Air-cooled type refrigerator with heat pipe type heat storage and frost removal mechanism

An air-cooled, heat-storage technology, applied in defrosting, household appliances, household refrigeration devices, etc., can solve the problems of increased energy consumption of refrigerators, excessive temperature rise, shortening the time of food preservation in refrigerators, etc. Consumption and avoid the effect of temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

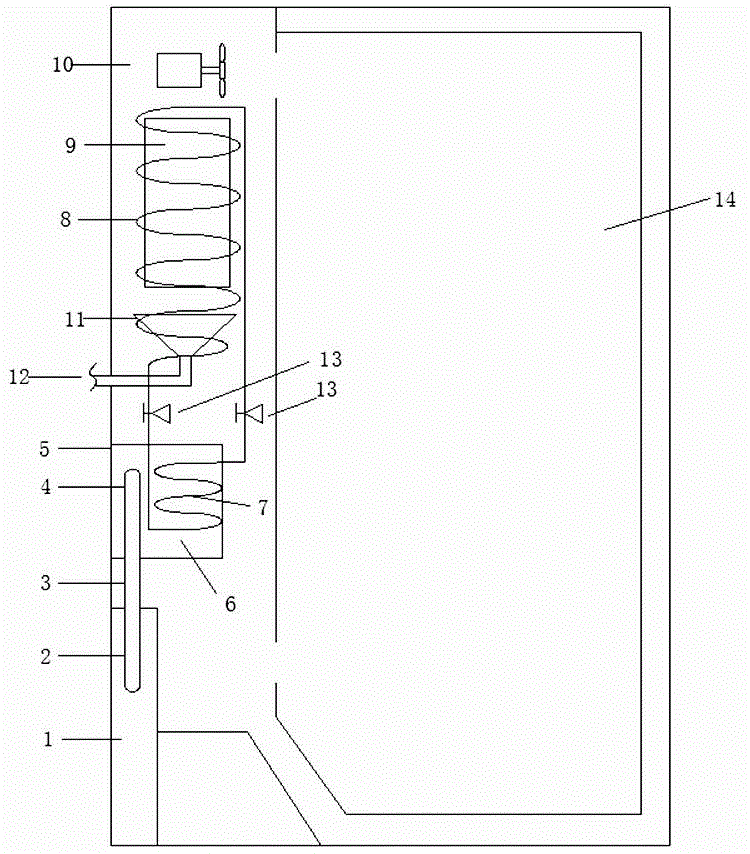

[0023] see figure 1 , the air-cooled refrigerator with a heat pipe type heat storage and defrosting mechanism includes a box body 14, a condenser 1, an evaporator 9, a fan 10, a water tray 11, a drain pipe 12, seven gravity heat pipes and an annular heat pipe;

[0024] A heat storage chamber 5 is installed on the box body 14 between the condenser 1 and the evaporator 9, and the heat storage chamber 5 is filled with a phase change heat storage material 6, and the phase change temperature of the phase change heat storage material 6 is 10-50°C.

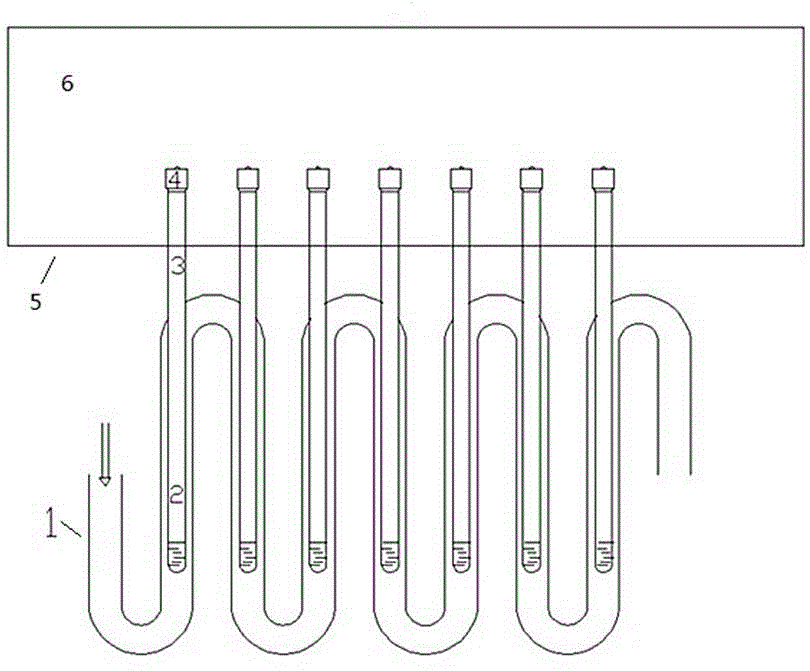

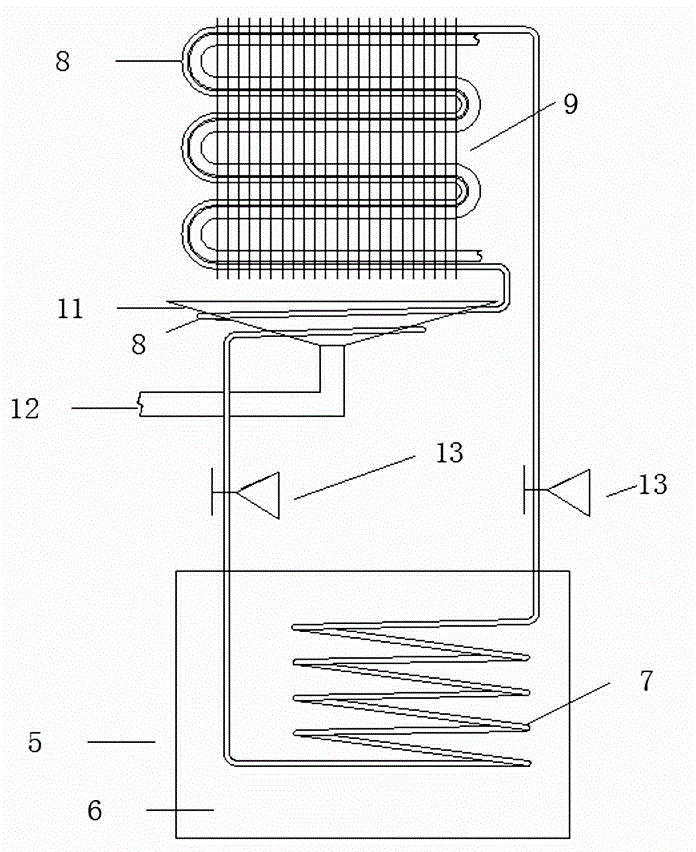

[0025] see figure 2 , the gravity heat pipe evaporation section 2 of the seven gravity heat pipes is inserted in the condensation coil of the condenser 1, and the gravity heat pipe condensation section 4 extends into the heat storage chamber 5 and is wrapped by a phase change heat storage material 6. see image 3 , two control valves 13 are installed on the annular heat pipe; the evaporating section 7 of the annular heat pipe is locat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com