Pre-oxidation furnace

A technology of pre-oxidation furnace and furnace body, which is applied to the chemical characteristics of fibers, textiles and papermaking, etc., can solve the problems of decreased mechanical properties of carbon fibers, low mechanical properties of carbon fibers, and poor sealing performance of the oxidation furnace, and achieves improved tensile properties, The effect of uniform pre-oxidation and reduction of mechanical friction damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

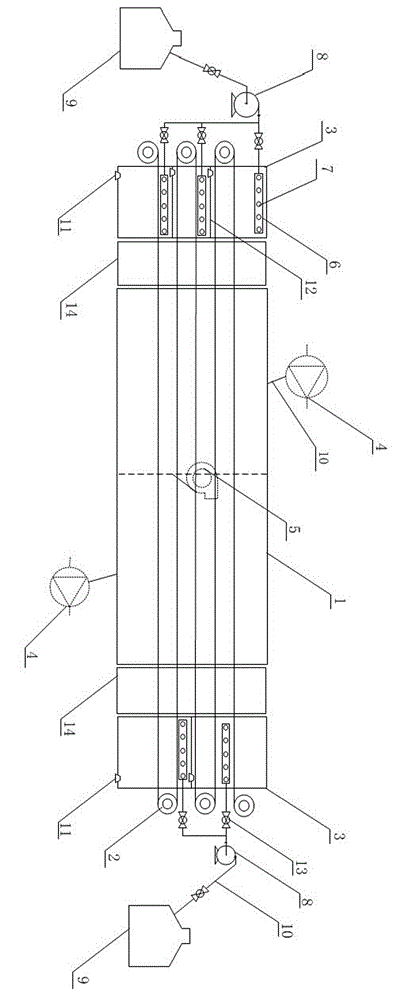

[0024] Such as figure 1 As shown, a pre-oxidation furnace includes a furnace body shell 1, a roller 2 and two furnace end humidifying devices 3, the furnace end humidifying devices 3 are located at both ends of the furnace body shell 1, and the furnace end humidifying device 3 is provided with a humidifying tube 6 for humidifying The pipe 6 is provided with a humidifying hole 7, and the humidifying pipe 6 is connected with the pipeline pump 8 through the connecting pipe 10, and the pipeline pump 8 is connected with the humidification liquid storage tank 9 through the connecting pipe 10, and the connecting pipe 10 is provided with a switching valve 13.

[0025] When in use, the humidifying pipe 6 is located above each layer of tow through the spray humidification method, and the humidifying liquid sprays and humidifies the fibers from top to bottom through the humidifying holes 7 .

[0026] The humidification tubes 6 are separated by partitions 12 , and the bottom of the partit...

Embodiment 2

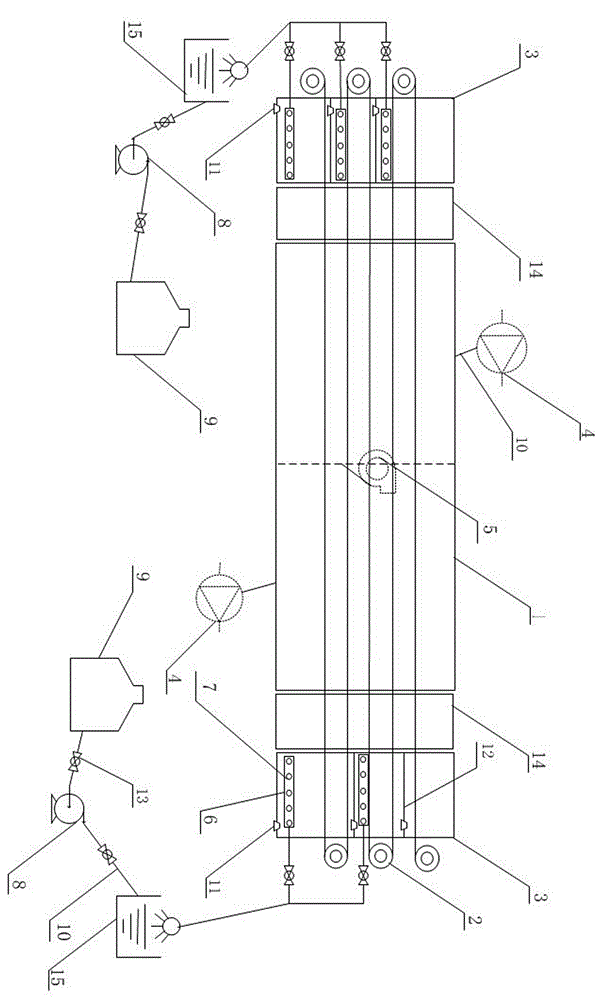

[0030] Such as figure 2 As shown, a pre-oxidation furnace includes a furnace body shell 1, a roller 2 and two furnace end humidifying devices 3, the furnace end humidifying devices 3 are located at both ends of the furnace body shell 1, and the furnace end humidifying device 3 is provided with a humidifying tube 6 for humidifying The tube 6 is provided with a humidifying hole 7, the humidifying tube 6 is connected to the ultrasonic nebulizer 15 through the connecting pipeline 10, the ultrasonic nebulizer 15 is connected to the pipeline pump 8 through the connecting pipeline 10, and the pipeline pump 8 is connected to the humidifying liquid storage through the connecting pipeline 10. Tank 9 is connected.

[0031] A partition 12 is arranged between each humidifying tube, and a waste liquid discharge port 11 is provided at the bottom of the partition 12 and the furnace end humidifier 3 , and the residual humidifying liquid can be gradually discharged through the waste liquid dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com