Blockage remover for decompression and steam injection in high clay content sandstone oil reservoir

A technology for sandstone reservoirs with high clay content, applied in the field of depressurization steam injection plugging agent for sandstone reservoirs with high clay content, it can solve the problem of unheated crude oil in the formation, poor acidification treatment effect, block oil well To solve problems such as low production capacity, achieve the effect of improving the effect of steam stimulation, realize the efficient development of blocks, and improve the quality of steam injection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

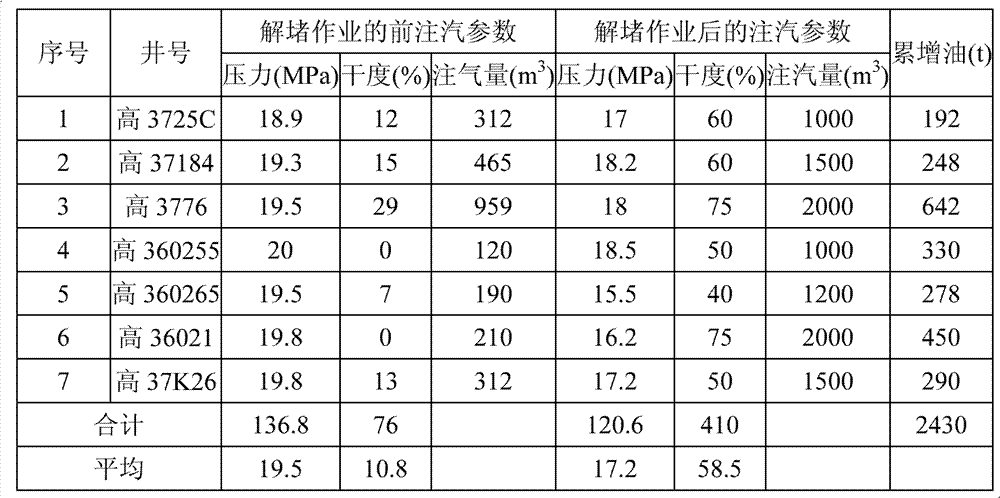

Examples

Embodiment

[0040] This example provides a plugging remover for depressurizing steam injection in sandstone reservoirs with high clay content, which is composed of an organic plugging remover and an inorganic plugging dissolving agent, wherein,

[0041] Based on the total weight of the organic block remover, it has the following composition: alkylphenol ethoxylates, 0.5%, sodium lauryl sulfate, 0.5%, dodecylsulfonic acid, 0.5%, sodium silicate , 1.5%, sodium benzoate, 0.3%, Sp169, 0.3%, sodium phosphate, 0.3%, polydimethyldiallylammonium chloride, 1%, the rest is water;

[0042] The main inorganic blockage dissolution agent is composed of the pre-pretreatment liquid and the main body dissolution blockage depressurization increase injection liquid, the mass ratio of the two is 1:2;

[0043] Based on the total weight of the pre-pretreatment liquid, it has the following composition: hydrochloric acid, 10.0%, clay stabilizer, 1.0%, alkylphenol polyoxyethylene ether, 0.5%, corrosion inhibitor,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com