Double-tube jet flow uniform steam injection technology for horizontal well and assorted tool

A horizontal well and steam injection technology, which is applied in the direction of production fluid, wellbore/well components, earthwork drilling and production, etc. It can solve the problems of not having double-pipe steam injection, small amount of gas injection, uneven steam injection, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

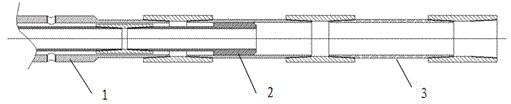

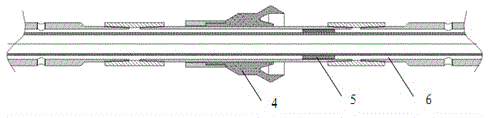

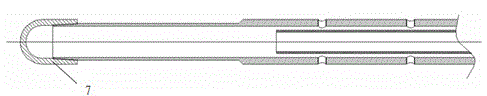

[0016] A horizontal well double-pipe jet uniform steam injection process and supporting tools, including a pipe string and a tubing nipple, characterized in that: the pipe string is located at the lower end of the steam injection packer; the pipe string is divided into variable density steam injection Jet pipe 1 and steam injection flushing pipe 6, variable density steam injection jet pipe 1 and steam injection flushing pipe 6 are connected through steam injection distributor 2; steam injection nozzle 8 is installed on the variable density steam injection jet pipe 1; A high-temperature leather cup packer 4 is arranged on the outer periphery of the variable density steam injection jet pipe 1; a high temperature centralizer 5 is installed between the variable density steam injection jet pipe 1 and the steam injection flushing pipe 6; the variable density steam injection jet pipe 1 is provided with a plug 7 at the port. The cross-sectional shape of the steam injection nozzle 8 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com