Production technology of fully-quenched high-hardness scale gear

A production process and high-hardness technology, which is applied to the production process field of fully quenching high-hardness large-scale gears, can solve the problems of large heat treatment deformation, waste of materials, high cost, etc., so as to reduce welding labor intensity, improve production efficiency, and ensure stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] This embodiment provides a production process for fully quenching high-hardness scale gears, characterized in that the production process includes the following steps:

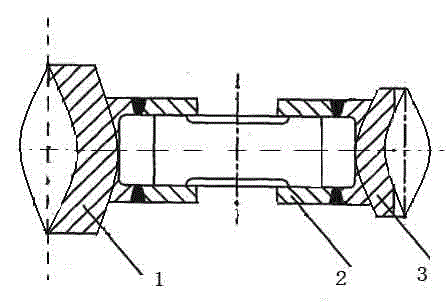

[0017] A. Select the materials of ring gear (1), wheel hub (2) and sub-plate (3) according to the needs of manufacturing scale gears;

[0018] B. Determine the basic process route for processing the ring gear (1), hub (2) and sub-plate (3), and process them separately:

[0019] a. Process the ring gear (1): select the ring gear forging, normalize after forging, rough turn the two ends of the ring gear and the inner and outer circles of the ring gear, and leave a margin of 12-15mm for the length and diameter of the ring gear. Chamfering on both sides of the outer circumference of the ring gear, then quenching and tempering treatment, and finally turning before welding, leaving a margin of 5-8mm for the length of both ends of the ring gear, and turning the inner circle to the required size before welding,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com