Pressure reducing pry boiler capable of retaining heat

A decompression skid, boiler technology, used in thermal storage heaters, fluid heaters, lighting and heating equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

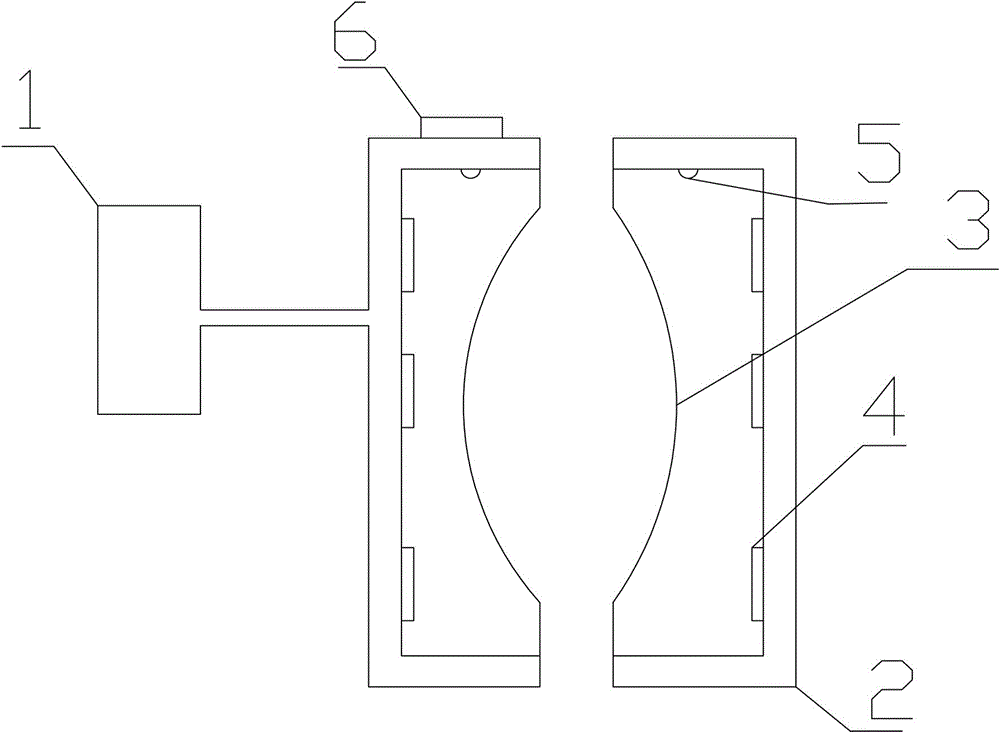

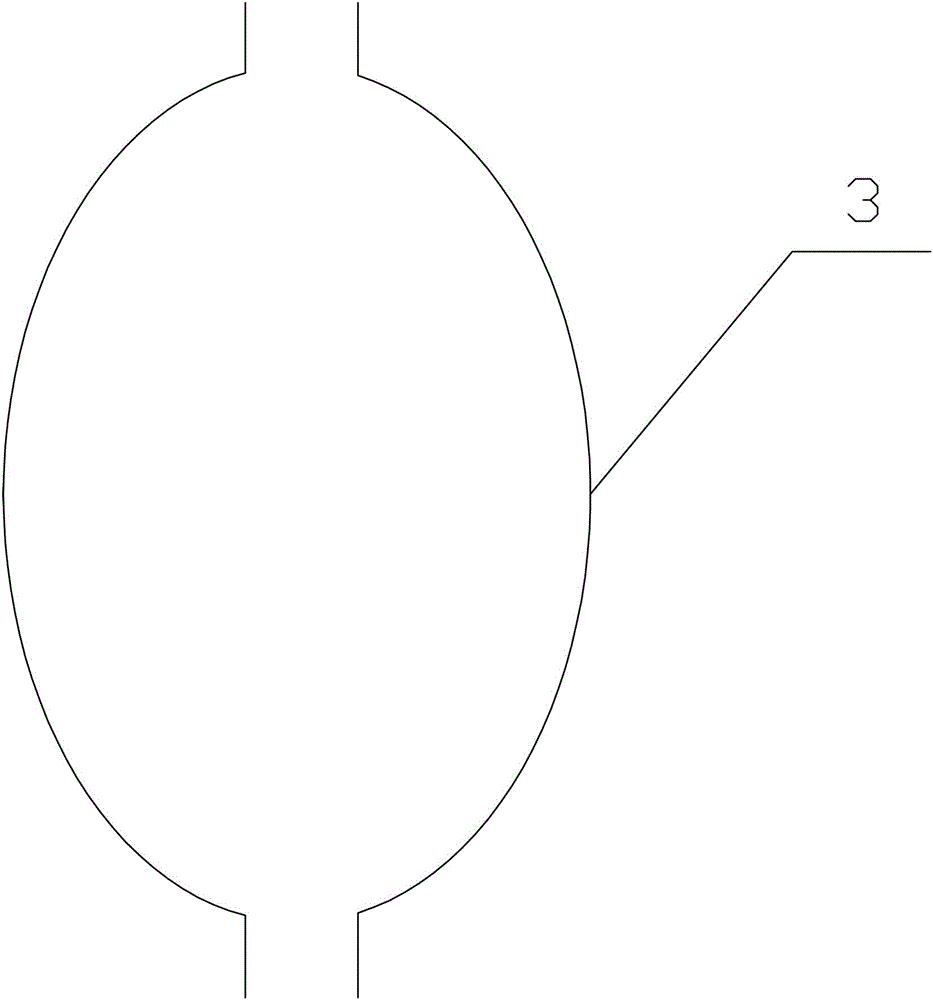

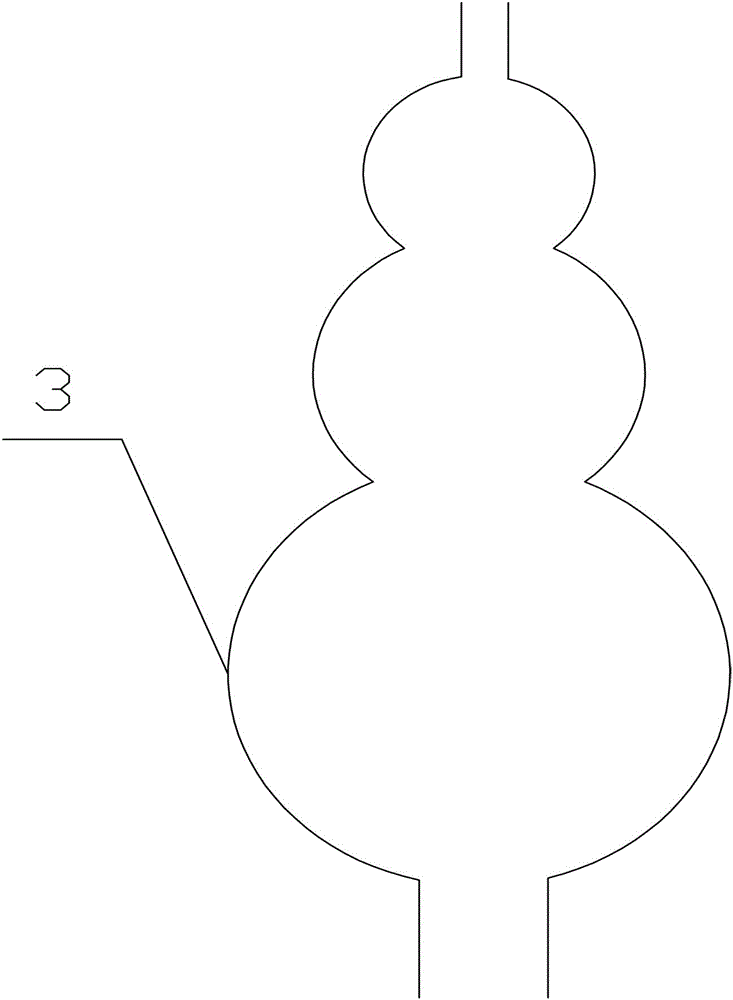

[0018] Such as figure 1 , 2 , 4, a heat-preserving decompression skid boiler includes a hot water heating device 1, a furnace body 2, a decompression chamber 3, a heating plate 4, a temperature measuring device 5, and a controller 6; the furnace body 2 is a double layer The furnace wall, the hot water heating device 1 communicates with the inner interlayer space of the double-layer furnace wall, and the heating sheet 4 is arranged on the inner wall of the body of furnace 2, and the heating sheet 4 includes an oval body 7 made of copper sheet, and is arranged on The heating electric wire 8 in the oval body 7, the heating electric wire 8 is spiral shape, and the heating electric wire 8 is connected with the power supply by the controller 6, and the controller 6 can connect or cut off the power supply of the heating plate 4; the decompression chamber 3 is provided with In the furnace body 2, there is a circular cavity in the middle of the decompression chamber 3, the furnace bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com