Measuring device and method for initial velocity of gas gushing out from coal seam borehole

A gas gushing and measurement device technology, applied in the direction of measurement, drill pipe, drill pipe, etc., can solve the problems of difficult operation, safety threat, and influence on the accuracy of drilling gas, and achieve simple operation process, accurate and reliable measurement, avoid the effect of work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

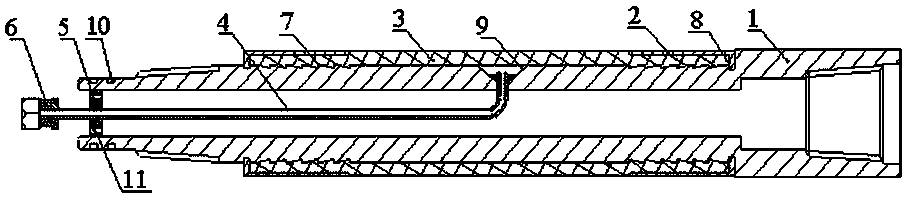

[0025] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , a coal seam drilling gas gushing initial velocity measuring device, mainly comprising a drill rod body 1 connected with a drill bit 15 with a pressure air outlet 16, characterized in that: wear-resistant capsule 3 is fixed on the drill rod body 1 by a wear-resistant capsule sleeve 2 , the wear-resistant capsule 3 on the drill pipe body 1 is provided with a through hole for sealing threads, and the sealing thread bolts fix the grouting pipe 4. The grouting pipe 4 is connected to the grouting pipe joint 6 through the grouting pipe bracket 5 with the ventilation hole 11 .

[0026] Wherein: the wear-resistant capsule sleeve 2 is withheld on the taper groove 7 of the drill pipe through the withholding groove 8 .

[0027] Wherein: the wear-resistant capsule 3 on the drill rod body 1 is provided with a through hole of a conical sealing thread 9 .

[0028] Among them, the wear-resistant capsule 3 is made of fla...

Embodiment 2

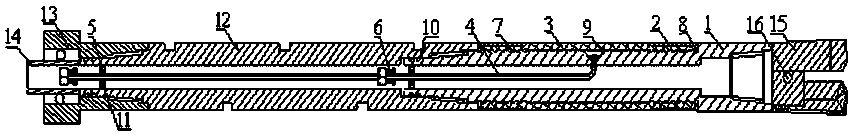

[0030] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , a coal seam drilling gas gushing initial velocity measuring device, mainly comprising a drill rod body 1 connected with a drill bit 15 with a pressure air outlet 16, characterized in that: wear-resistant capsule 3 is fixed on the drill rod body 1 by a wear-resistant capsule sleeve 2 , the wear-resistant capsule 3 on the drill pipe body 1 is provided with a through hole for sealing threads, and the sealing thread bolts fix the grouting pipe 4. The grouting pipe 4 is connected to the grouting pipe joint 6 through the grouting pipe bracket 5 with the ventilation hole 11 .

[0031] Wherein: the wear-resistant capsule sleeve 2 is withheld on the taper groove 7 of the drill pipe through the withholding groove 8 .

[0032] Wherein: the wear-resistant capsule 3 on the drill rod body 1 is provided with a through hole of a conical sealing thread 9 .

[0033] Wherein: the 1 end of the drill rod body with the O-rin...

Embodiment 3

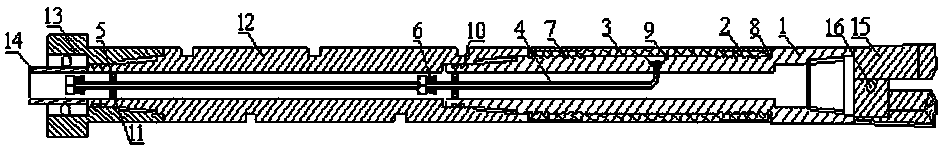

[0036] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , a coal seam drilling gas gushing initial velocity measuring device, mainly comprising a drill rod body 1 connected with a drill bit 15 with a pressure air outlet 16, characterized in that: wear-resistant capsule 3 is fixed on the drill rod body 1 by a wear-resistant capsule sleeve 2 , the wear-resistant capsule 3 on the drill pipe body 1 is provided with a through hole for sealing threads, and the sealing thread bolts fix the grouting pipe 4. The grouting pipe 4 is connected to the grouting pipe joint 6 through the grouting pipe bracket 5 with the ventilation hole 11 .

[0037] Wherein: the wear-resistant capsule sleeve 2 is withheld on the taper groove 7 of the drill pipe through the withholding groove 8 .

[0038] Wherein: the wear-resistant capsule 3 on the drill rod body 1 is provided with a through hole of a conical sealing thread 9 .

[0039] Among them: the 1 end of the drill pipe body with the O...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com