A rapid alkali-free scouring, bleaching, cleaning, dyeing and finishing process for cotton knitting

A cotton knitting and fast technology, applied in the field of dyeing and finishing, can solve the problems of equipment, labor, time, energy waste, etc., achieve good wetting and emulsifying properties, reduce waste water pollution, and reduce damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] 1. Fabric: 20STK double yarn + 40STK / 1 double sided fabric

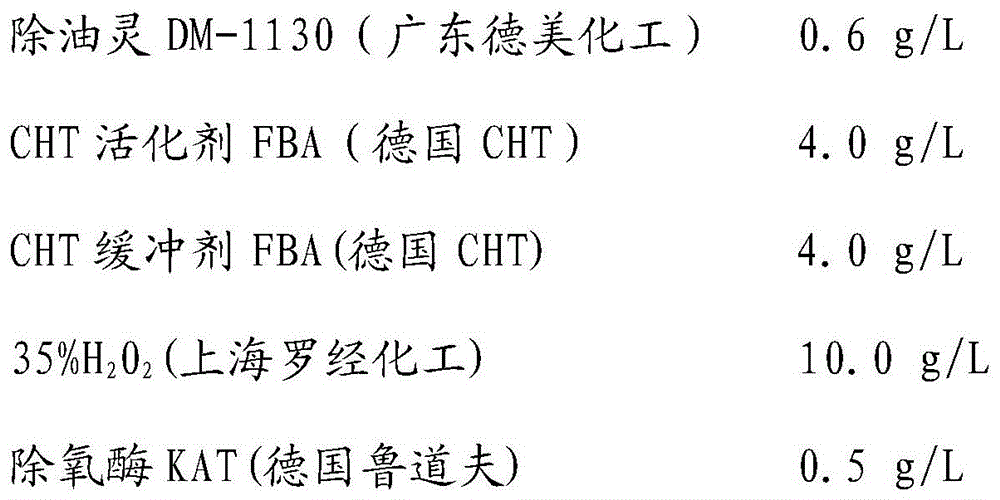

[0052] 2. Formula and conditions of rapid non-alkali scouring and bleaching process:

[0053]

[0054] A. The bath ratio of scouring and bleaching: 1:10, set the water level into the cloth. Add 0.6g / L of Deyouling DM-1130, 4.0g / L of CHT activator FBA and CHT buffer FBA respectively at room temperature, first pour into the auxiliary tank and stir evenly, then add slowly;

[0055] B. High temperature scouring and bleaching: run for 6 minutes after adding the additives used, slowly add 35% hydrogen peroxide 10.0g / L, run for 3 minutes at 2°C per minute to 90°C, keep warm for 40 minutes, and cool to 70°C at 3°C per minute, direct drainage;

[0056] C. Deoxygenation: Warm up to 40°C, add 0.5g / L deoxygenase KAT, keep warm for 10 minutes, drain directly after keeping warm, wash once, and dye;

[0057] D. Precautions: The same amount of CHT activator FBA and CHT buffer FBA can be used in the bleaching bath to a...

Embodiment 2

[0065] 1. Fabric: 32STK / 1SZ+10S / C right twill non-pull fleece

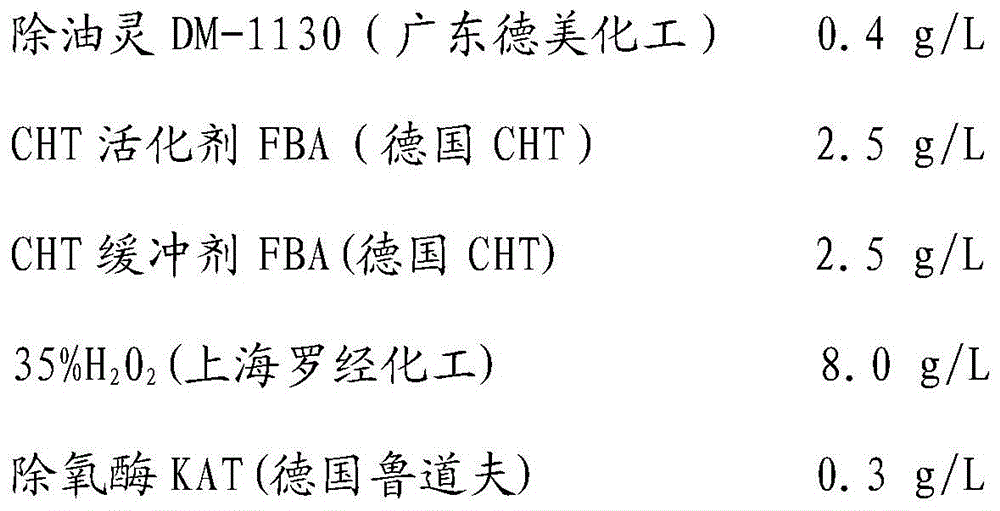

[0066] 2. Formula and conditions of rapid non-alkali scouring and bleaching process:

[0067]

[0068] A. The bath ratio of scouring and bleaching: 1:15, set the water level into the cloth. Add 0.4g / L of Deyouling DM-1130, 2.5g / L of CHT activator FBA and CHT buffer FBA respectively at room temperature, first pour into the auxiliary tank and stir evenly, then add slowly;

[0069] B. High temperature scouring and bleaching: run for 6 minutes after adding the additives used, slowly add 35% hydrogen peroxide 8.0g / L, run for 3 minutes at 2°C per minute to 90°C, keep warm for 30 minutes, and cool to 70°C at 3°C per minute, direct drainage;

[0070] C. Deoxygenation: Warm up to 40°C, add 0.3g / L deoxygenase KAT, keep warm for 10 minutes, drain directly after keeping warm, wash once, and dye;

[0071] D. Precautions: The same amount of CHT activator FBA and CHT buffer FBA can be used in the bleaching bath to achiev...

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com