Circuit board and circuit board manufacturing method

A circuit board manufacturing and circuit board technology, applied in the directions of printed circuit manufacturing, printed circuits, printed circuit components, etc., can solve problems such as disconnection, depression of electrical connection pads, and disconnection, so as to avoid disconnection and reduce disconnection. The effect of the possibility of the line

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The circuit board and the manufacturing method of the circuit board provided by the technical solution will be further described in detail below with reference to the accompanying drawings and embodiments.

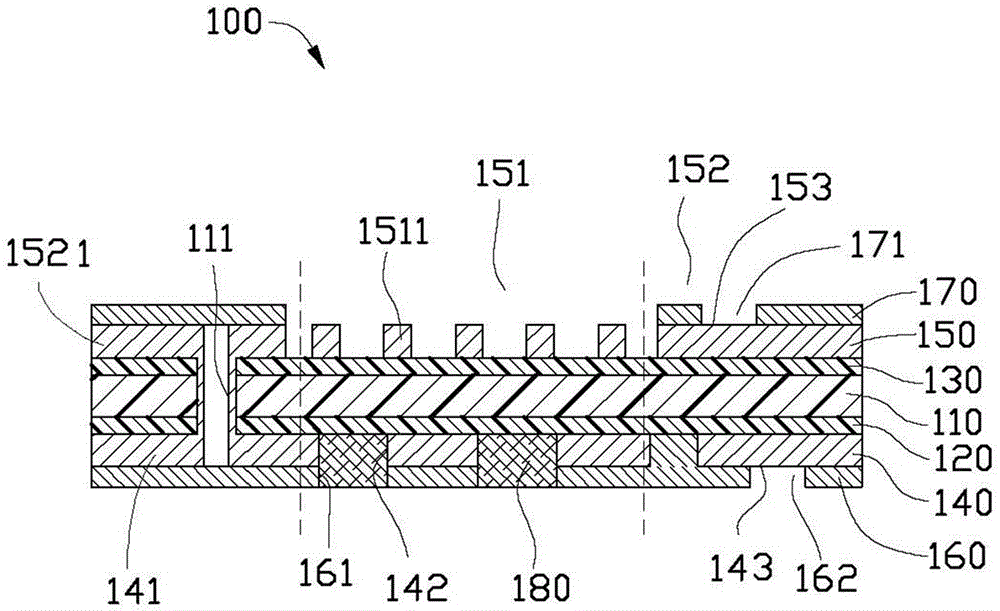

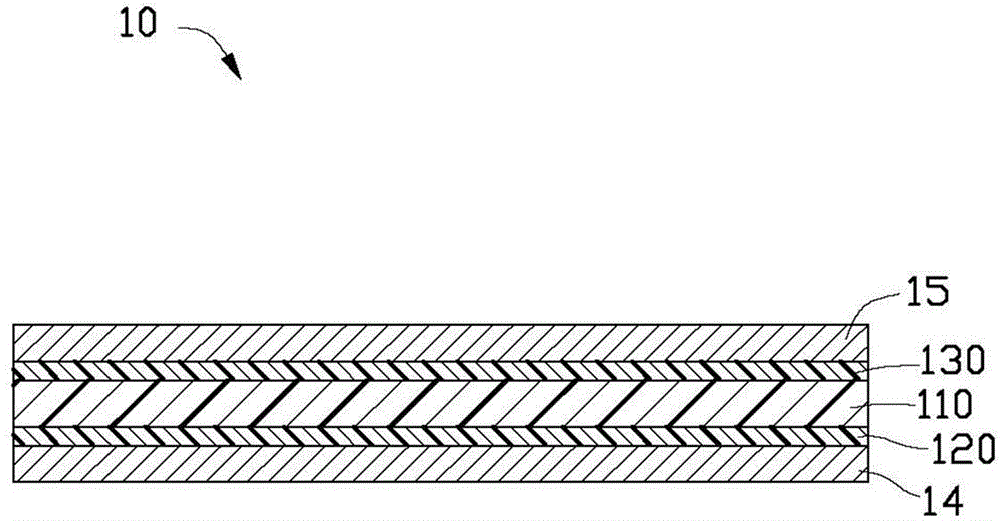

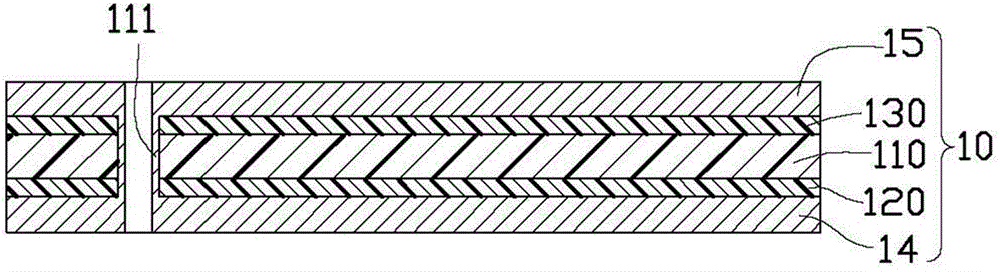

[0018] see figure 1 , the circuit board 100 provided by this technical solution includes a substrate 110 , a first adhesive layer 120 , a second adhesive layer 130 , a first conductive circuit layer 140 , a second conductive circuit layer 150 , a first cover film 160 , and a second cover film 170 And solder mask ink 180.

[0019] The substrate 110 includes a dielectric layer and an inner conductive circuit layer. The number of the dielectric layers is at least one. The number of the inner conductive circuit layers is one less than the number of dielectric layers. The dielectric layer and the inner conductive circuit layer are arranged at intervals. The adjacent inner conductive circuit layers are electrically connected through conductive holes in the dielectric ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com