Gas filling apparatus and gas filling method

A filling device and filling method technology, applied in container filling methods, gas/liquid distribution and storage, gas processing applications, etc., can solve problems such as gas pressure rise and gas flow rate are too large

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Embodiments for implementing the present invention will be described in detail below with reference to the drawings.

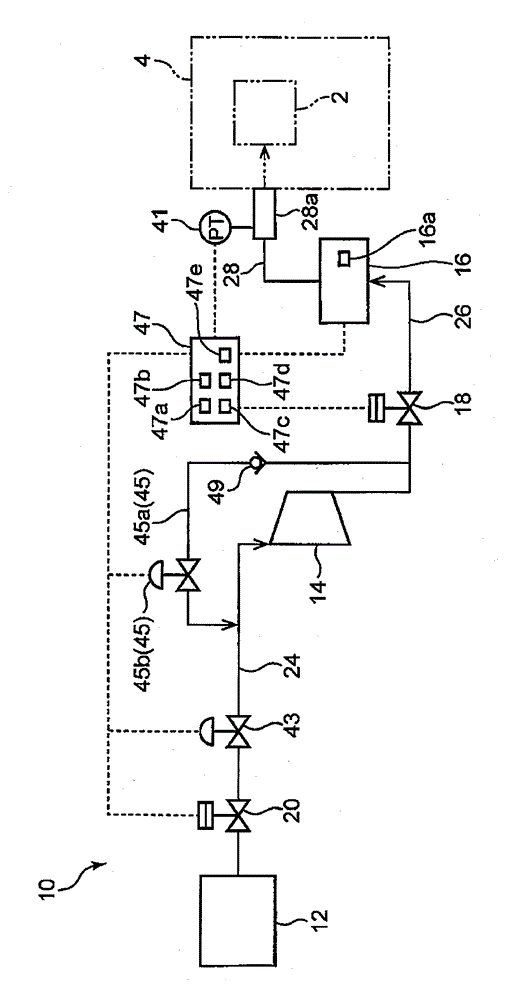

[0032] The gas filling device 10 of the present embodiment is a device for supplying hydrogen gas to the fuel cell vehicle 4, and is installed, for example, in a hydrogen station as a hydrogen gas supply station. The fuel cell vehicle 4 is an example of a tank-mounted device on which the gas tank 2 is mounted. .

[0033] The gas filling device 10 includes a pressure accumulator 12 for storing hydrogen, a compressor 14 for sucking the hydrogen in the pressure accumulator 12 and discharging the sucked hydrogen, and sending the hydrogen discharged from the compressor 14 to the gas tank 2. Distributor 16, a first on-off valve 18 as an on-off valve on the discharge side, and a second on-off valve 20 as an on-off valve on the suction side.

[0034] Hydrogen gas is stored at a predetermined pressure (for example, 40 MPa) in the accumulator 12 . One end of a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com