Computer image based automatic identification method of timber knot flaws

An automatic identification and computer technology, applied in the field of wood processing, can solve the problems of difficult to meet the high-speed and precise requirements of wood processing automation, subjective consciousness interference, automatic identification method of flawed computer images, etc., to meet the requirements of speed and quality, speed Fast, easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The invention proposes a computer image automatic recognition method for wood knot defects. Describe in detail below in conjunction with accompanying drawing:

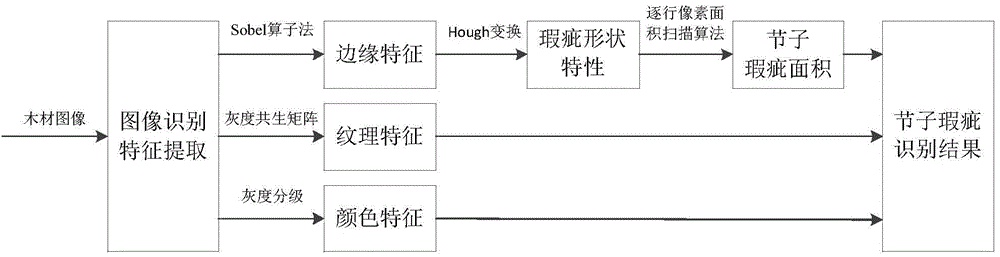

[0021] The computer image automatic recognition principle block diagram of the wood knot defect of the present invention is as follows figure 1 As shown, after the feature extraction of the wood image, the edge features, texture features and color features of the knot defects are obtained, the shape characteristics of the defects are judged by Hough transform, the candidate area is determined, and the defect area is calculated according to the progressive pixel area scanning algorithm, and finally The image recognition results of wood knot defects are obtained from the features of knot defect area, texture and color.

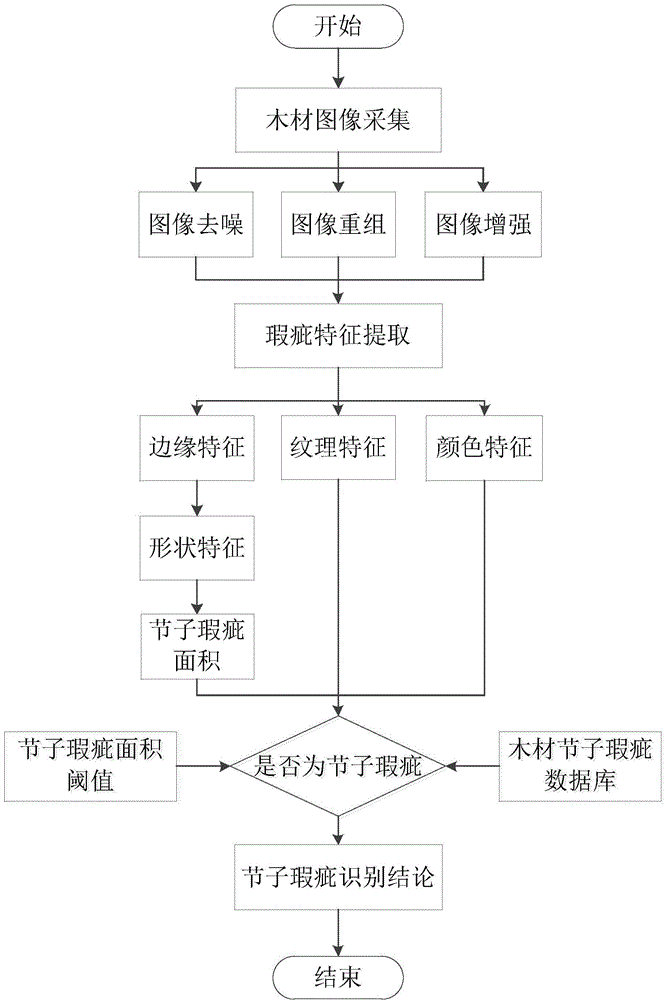

[0022] like figure 2 As shown, the process of the computer image automatic recognition method for wood knot defects is as follows:

[0023] The first step is to use a digital high-definition C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com