Automatic sand grain detection mechanical device

A technology of mechanical device and detection mechanism, applied in the direction of analyzing materials, instruments, etc., can solve the problems of incompatibility, high labor intensity and high scrap rate, and achieve the effect of avoiding scrap products, low labor intensity of personnel, and reducing scrap rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

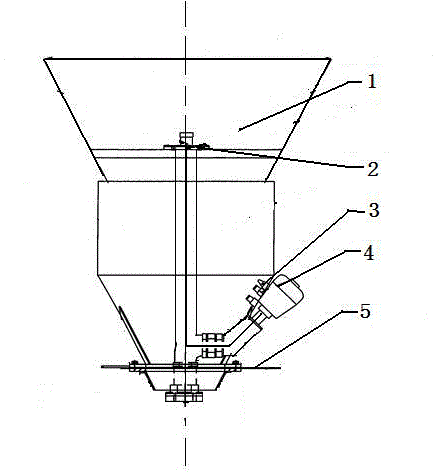

[0012] This embodiment provides an automatic sand detection mechanical device, which is characterized in that: the automatic sand detection mechanical device includes a sand hopper (1), an automatic control valve (2), an induction head (3), and a controller (4) , Baffle (5);

[0013] Wherein: the sand hopper (1) is provided with a detection mechanism, and the material level detection mechanism includes several induction heads (3), which are arranged on the inner wall of the sand hopper from top to bottom. (3) Connect with a controller (4), an automatic control valve (2) is arranged on the sand hopper (1), and the automatic control valve (2) is connected with the controller (4).

[0014] The said induction head (3) can be set to 3 to 6, or even more.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com