Hinging type hydraulic pipe joint

A hydraulic pipe joint, articulated technology, applied in the direction of pipe/pipe joint/pipe fitting, elbow, siphon, etc., can solve the problem that the installation space pipe joint is difficult to meet the requirements, and achieves the elimination of matrix thread failure, small size and reliable sealing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

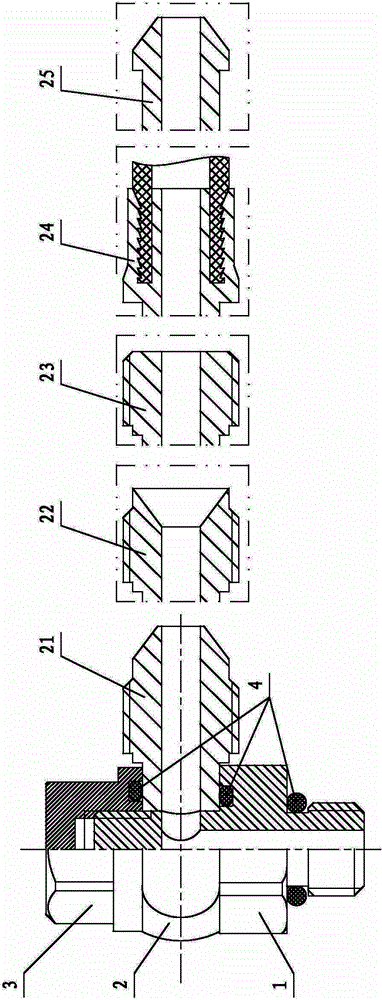

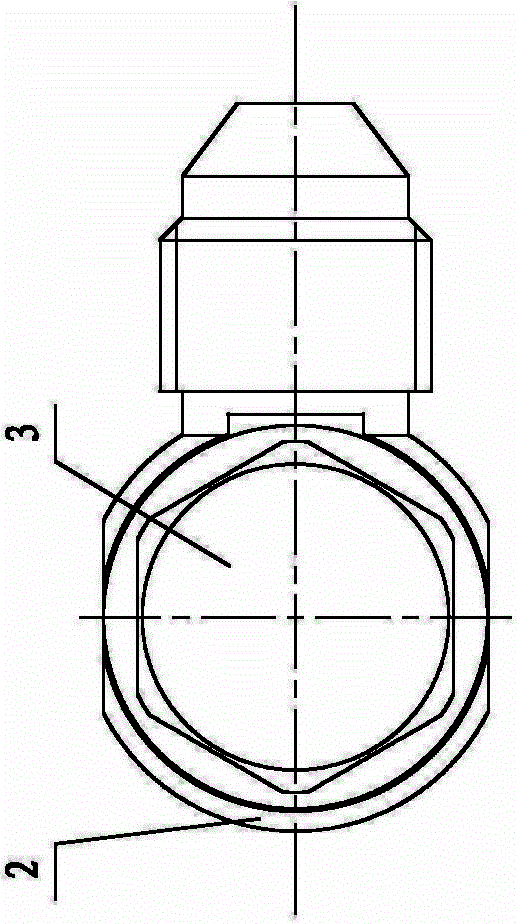

[0029] Such as figure 1 , figure 2 and Figure 6 As shown, the articulated pipe joint fixing base 1 of this embodiment is an ordinary articulated pipe joint fixing base 11, that is, one end of the ordinary articulated pipe joint fixing base 11 is threadedly connected to the substrate, and can be connected with the threaded hole of the substrate. Matching, thread optional models are pipe thread, M thread, pipe thread is preferred; the other end of the ordinary articulated pipe joint fixing base 11 is provided with an external thread (thread Optional models include pipe thread and M thread, pipe thread is preferred); there is a gap 14 between the other end of the common articulated pipe joint fixing base 11 and the articulated pipe joint lock nut 3 . Ordinary articulated pipe joint fixing base 11 is respectively provided with accommodation on the end surface in contact with articulated pipe joint steering joint 2 and the end surface of articulated pipe joint locking nut 3 in ...

Embodiment 2

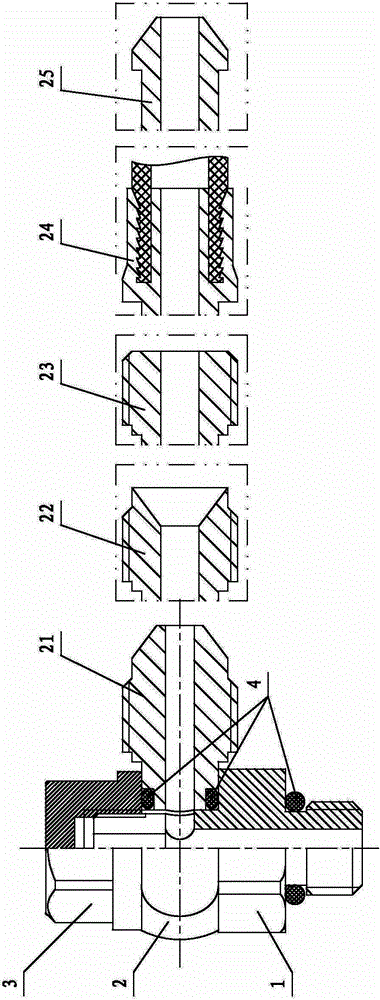

[0036] In order to meet the needs of installing data lines or other linear items inside the pipe joint, the hinged pipe joint fixing base 1 of this embodiment is a wire-type hinged pipe joint fixing base 12, such as image 3 , Figure 4 , Figure 5 and Figure 7 As shown, one end of the threaded hinged pipe joint fixing base 12 is threadedly connected to the substrate, which can be matched with the threaded hole of the substrate. The available thread types include pipe thread and M thread, and pipe thread is preferred; The other end of the articulated pipe joint fixing base 12 is provided with an external thread that is threadedly connected with the articulated pipe joint lock nut 3 (thread optional models include pipe thread and M thread, pipe thread is preferred); There is a gap 14 between the other end of the fixed base 12 of the type pipe joint and the locking nut 3 of the hinged pipe joint. The end face of the articulated pipe joint adjustment joint 2 in contact with t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap