System and method for acquiring instrumentation and equipment information based on computer vision

A technology of computer vision and equipment information, applied in the direction of closed-circuit television system, comprehensive factory control, electrical program control, etc., can solve the problems of slow response speed, low degree of automation, high cost, etc., and achieve fast response speed, high degree of automation, and production low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

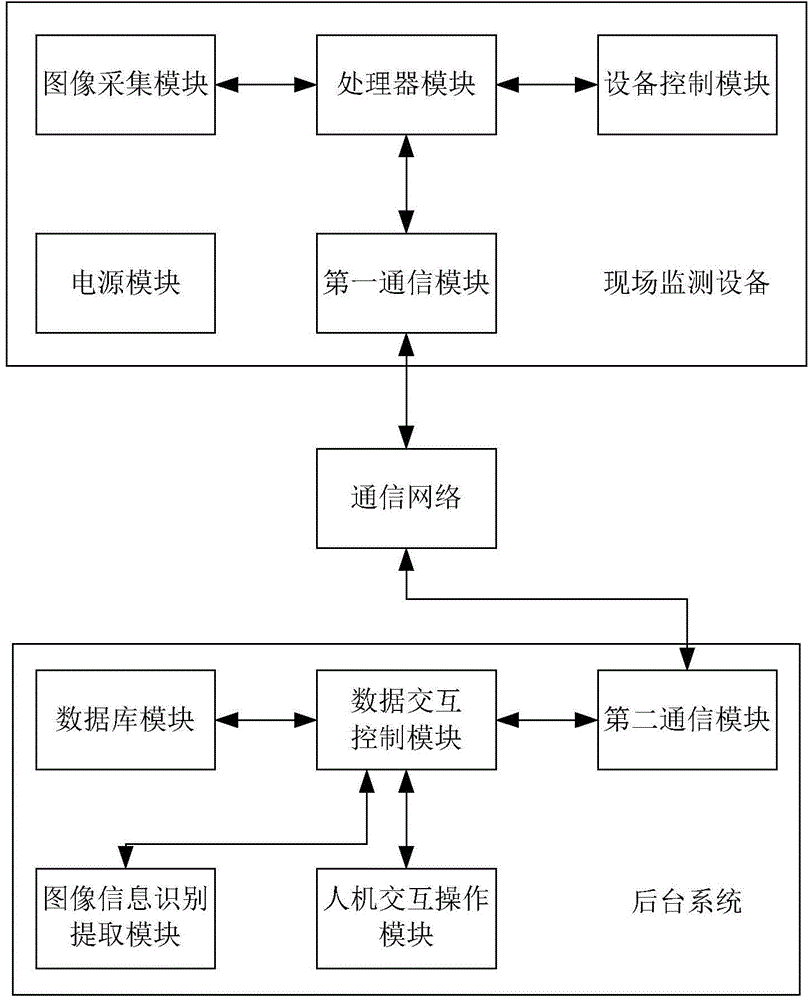

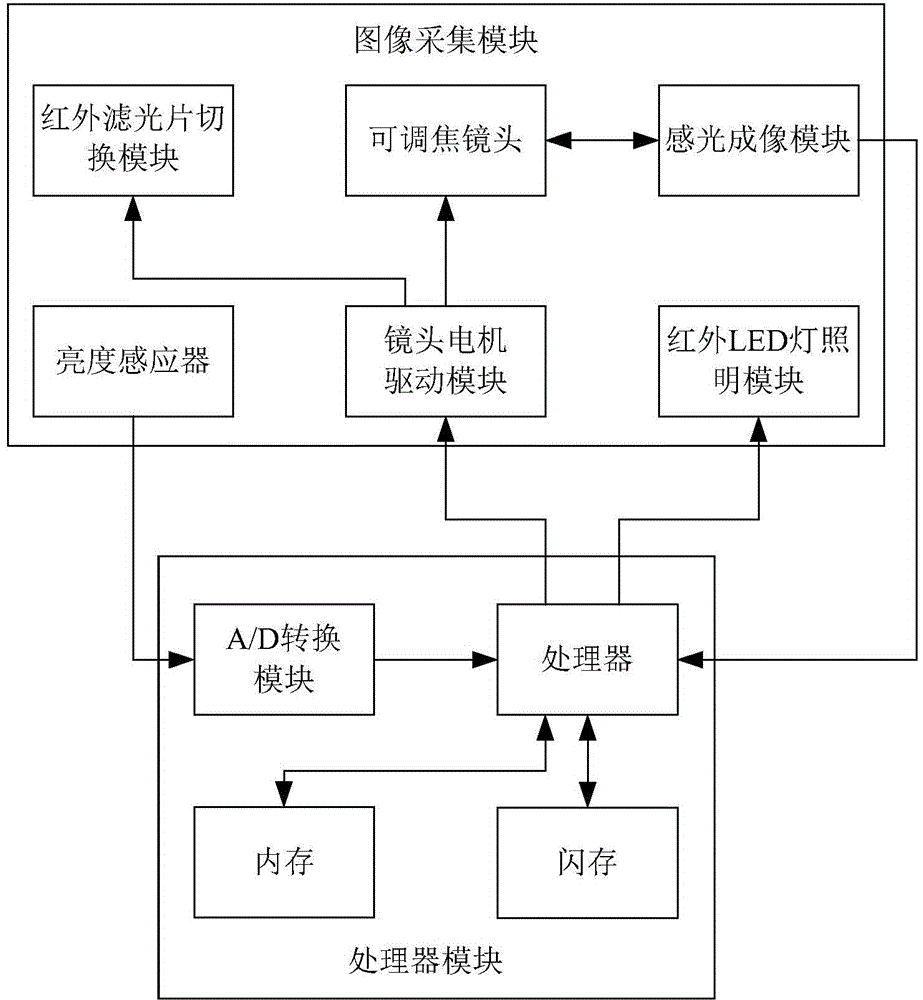

[0081] refer to figure 1 with figure 2 , a computer vision-based system for collecting information on instrumentation equipment, including on-site monitoring equipment, a communication network, and a background system. The on-site monitoring equipment includes an image acquisition module, a processor module, a first communication module, an equipment control module, and a The power module for power supply of the monitoring equipment, and the processor module are respectively connected with the image acquisition module, the equipment control module and the first communication module;

[0082] The background system includes a data interaction control module, an image information recognition and extraction module, a database module, a second communication module, and a human-computer interaction operation module. The interactive operation modules are connected, and the second communication module is connected with the first communication module through a communication network t...

Embodiment 2

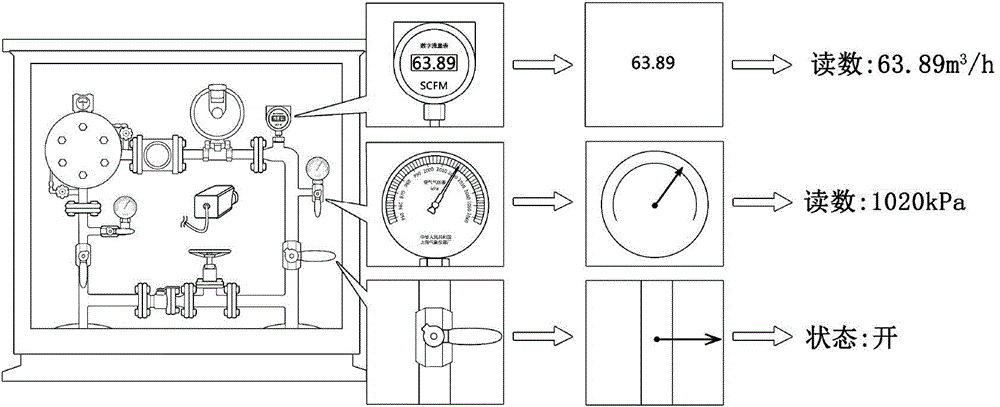

[0098] A computer vision-based method for collecting instrumentation equipment information using the system of Embodiment 1 includes:

[0099] S0. Install the image acquisition module of the on-site monitoring equipment to a position where a clear image of the instrument and equipment to be monitored can be collected;

[0100] S1. The background system obtains the preset acquisition parameter instructions input by the user to the human-computer interaction operation module and sends them to the on-site monitoring equipment;

[0101] S2. The on-site monitoring equipment calls the image acquisition module to acquire one or more images of the instrument equipment to be monitored according to the preset acquisition parameter instructions and sends them to the processor module;

[0102] S3, the processor module preprocesses the image collected by the image acquisition module, and judges whether to perform image information identification and extraction locally according to the loca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com