Meter Assembly Automatic Locking Screw Machine Nail Feeding Mechanism

A technology for automatically locking screw machines and electric meters, applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve problems affecting product quality, damage processing equipment, etc., and achieve the effect of avoiding product quality decline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

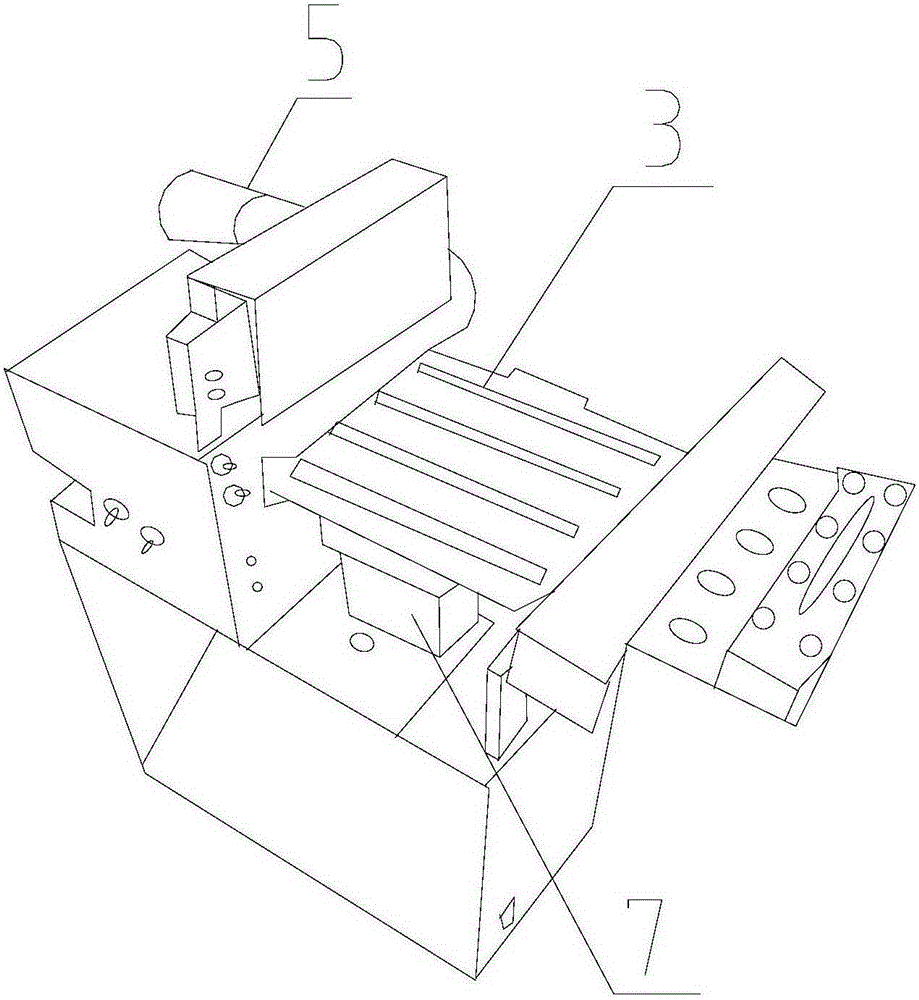

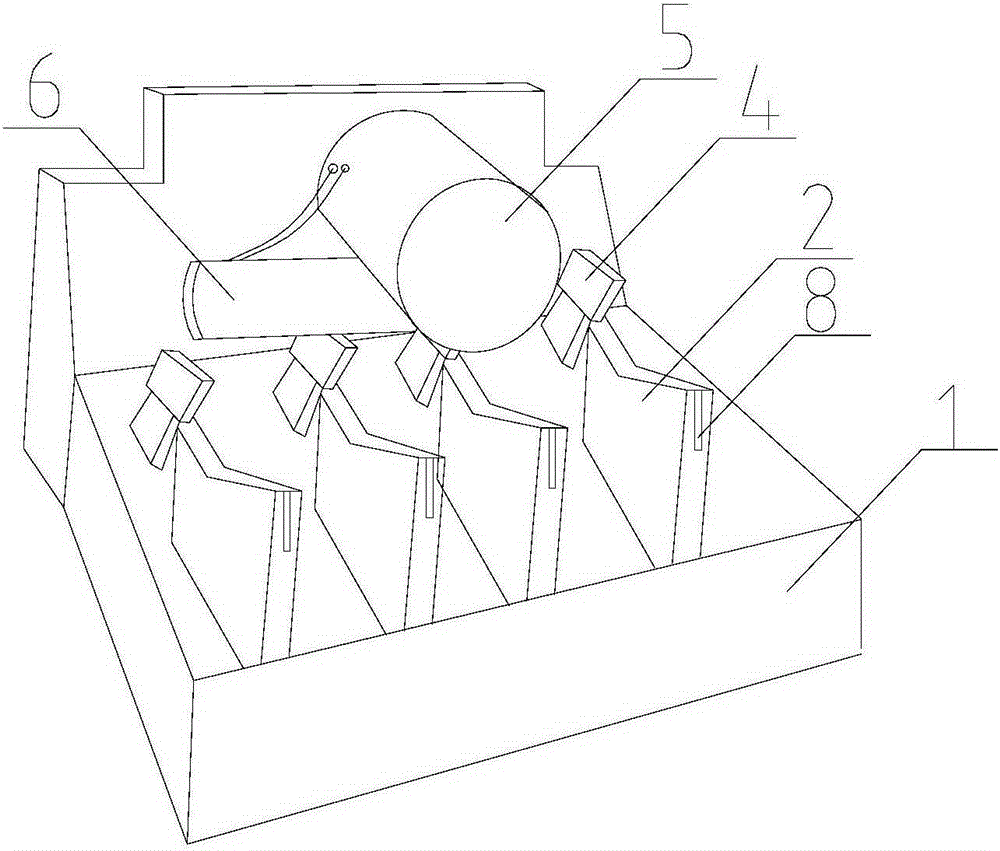

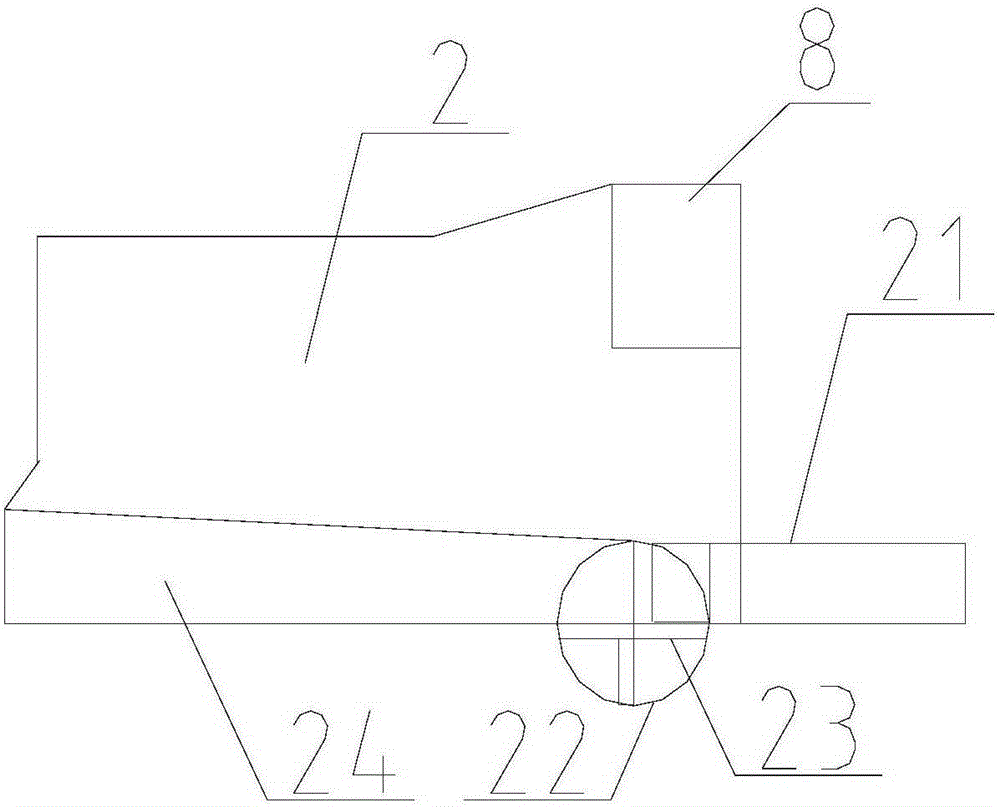

[0014] Such as figure 1 , figure 2 As shown, the nail feeding mechanism of the electric meter assembly automatic locking screw machine of the present invention is installed in the electric meter assembly automatic locking screw machine, and includes a screw compartment 1 in which four screw feeding channels are provided. Four screw feed channels are selected because traditional electric tools usually have 4 screws on one side. This is more convenient. Each channel is provided with a vertical screening device 2, and the end of the vertical screening device 2 is connected with a screw direct feeding channel 3, and the connection between the vertical screening device 2 and the screw direct feeding channel 3 is provided with a screening brush 4, and the screw is directly fed Channel 3 is connected to the corresponding electric screw batch. A motor 5 is provided, and the motor 5 is connected to the sorting gear box 6, and the sorting gear box 6 is connected to the vertical screeni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com