Method for preventing heat injury of dosing module, controller and urea exhaust purification system

A purification system and thermal damage technology, which is applied to the electronic control of exhaust treatment devices, exhaust treatment, exhaust devices, etc., can solve the problems of increased risk of thermal damage to distribution modules and lack of cooling water.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

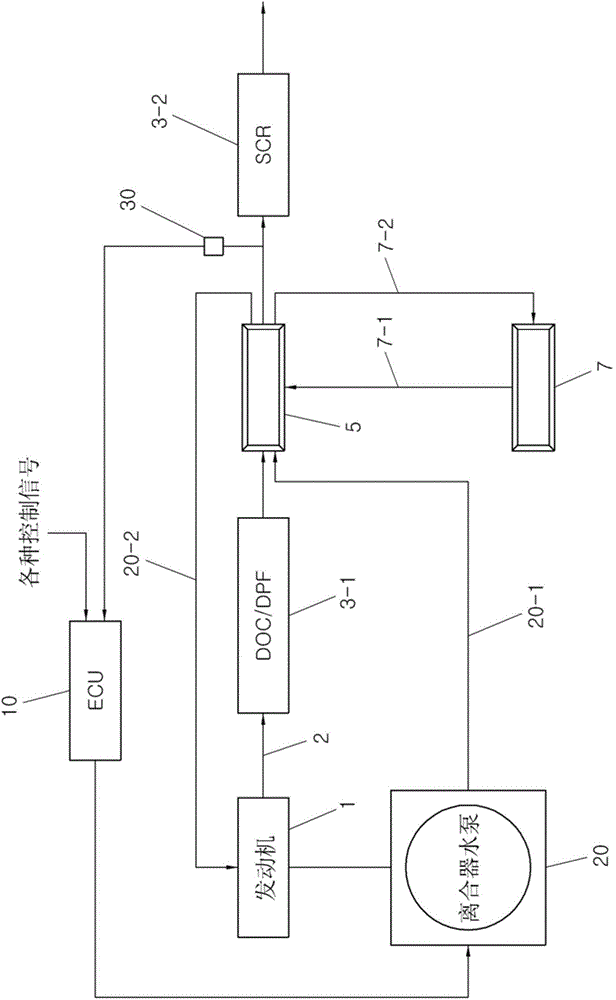

[0034] Hereinafter, a vehicle control system and an operating method thereof according to an embodiment of the present invention will be described with reference to the accompanying drawings. Elements are conceptually shown in the accompanying drawings to describe the concept of the present invention, and descriptions of known elements among the elements are omitted.

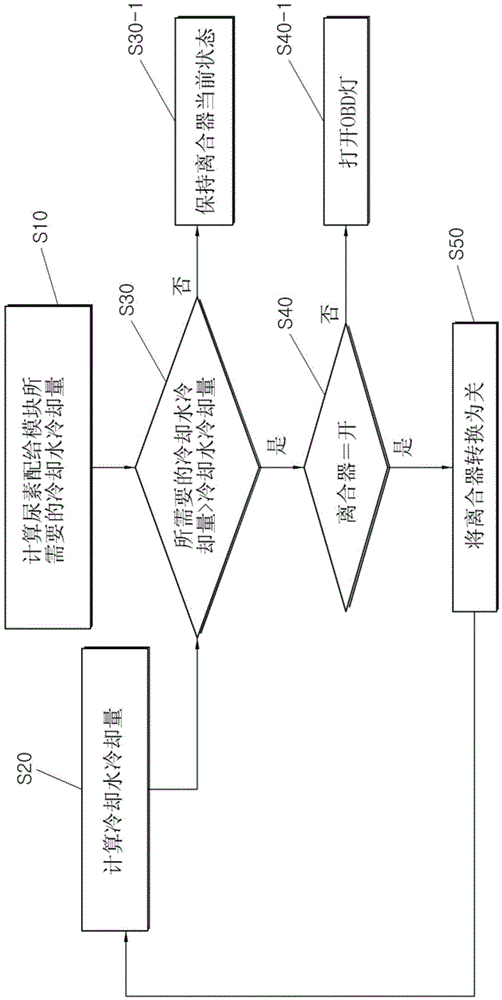

[0035] figure 1 An operational flow for preventing thermal damage to a distribution module according to an embodiment of the present invention is shown. A case in which urea is used as a reducing agent will be described below.

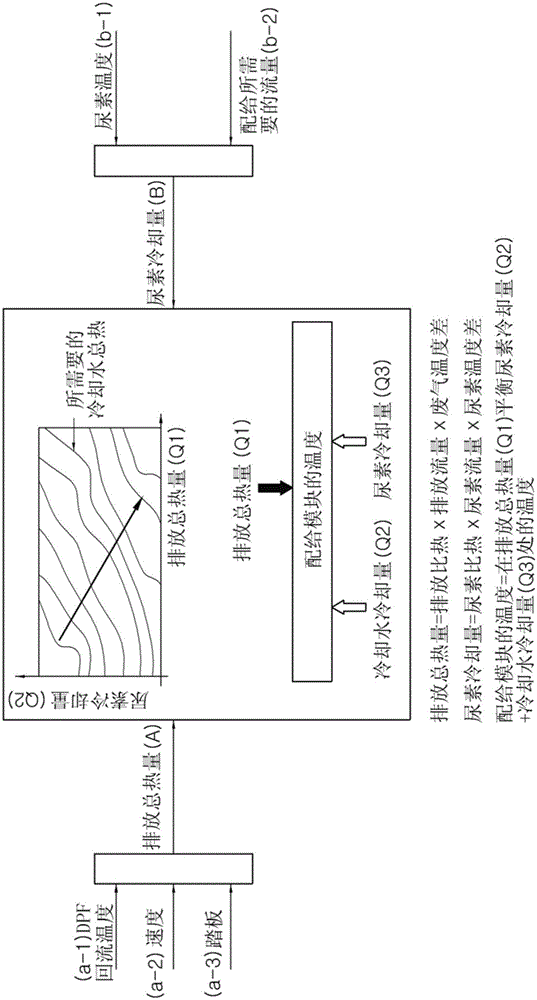

[0036] Such as figure 1 As shown, by determining the required cooling water cooling capacity of S10 and determining the cooling capacity of the engine cooling water of S20 when the required cooling water cooling capacity in S30>the cooling capacity of the engine cooling water, and by as in S50 A logic circuit for preventing thermal damage of the distribution module is implemented by f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com