Energy conservation and emission reduction method beneficial to carbon neutralization flue gas waste heat recovery and reheating technology

A technology for energy saving, emission reduction, and flue gas waste heat, which is applied in the field of flue gas treatment, and can solve problems such as heat waste, flue gas heat cannot be reused more effectively, and heat cannot be collected.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

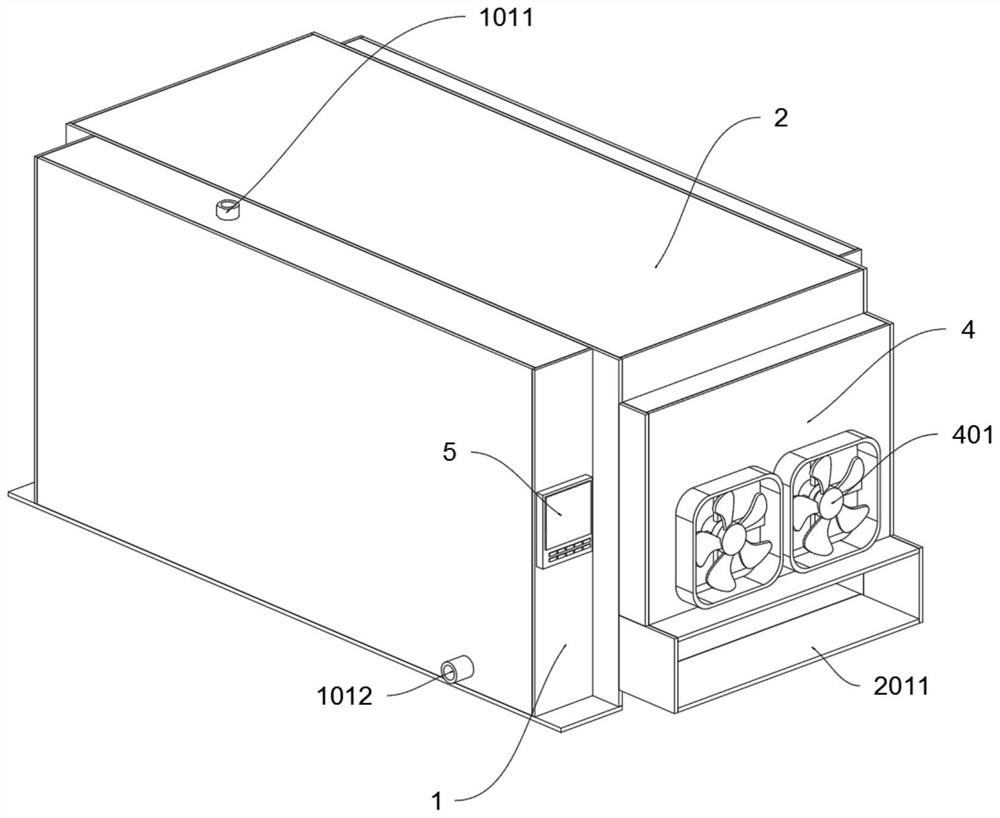

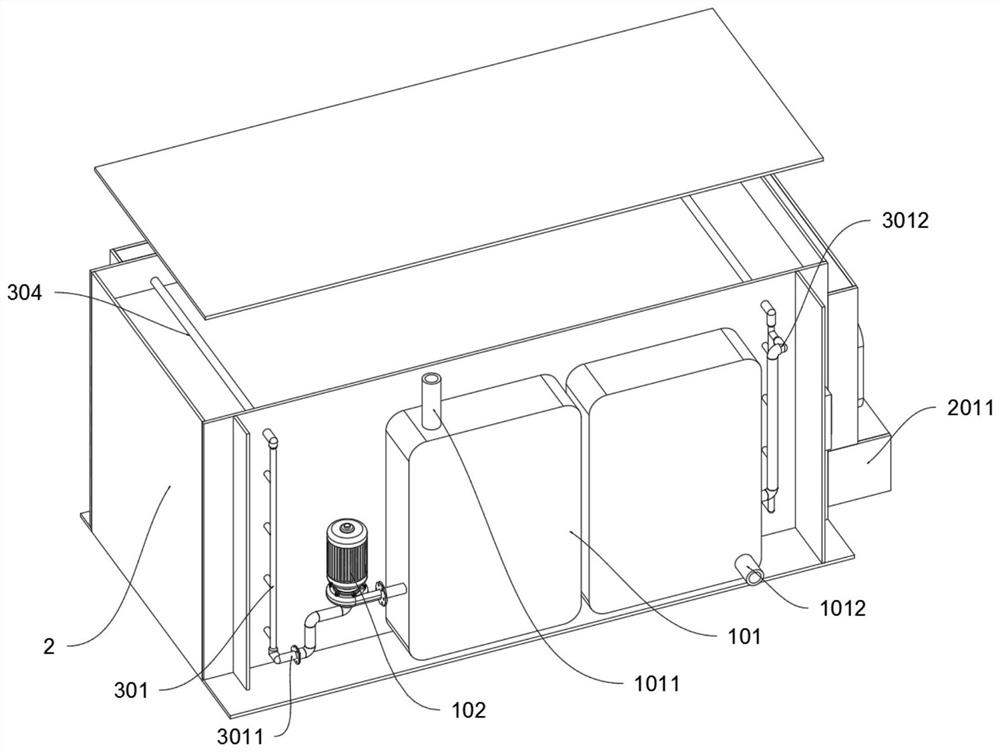

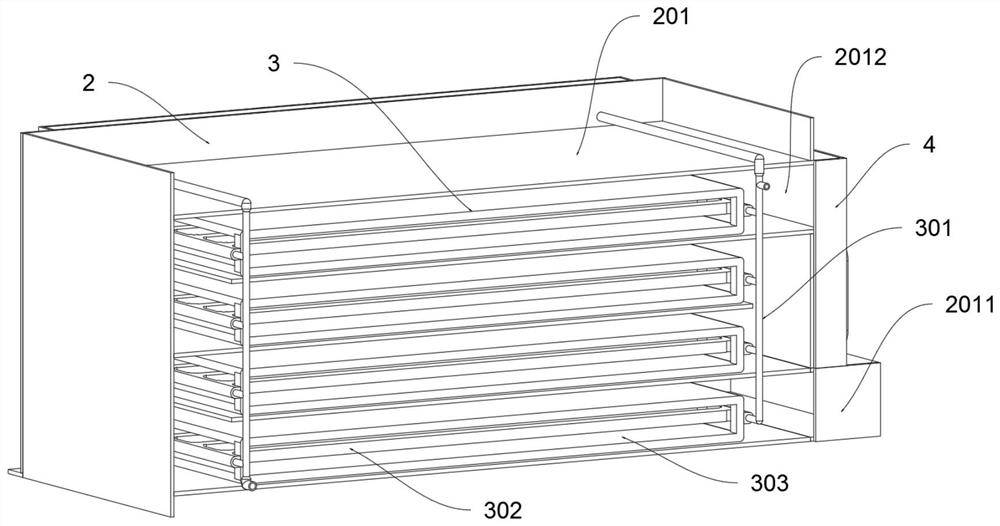

[0031] as attached figure 1 to attach Figure 7 Shown:

[0032] The present invention provides an energy-saving and emission-reduction method that is beneficial to carbon-neutral flue gas waste heat recovery and reheating technology. The energy-saving and emission-reduction method uses energy-saving and emission-reduction equipment to realize waste heat recovery and reheating of flue gas. Row equipment includes:

[0033] The waste heat exchange box 2; the waste gas discharge cover 4 is fixedly connected to the outside of the right side wall of the waste heat exchange box 2; the control instrument 5 is fixedly connected to the right outer wall of the circulation control box 1, and the control instrument 5 is electrically connected and controls the circulating water pump 102.

[0034] as attached figure 2 As shown, the circulation control box 1 is fixedly connected in front of the front wall of the waste heat exchange box 2; the circulation control box 1 includes a temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com