Rubber power vibration absorber

A dynamic vibration absorber and rubber technology, applied in non-rotational vibration suppression and other directions, can solve the problems of vibration-absorbing rubber deformation and tearing, potential safety hazards, rework and repair, etc., and achieve the effect of reducing vibration and noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

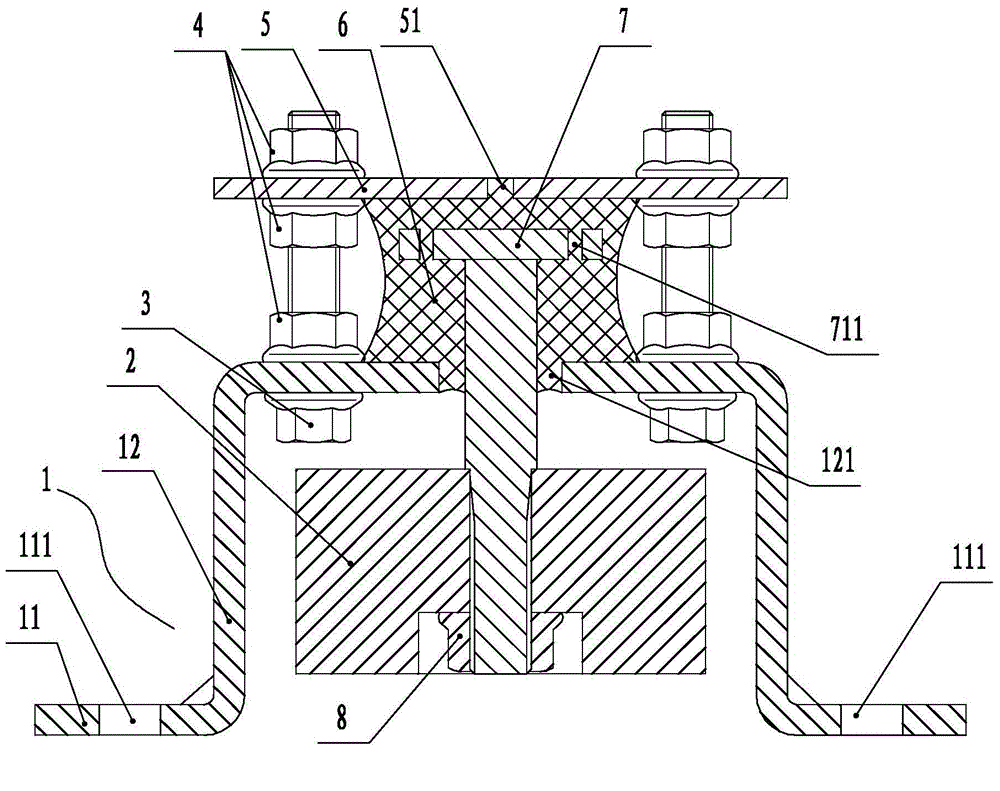

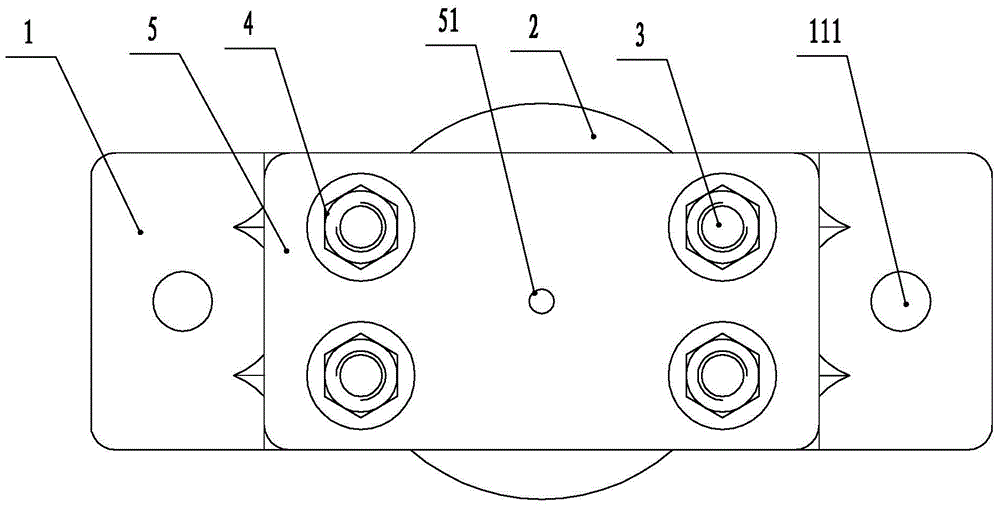

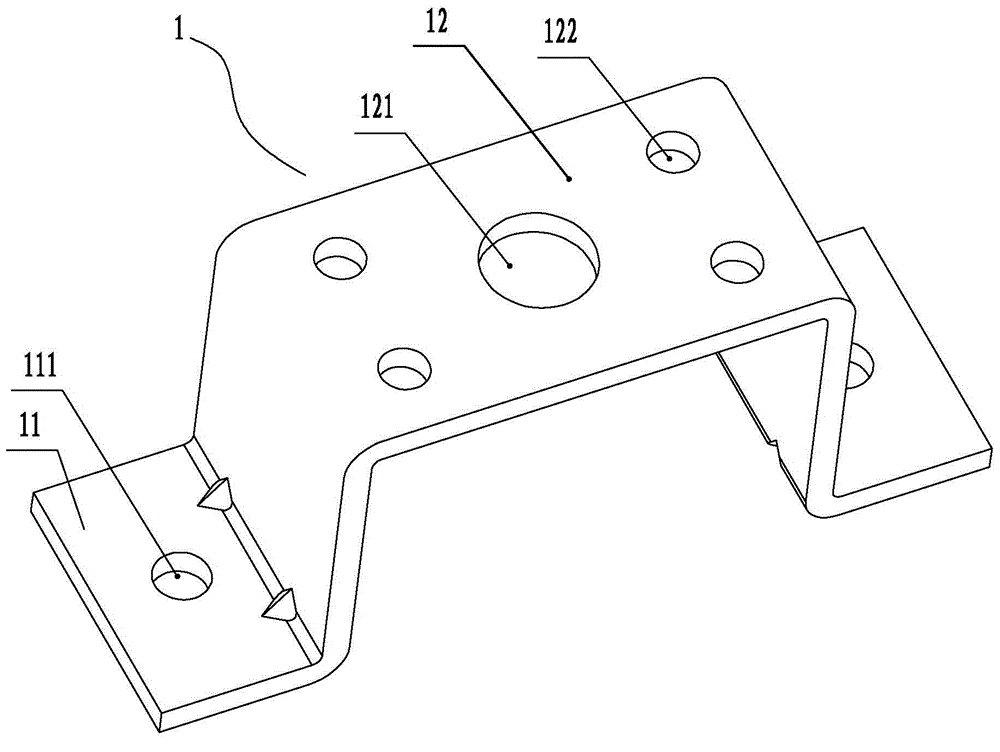

[0047] A rubber dynamic shock absorber, comprising a mounting bracket 1, a mass inertia block 2, an upper platen 5, a vibration-absorbing rubber 6, and a vibration support 7, wherein:

[0048] The mass inertia block 2 is located in the mounting bracket 1, the top of the vibrating bracket 7 is exposed outside the top of the mounting bracket 1, and the bottom end of the vibrating bracket 7 penetrates into the top of the mounting bracket 1 and is fixedly connected to the mass inertia block 2 Inside, the upper platen 5 is located above the top of the vibrating bracket 7, the upper platen 5, the mounting bracket 1, and the vibrating bracket 7 are connected together by thermal vulcanization of the vibration-absorbing rubber 6, and the cross-section of the vibration-absorbing rubber 6 is circular. It can also be square, rectangular or rhombus.

[0049] The top of the mounting bracket 1 and the upper platen 5 are also connected by adjusting fasteners around the vibration-absorbing rub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com