An intumescent fire-resistant waterproof membrane and its preparation method

A waterproofing membrane and fire-resisting technology, applied in the field of expansion fire-resisting waterproofing membrane and its preparation, can solve the problems of structural failure, spread, and lack of preventing the continued spread of combustion, so as to delay failure, increase disaster reduction, and facilitate acceptance. and promotion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

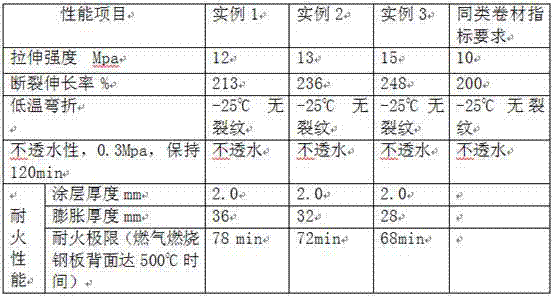

Examples

Embodiment 1

[0027] (1) Functional materials, the preparation process is: according to the mass parts, add 15 parts of melamine, 10 parts of pentaerythritol, 10 parts of ammonium polyphosphate, 10 parts of aluminum hydroxide, 10 parts of magnesium hydroxide, chopped 5 parts of rock wool fiber, start high-speed mixing for 3 minutes, add 2 parts of A-172 silane, stir for 5 minutes, and discharge to obtain functional materials;

[0028] (2) Mixed ingredients, the preparation process is: according to the mass parts, add 80 parts of chlorinated polyvinyl chloride resin, 8 parts of vinyl chloride resin, 4 parts of composite stabilizer, 1 part of polyethylene wax, and 30 parts of high chlorinated paraffin , 5 parts of acrylic ester copolymers, blended at high speed for 5 minutes, then added the prepared functional material, and mixed for 15 minutes to obtain a mixed powder;

[0029] (3) The prepared powder is processed by twin-screw plasticizing hot-melt, plasticizing, extruding and calendering f...

Embodiment 2

[0031] (1) Functional materials, the preparation process is: according to the mass parts, add 10 parts of melamine, 8 parts of pentaerythritol, 8 parts of ammonium polyphosphate, 10 parts of aluminum hydroxide, 10 parts of magnesium hydroxide, chopped 5 parts of rock wool fiber, start high-speed mixing for 3 minutes, add 2 parts of A-172 silane, stir for 5 minutes and discharge to obtain functional material;

[0032] (2) Mixed ingredients, the preparation process is: according to the mass parts, add 80 parts of chlorinated polyvinyl chloride resin, 8 parts of vinyl chloride resin, 4 parts of composite stabilizer, 1 part of polyethylene wax, and 30 parts of high chlorinated paraffin , 5 parts of acrylic ester copolymers, blended at high speed for 5 minutes, then added the prepared functional material, and mixed for 15 minutes to obtain a mixed powder;

[0033] (3) The prepared powder is processed by twin-screw heat melting, plasticization, extrusion and calendering to prepare e...

Embodiment 3

[0035](1) Functional materials, the preparation process is: according to the mass parts, add 10 parts of melamine, 6 parts of pentaerythritol, 6 parts of ammonium polyphosphate, 8 parts of aluminum hydroxide, 8 parts of magnesium hydroxide, chopped For rock wool fiber 5, start high-speed mixing for 3 minutes, add 2 parts of A-172 silane, stir for 5 minutes, and discharge to obtain functional materials;

[0036] (2) Mixed ingredients, the preparation process is: according to the mass parts, add 100 parts of chlorinated polyvinyl chloride resin, 10 parts of vinyl chloride resin, 6 parts of composite stabilizer, 1 part of polyethylene wax, and 35 parts of high chlorinated paraffin 10 parts of acrylate copolymer, blended at high speed for 5 minutes, then added the prepared functional material, and mixed for 15 minutes to obtain a mixed powder;

[0037] (3) The mixed powder is prepared by twin-screw heat-melting, plasticizing, extrusion and calendering molding processes to prepare ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com