Heating device and heating method of oxygen generating expander

An expander, carbon dioxide technology, used in refrigeration and liquefaction, lighting and heating equipment, liquefaction and other directions, can solve the problems of reduced nitrogen production, reduced operating efficiency, and high cost, and achieve the effect of operating costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0025] The purpose of the present invention is to provide a heating device and a heating and operation method for an oxygen generator expander, which can realize low-cost, on-demand, and timely heating of the expander without being affected by the shutdown of the oxygen generator or the nitrogen pipe. Net system balance.

[0026] According to one aspect of the present invention, a heating device for an oxygen generating expander is provided. Including: heating gas pipeline, analysis control module.

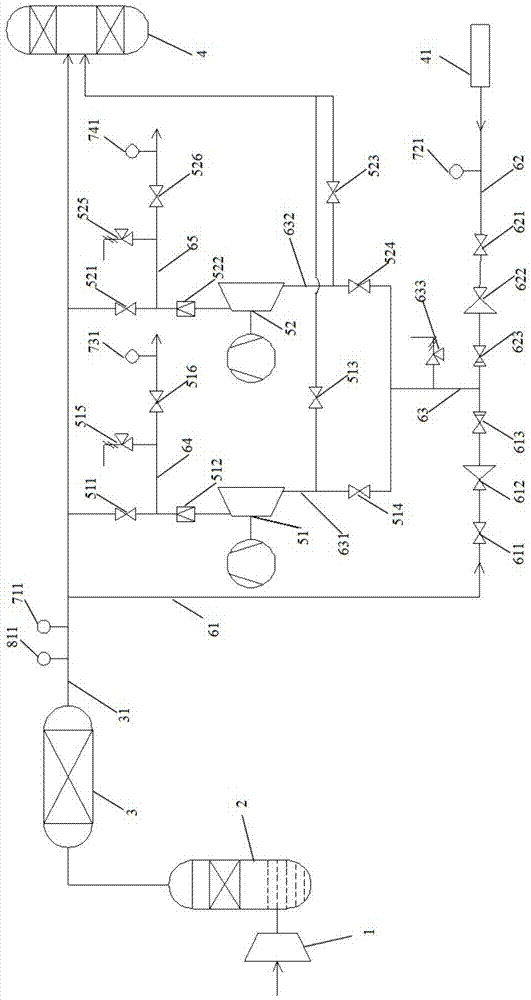

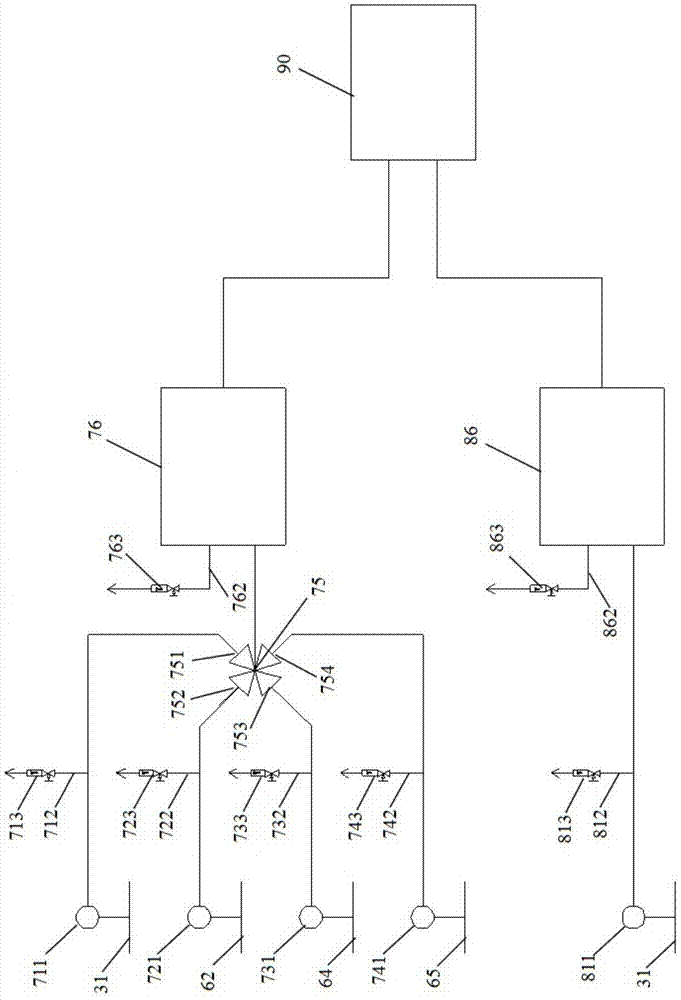

[0027] see figure 1 , the heating device of the oxygen generating expander of the present invention includes a heating gas pipeline system and an analysis control module. Wherein, the heating gas pipeline system includes an air compressor 1 , a precooling system 2 , a molecular sieve system 3 , an air separation system 4 , an i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com