Detonator automatic chemical dispensing system

A technology of dispensing medicine and detonator

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solution of the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

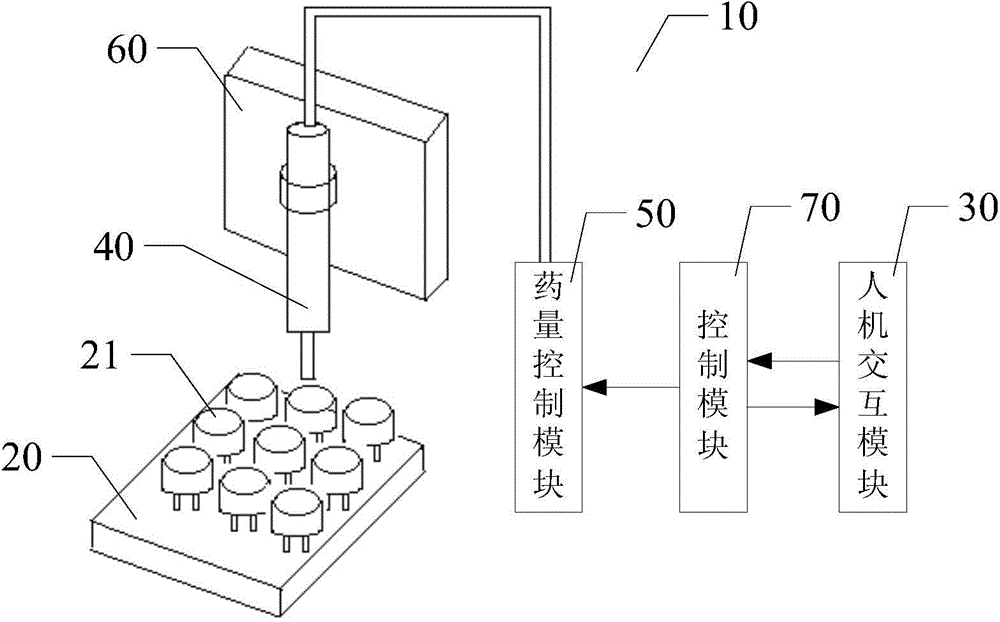

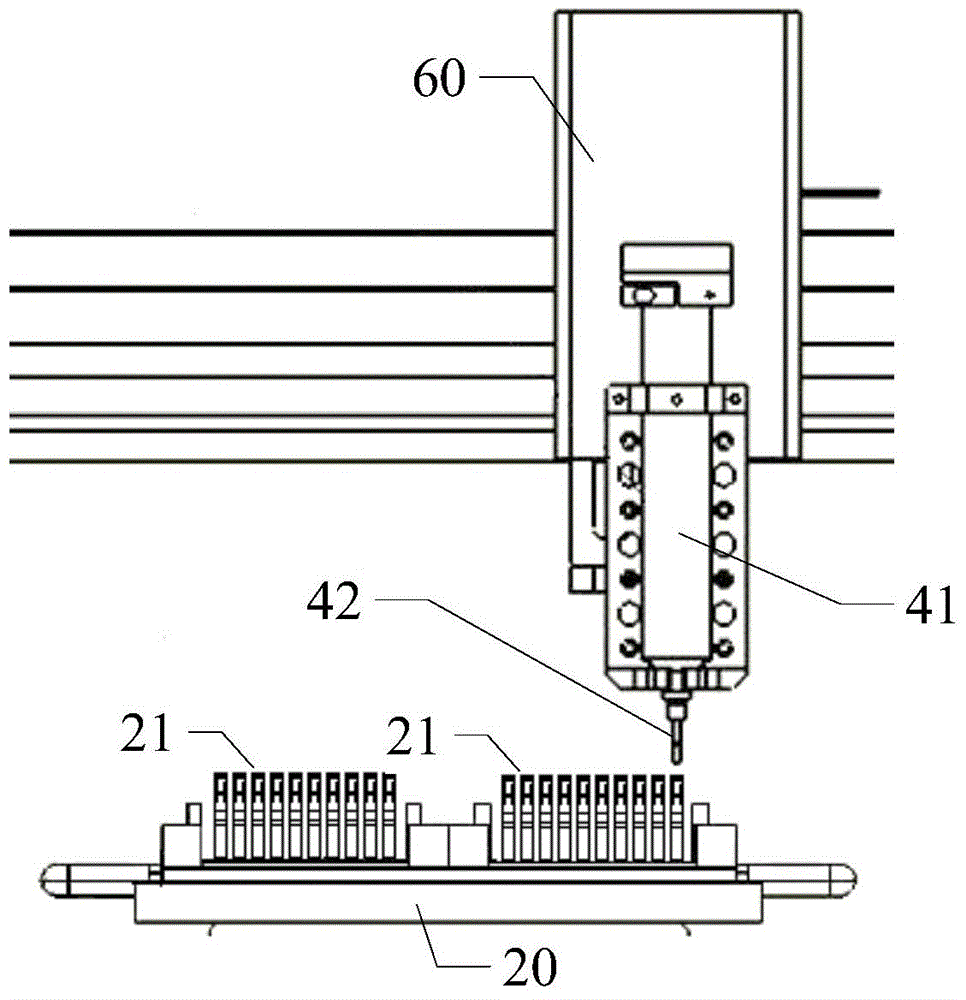

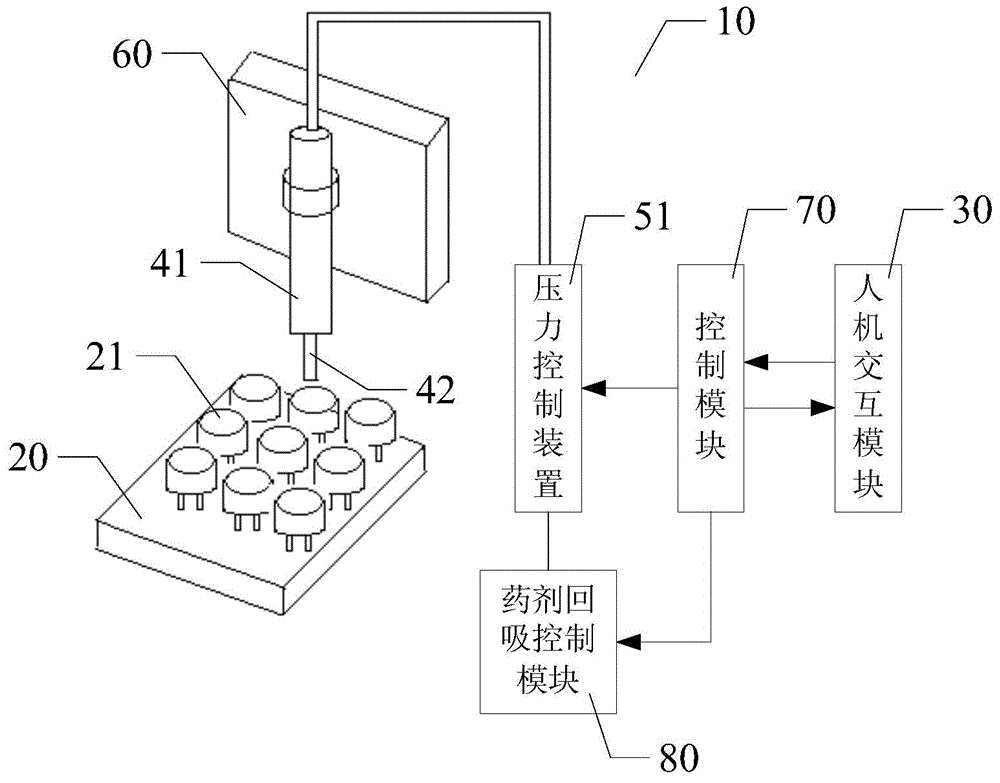

[0027] The present invention provides a detonator automatic dispensing system 10, see figure 1 and figure 2 As shown, the system includes: a workbench 20, which is used to fix the ignition part 21 of the detonator to be dispensed; a human-computer interaction module 30, which is used to set and display the working parameters and workflow of the dispenser system 10; one or more point The medicine module 40 is used for dispensing the detonator ignition part 21; the dose control module 50 is used for controlling the single dispensing dose of the dispensing module 40; the stepping module 60 is used for controlling the dispensing module 40 and the workbench The relative movement of 20 enables the dispensing module 40 to dispense medicine to the detonator ignition part 21; the control module 70 is used to control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com