Particle granularity measuring device and method based on near-field scattering

A measuring device and near-field technology, which is applied in the direction of measuring device, particle size analysis, particle and sedimentation analysis, etc., can solve the problems of low stability, measurement of particle size easily affected by stray light, complex device, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments. It should be understood that these embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention. After reading the present invention, those skilled in the art all fall into the appended claims of the present application to the amendments of various equivalent forms of the present invention limited range.

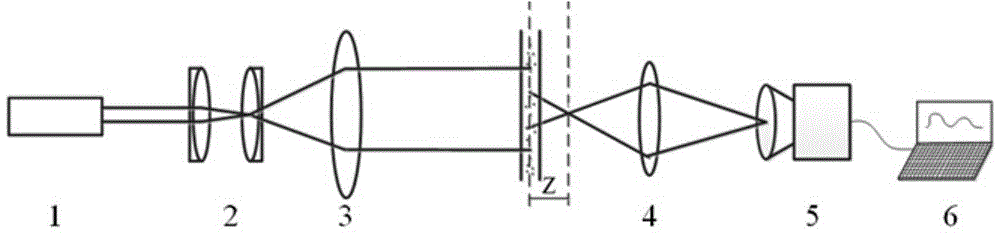

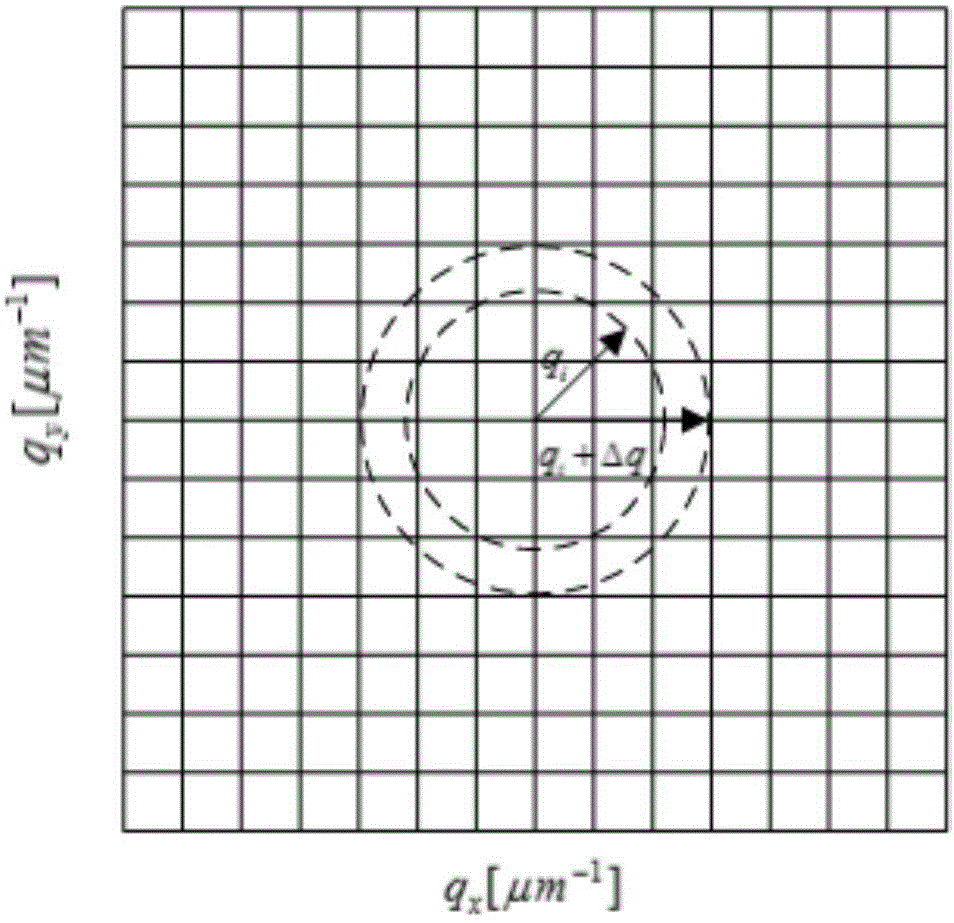

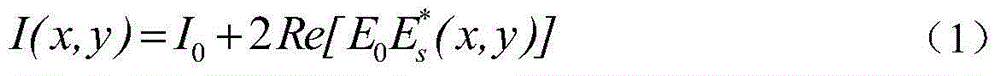

[0036] The working principle of the present invention: the laser emits a coherent beam, and through the spatial filter, most of the stray light generated by the laser is filtered out, and then the laser is collimated by the collimating lens, and the collimated beam irradiates the solution to be measured, due to the particles Scattering occurs due to existence, and then the focal length of the lens behind the measurement area is adjusted, so that the speckle image formed by the su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com