Electrically all-insulated pneumatic motor based on high-strength composite engineering plastic

A technology of engineering plastics and air motors, applied in the direction of machines/engines, non-variable engines, mechanical equipment, etc., can solve the problems of personal safety threats to electrical equipment safety workers, air motors have no electrical insulation function, etc., and achieve high power , High degree of self-lubrication, the effect of protecting personal safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings.

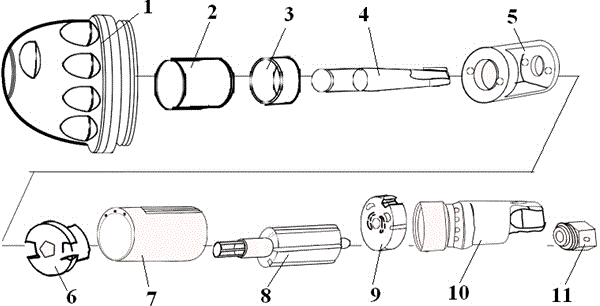

[0016] Such as figure 1 As shown, an electrically fully insulated air motor based on high-strength composite engineering plastics is characterized in that it includes a front hammer sleeve 1, a bushing 2, a spacer 3, a hammer shaft 4, a hammer guardrail 5, a cam hammer 6, and a cylinder Cylinder 7, rotor 8, cylinder outer cylinder 9, outer shell 10, air inlet 11; the front hammer sleeve 1, bushing 2, spacer 3, hammer shaft 4, hammer guardrail 5, cam hammer 6, cylinder barrel 7. The rotor 8, the cylinder outer cylinder 9, and the outer shell 10 are connected in sequence; the front hammer sleeve and the outer shell form a complete air motor shell, and the bushing 2, the spacer 3, the hammer shaft 4, and the hammer guardrail 5 , cam hammer 6, cylinder barrel 7, rotor 8, and cylinder outer barrel 9 are wrapped in the accommodating cavity; The material of the front hammer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com