Polyhydroxy amine oleate and preparing method thereof

A technology of polyhydroxy oleic acid and hydroxyalkyl tertiary amine, which is applied in the preparation of amino hydroxyl compounds, chemical instruments and methods, and the preparation of organic compounds, and can solve the problems of limited use, poor lubricity, stability, and corrosion resistance. , to achieve good water solubility and stability, low cost, and sufficient source of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

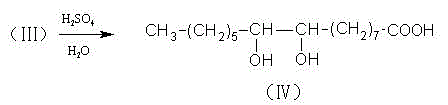

Method used

Image

Examples

Embodiment 1

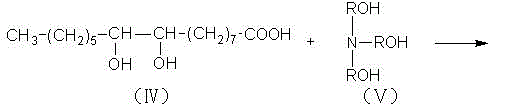

[0018] In a three-neck flask equipped with a stirring device, a reflux condensing device and a thermometer, add 80 grams of oleic acid, slowly add a mixture of 11 grams of acetic acid, 40 grams of hydrogen peroxide and 1.5 grams of concentrated sulfuric acid catalyst, and keep it at 80 ° C ~ 90 ° C Under temperature, carry out epoxidation reaction 2~3 hours, generate epoxidized oleic acid, stop reaction, reactant material is placed in the hot water of 4~5 times of volume and carry out hydrolysis, liquid separation, wash product with warm water, take oil layer, To obtain the hydrolyzed product dihydroxyoleic acid; add 15 grams of water, 70 grams of dihydroxyoleic acid and 42.5 grams of hydroxyisopropyl tertiary amine into a three-necked flask, and react at 40 ° C to 60 ° C for 1 to 2 hours to form an intermediate product Dihydroxy oleic acid hydroxyisopropyl tertiary amine salt, then add 100 grams of water-carrying xylene into the three-necked bottle, add 3 grams of 80% sulfuric...

Embodiment 2

[0020] In a three-neck flask equipped with a stirring device, a reflux condensing device and a thermometer, add 75 grams of oleic acid, slowly add a mixture of 10 grams of acetic acid, 38 grams of hydrogen peroxide and 2 grams of concentrated sulfuric acid catalyst, and keep it at 80 ° C ~ 90 ° C Under temperature, carry out epoxidation reaction 3~4 hours, generate epoxidized oleic acid, stop reaction, reactant material is placed in the hot water of 4~5 times of volume and carry out hydrolysis, separate liquid, wash product with warm water, take oil layer, To obtain the hydrolyzed product dihydroxyoleic acid; add 12 grams of water, 65 grams of dihydroxyoleic acid and 46 grams of triethanolamine to a three-necked flask, and react at 40°C to 60°C for 1 to 2 hours, and the intermediate product dihydroxyoleic acid produced Triethanolamine salt, then add 80 grams of water-carrying agent xylene to the three-necked bottle, add 3 grams of phosphoric acid, and carry out reflux esterific...

Embodiment 3

[0022] In a three-neck flask equipped with a stirring device, a reflux condensing device and a thermometer, add 70 grams of oleic acid, slowly add a mixture of 8 grams of acetic acid, 35 grams of hydrogen peroxide and 1 gram of concentrated sulfuric acid catalyst, and keep it at 80 ° C ~ 90 ° C Under temperature, carry out epoxidation reaction 2~4 hours, generate epoxidized oleic acid, stop reaction, reactant material is placed in the hot water of 4~5 times of volume and carry out hydrolysis, separate liquid, wash product with warm water, take oil layer, To obtain the hydrolyzed product dihydroxy oleic acid; add 10 grams of water, 60 grams of dihydroxy oleic acid and 56.5 grams of triisopropyl tertiary amine alkanolamine to a three-necked flask, and react at 40°C to 60°C for 1 to 2 hours, and the resulting The intermediate product dihydroxy oleic acid triethanolamine salt, then add 70 grams of xylene with water agent to the three-necked bottle, add 2.5 grams of 80% sulfuric aci...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap