A flange connection center centering rotary sealer

A technology of rotary sealer and sealer, which is applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve problems such as increased labor intensity of workers, pipeline rupture, pollution accidents, etc., and achieves simple structure, large load-bearing torque, The effect of easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

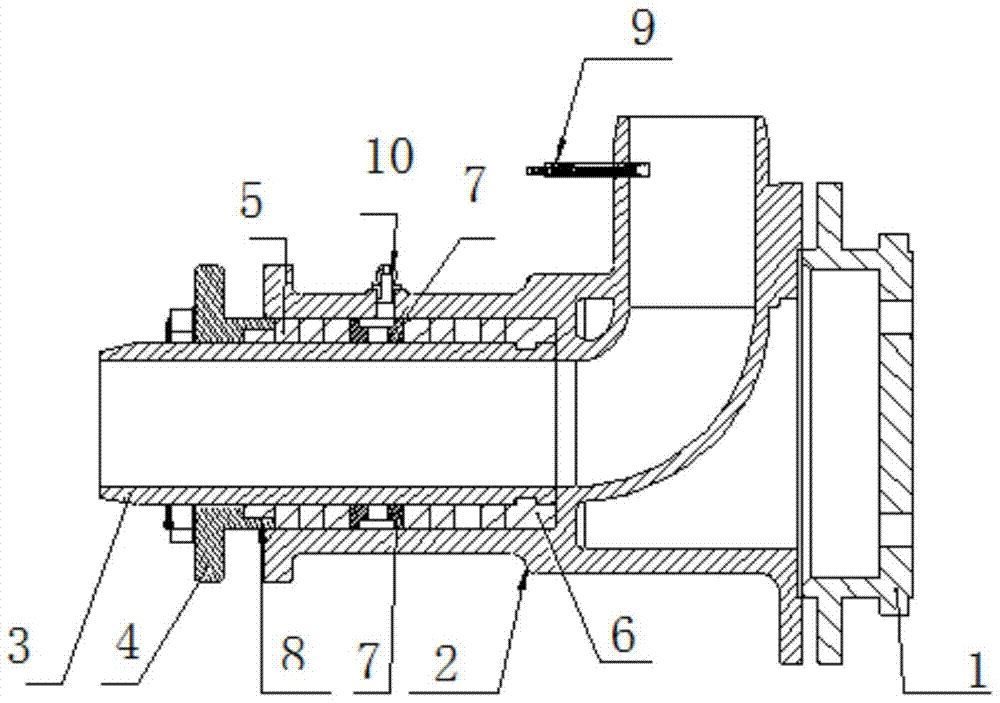

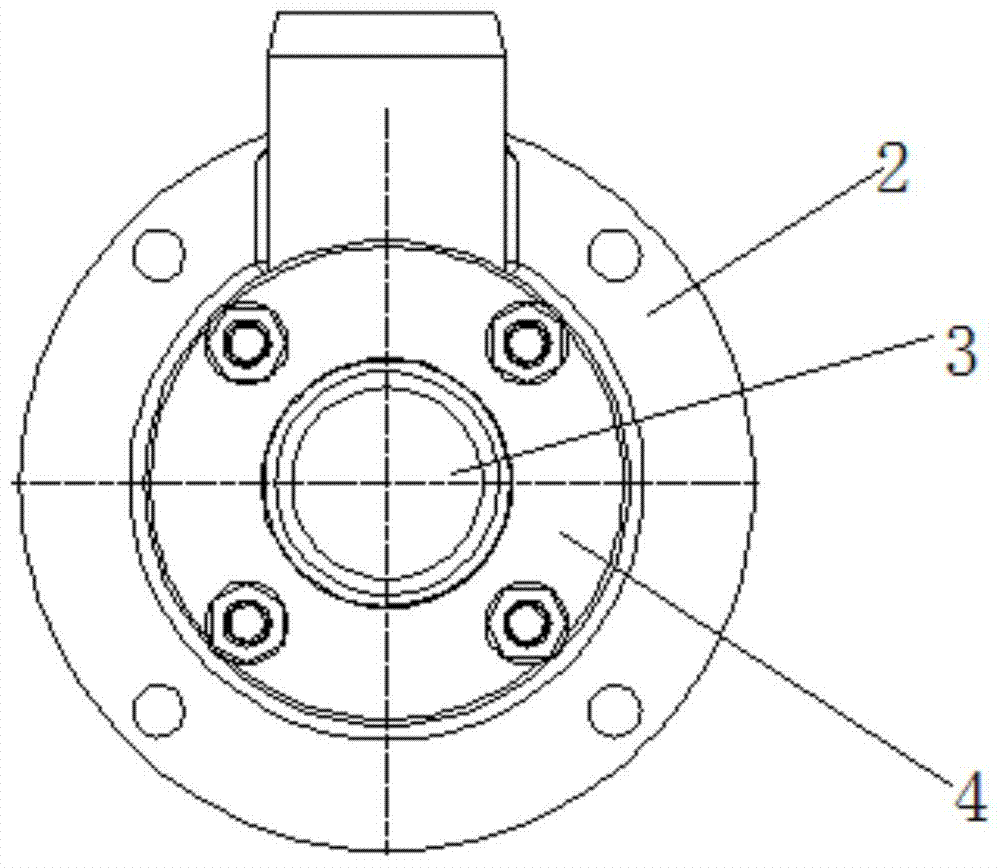

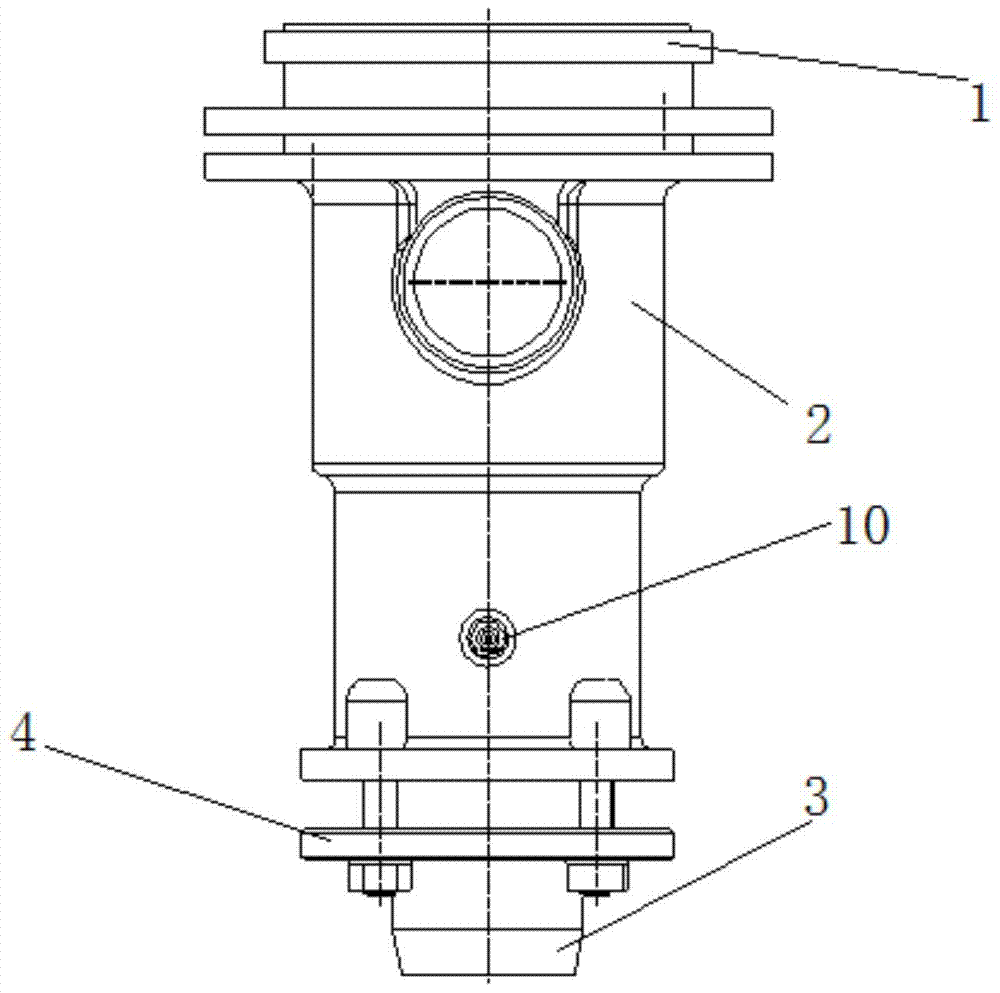

[0024] The present invention will be further described now in conjunction with accompanying drawing.

[0025] refer to Figure 1-Figure 4 , the flange connection centering rotary sealer of the present invention comprises: sealer baffle plate 1, sealer housing 2, core sleeve 3, gland 4, packing 5, positioning sleeve 6, orifice ring 7 and oil cup 10; Wherein, the sealer baffle 1 is in the shape of a flange, which is fixedly connected with the sealer housing 2; the sealer housing 2 includes a hollow pipe part and an elbow part, and the sealer housing 2 The positioning sleeve 6 is placed in the hollow tube part of the sealer housing 2, and the core sleeve 3 is positioned and installed in the hollow tube part of the sealer housing 2 through the positioning sleeve 6, and can be connected with the sealer housing The hollow tube part of the body 2 rotates relatively; the packing 5 is installed between the core sleeve 3 and the hollow tube part of the sealer housing 2, and the gland 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com