3D printer

A technology of 3D printers and printing devices, applied in the direction of additive processing, etc., which can solve the problems of inconvenient maintenance and maintenance, complex structure of printers, and large space occupied by installation and use, and achieve simple structure, easy assembly and maintenance, and improved portability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

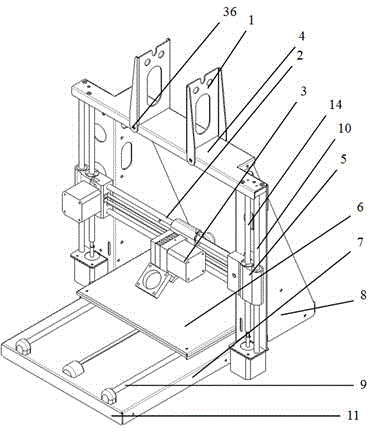

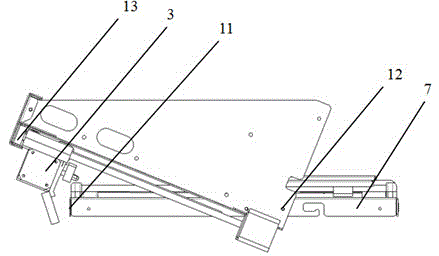

[0028] Such as figure 1 As shown, a 3D printer includes a printing device 3, a base plate 7 and an industrial control PLC. The two sides of the base plate 7 are provided with a gantry support 4 for installing the printing device 3, and the two sides of the gantry support 4 are The lower part of the pillar 8 is hinged with the base plate 7, and the base plate 7 is provided with a stage 6 for installing printed items.

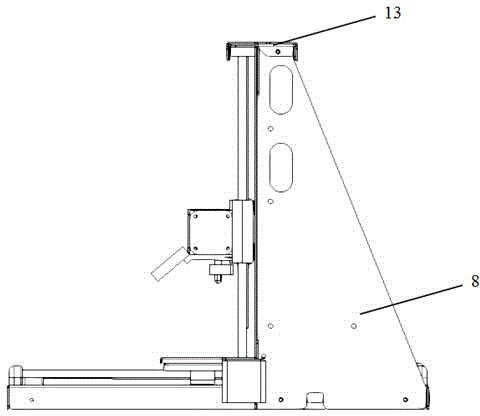

[0029] Such as Figure 4 As shown, the crossbeam 13 of the gantry support 4 is provided with a wire supply cylinder 31 and a bearing plate 35 for providing the printing raw material line to the printer, and two bearing plates 35 supporting the cylinder 31 are vertically arranged on both sides of the crossbeam 13. The lower parts of the bearing plates 35 are hinged with the beams 13 respectively.

[0030] The base plate 7 is provided with a Y-axis slide rail 9, and the object stage 6 is slidably connected to the Y-axis slide rail 9. The pillars 8 on both sides o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com