Water-based environment-friendly multi-purpose ink

A multi-purpose, environmentally friendly technology, applied in ink, applications, household appliances, etc., can solve problems such as difficult to meet printing requirements, achieve the effects of reducing inventory and residual ink, avoiding toxic and harmful gas emissions, and improving gloss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

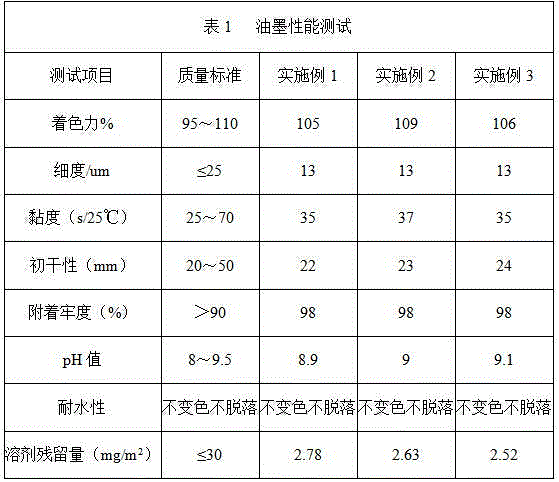

Examples

Embodiment 1

[0030] A kind of water-based ink, is made from the raw material of following parts by weight:

[0031] 34 parts of modified acrylic resin,

[0032] 20 parts of triethanolamine,

[0033] 16 parts of water-based paint,

[0034] 10 parts ethanol

[0035] Phosphate 1.8 parts,

[0036] 0.2 parts of silicone oil,

[0037] 20 parts of deionized water.

Embodiment 2

[0039] A kind of water-based ink, is made from the raw material of following parts by weight:

[0040] 30 parts of modified acrylic resin,

[0041] 18 parts of triethanolamine,

[0042] 19 parts of water-based paint,

[0043] 10 parts ethanol

[0044] Phosphate 2.1 parts,

[0045] 0.3 parts of silicone oil,

[0046] 20.6 parts of deionized water.

Embodiment 3

[0048] A kind of water-based ink, is made from the raw material of following parts by weight:

[0049] 27 parts of modified acrylic resin,

[0050] 16 parts of triethanolamine,

[0051] 22 parts of water-based paint,

[0052] 9 parts ethanol

[0053] Phosphate 2.5 parts,

[0054] 0.4 parts of silicone oil,

[0055] 23.1 parts of deionized water.

[0056] According to the ratio of raw materials in the above three examples, first add deionized water and ethanol to the reaction kettle to mix, then add modified acrylic resin according to the ratio, stir evenly, add triethanolamine, and keep the temperature at 175 ° C ~ 180 ° C Stir for 1 hour to 3 hours; then cool down to 95°C to 105°C, add water-based pigments, phosphate ester and silicone oil, stir for 0.5-1 hour, cool, grind and filter to obtain water-based environmentally friendly multi-purpose ink.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com