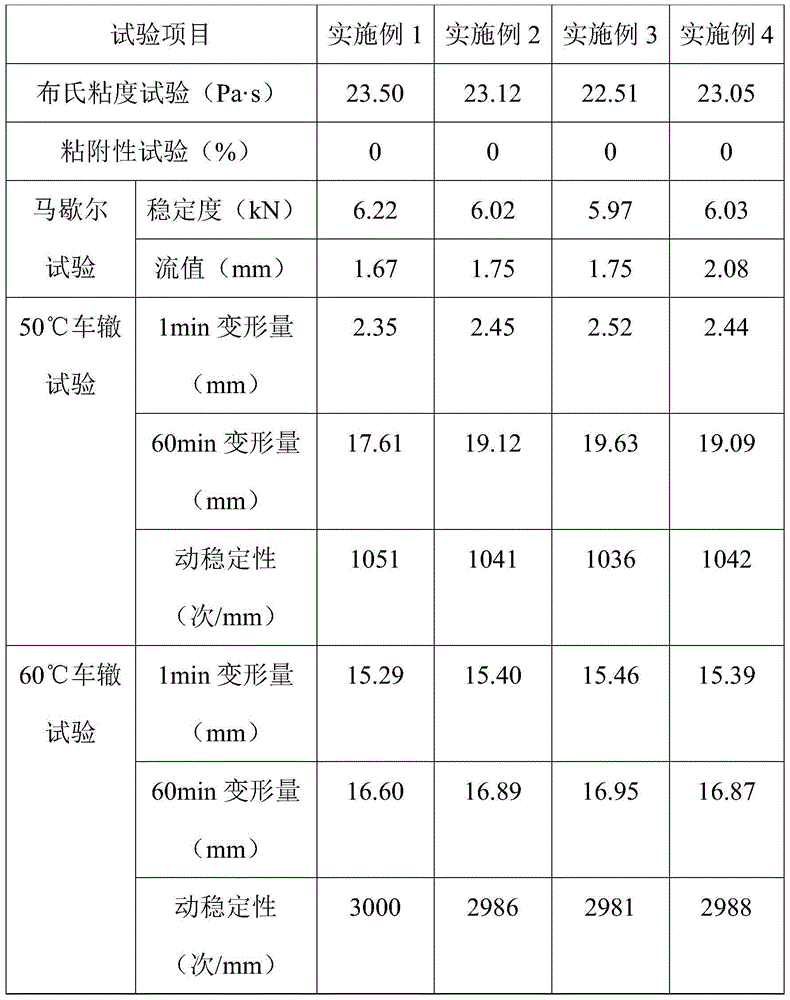

Examples

Embodiment 1

[0023] A preparation method for cold-mixed cold paving asphalt mixture, comprising the following steps:

[0024] (1) Crush the granite into two kinds of stones with a particle size of 5-10mm and 2.3-5mm, and then weigh 7330kg of stones with a particle size of 5-10mm, 1800kg of stones with a particle size of 2.3-5mm, and a particle size of 0.1 - 300kg of 2.3mm quartz sand, 100kg of mineral powder ground into limestone with a particle size of less than 0.075mm, mixed evenly, dried to make the water content less than 15%, cooled to room temperature to obtain aggregate, and set aside;

[0025] (2) Heat 470kg of asphalt to 130-150°C;

[0026] (3) Add the additive to the asphalt and stir evenly;

[0027] Wherein, the additive amount is 9.3% of the asphalt additive amount; the additive is composed of the following components and the parts by weight of each component are: 20 parts of cyclobutane, 5 parts of polyethylene, 1 part of terpene resin, 74 parts of diesel oil ;

[0028] (4...

Embodiment 2

[0030] A preparation method for cold-mixed cold paving asphalt mixture, comprising the following steps:

[0031] (1) Crush the granite into two kinds of stones with a particle size of 5-10mm and 2.3-5mm, and then weigh 7330kg of stones with a particle size of 5-10mm, 1800kg of stones with a particle size of 2.3-5mm, and a particle size of 0.1 - 300kg of 2.3mm quartz sand, 100kg of mineral powder ground into limestone with a particle size of less than 0.075mm, mixed evenly, dried to make the water content less than 15%, cooled to room temperature to obtain aggregate, and set aside;

[0032] (2) Heat 470kg of asphalt to 130-150°C;

[0033] (3) Add the additive to the asphalt and stir evenly;

[0034] Wherein, the addition amount of the additive is 10% of the bitumen addition amount; The additive is made up of the following components and the parts by weight of each component are: 20 parts of cyclobutane, 5 parts of polyethylene, 1 part of terpene resin, 74 parts of plastic oil ...

Embodiment 3

[0037] A preparation method for cold-mixed cold paving asphalt mixture, comprising the following steps:

[0038] (1) Crush the granite into two kinds of stones with a particle size of 5-10mm and 2.3-5mm, and then weigh 7330kg of stones with a particle size of 5-10mm, 1800kg of stones with a particle size of 2.3-5mm, and a particle size of 0.1 - 300kg of 2.3mm quartz sand, 100kg of mineral powder ground into limestone with a particle size of less than 0.075mm, mixed evenly, dried to make the water content less than 15%, cooled to room temperature to obtain aggregate, and set aside;

[0039] (2) Heat 470kg of asphalt to 130-150°C;

[0040] (3) Add the additive to the asphalt and stir evenly;

[0041] Wherein, the addition amount of the additive is 12% of the asphalt addition amount; the additive is composed of the following components and the parts by weight of each component are: 20 parts of cyclobutane, 5 parts of polyethylene, 1 part of terpene resin, naphtha 74 copies;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com