A planetary roller screw and method for uniform load distribution thereof

A planetary roller and screw technology, which is applied to transmissions, belts/chains/gears, mechanical equipment, etc., can solve the problems of demanding space and output force, small lead, and the end of meshing threads falling off.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

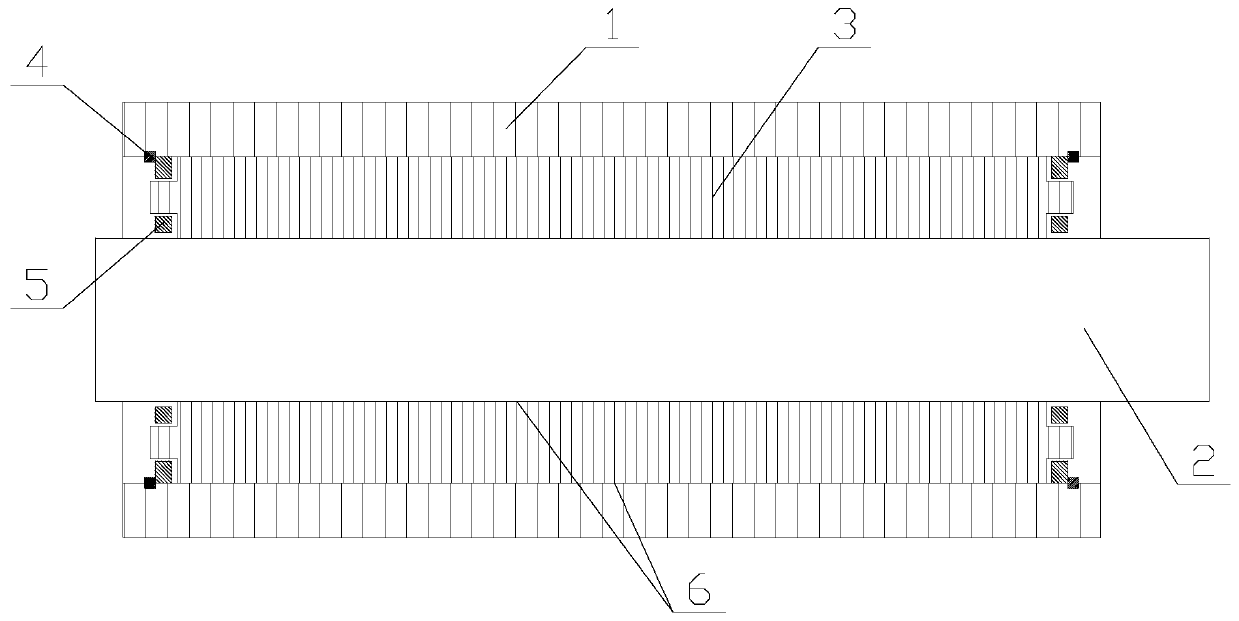

[0037] Such as figure 1 , Figure 6 as well as Figure 7 As shown, a planetary roller screw provided in this embodiment includes a screw 2, a nut 1, two retaining rings 4, two cages 5 and more than three rollers 3, and the screw 2 is located at Inside the nut 1 and coaxially arranged with the nut 1 , more than three rollers 3 are located between the screw 2 and the nut 1 and rotate relative to the screw 2 and the nut 1 . A retaining ring 4 and a cage 5 are located at the left end of the roller 3 , and another retaining ring 4 and another cage 5 are located at the right end of the roller 3 .

[0038] Part or all of the threads on the inner surface of the nut 1 or in the meshing area on the outer surface of the screw are correction threads 10. The correction thread 10 refers to a thread whose pitch and pitch have been corrected. The correction thread The correction value of the thread pitch of the thread 10 is positively related to the load borne by the correction thread 10 ...

Embodiment 2

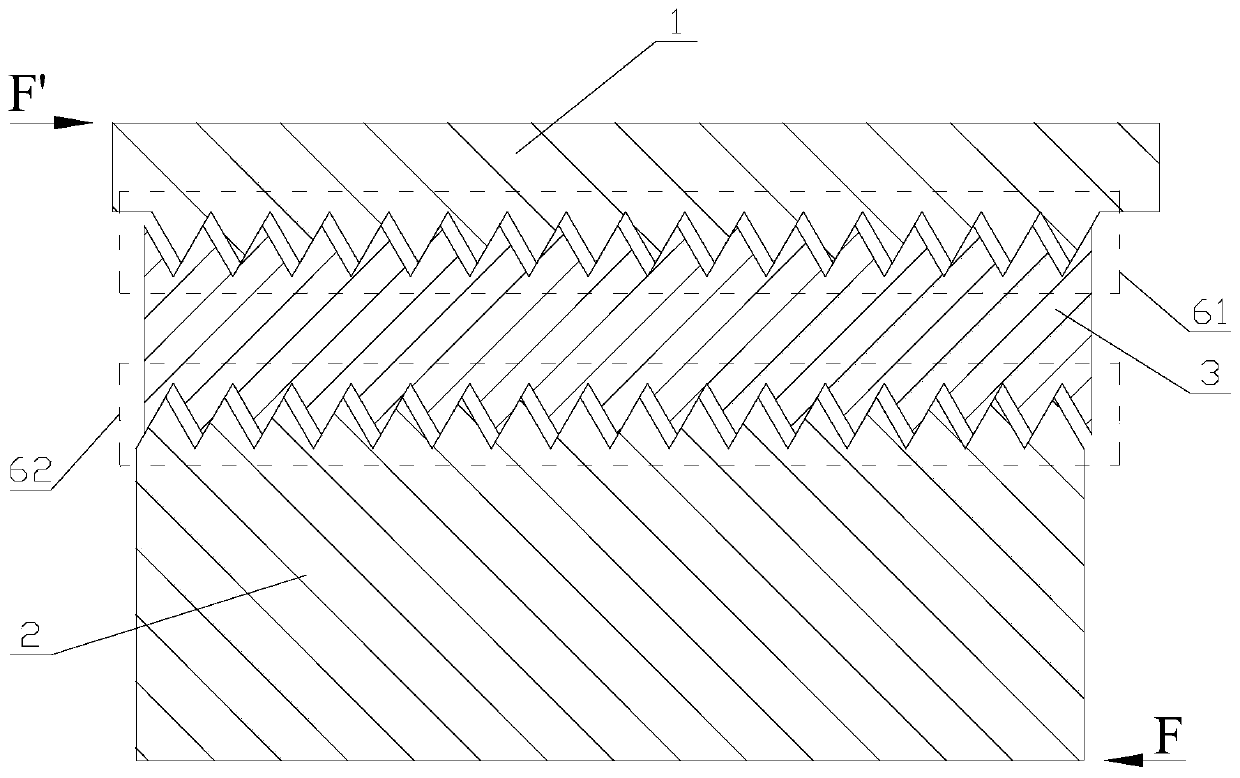

[0045] Such as figure 1 , Figure 6 and Figure 7As shown, a load uniform distribution method for the planetary roller screw in Embodiment 1 provided in this embodiment, there are two meshing regions 6 on the planetary ball screw, and the load uniform distribution method is implemented as follows:

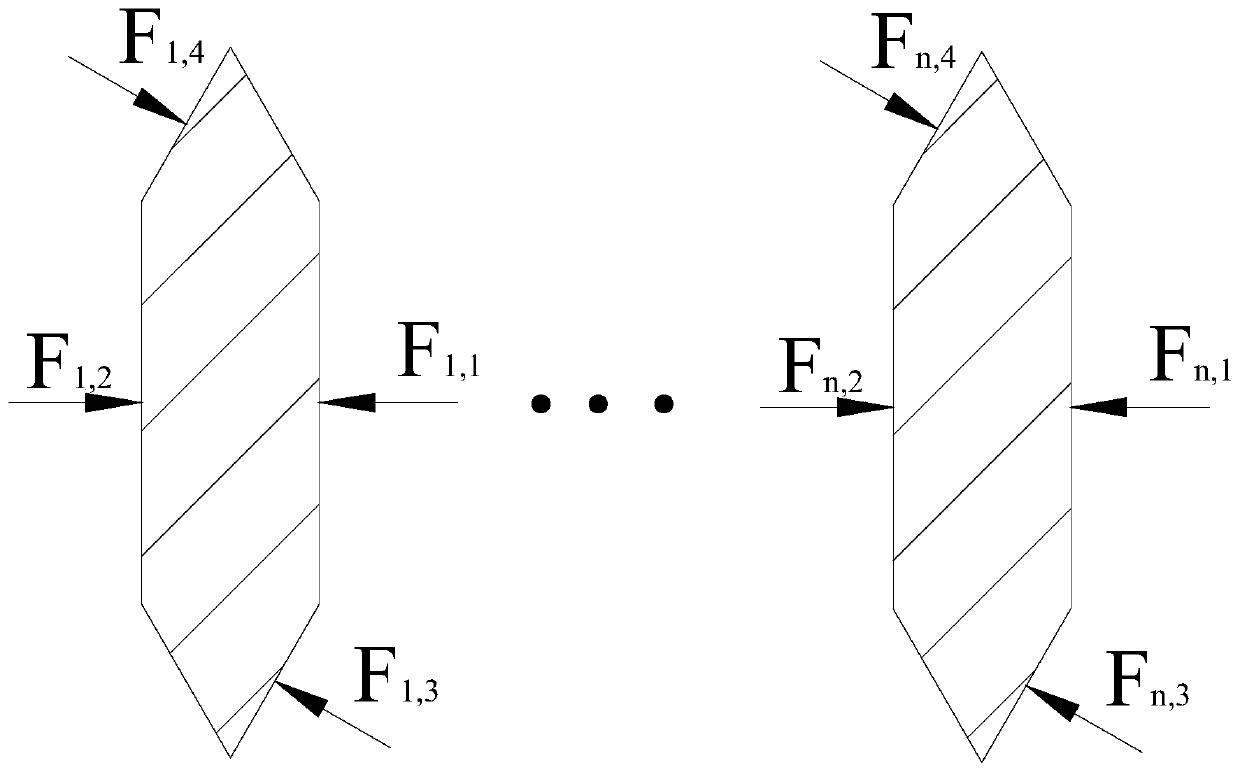

[0046] The pitches of some or all of the threads in the meshing region 6 are corrected according to the load borne by each thread in the meshing region 6 to obtain the corrected thread 10 .

[0047] Usually, only the thread pitch of some of the threads at both ends of the meshing area 6 is corrected, because according to the results of finite element analysis or actual calculation, it can be seen that the loads on the threads at both ends of the meshing area 6 are much greater than those at the middle of the meshing area 6. The load on the thread.

[0048] After the thread pitch is corrected, when the nut 1 and the screw 2 mesh, the thread teeth in the middle of the meshing are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com