Power cable spacing clamp

A technology of power cables and spacers, which is applied in the direction of pipe supports, pipes/pipe joints/fittings, mechanical equipment, etc., can solve problems that affect the safe and stable operation of power cables, affect the current carrying capacity of power cables, and cannot perform power outage rectification, etc., to achieve Easy to install and implement, simple to operate, and improve the effect of isolation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with accompanying drawing:

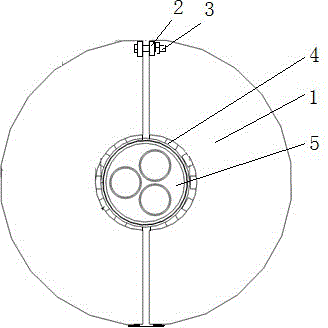

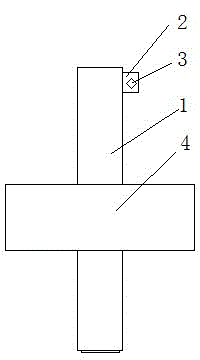

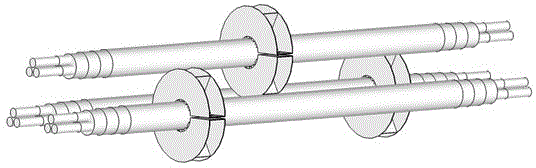

[0014] As shown in the figure, a power cable interval clamp is characterized in that two pieces of insulating material are combined to form an annular spacer 1, the inner wall of the annular spacer 1 is provided with anti-slip teeth, and one end of the two spacers 1 The outer wall is connected by a soft sheet, and the other end is provided with a corresponding connecting lug 2. The connecting lug 2 is provided with a connecting hole, and the bolt 3 passes through the connecting hole to connect with the nut. The two spacers 1 The inner wall of the inner wall is respectively provided with a semicircular sleeve 4, the inner end surface of the sleeve 4 is provided with anti-slip teeth, the spacer 1 and the sleeve 4 are in a cross vertical shape, and the spacer 1 is arranged in the middle of the sleeve 4 to To improve the isolation effect of the power cable 5, one end of the two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com