Control system, valve base control equipment and submodule integration method

A valve-based control equipment and control system technology, applied in the direction of DC network circuit devices, electrical components, circuit devices, etc., can solve the problem of not meeting the control and protection requirements of modular flexible DC transmission valves, not having real-time control capabilities of different sub-modules, etc. problem, to achieve the effect of improving data throughput, real-time performance and reliability of data transmission, increasing computing speed, and reducing system control delay

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

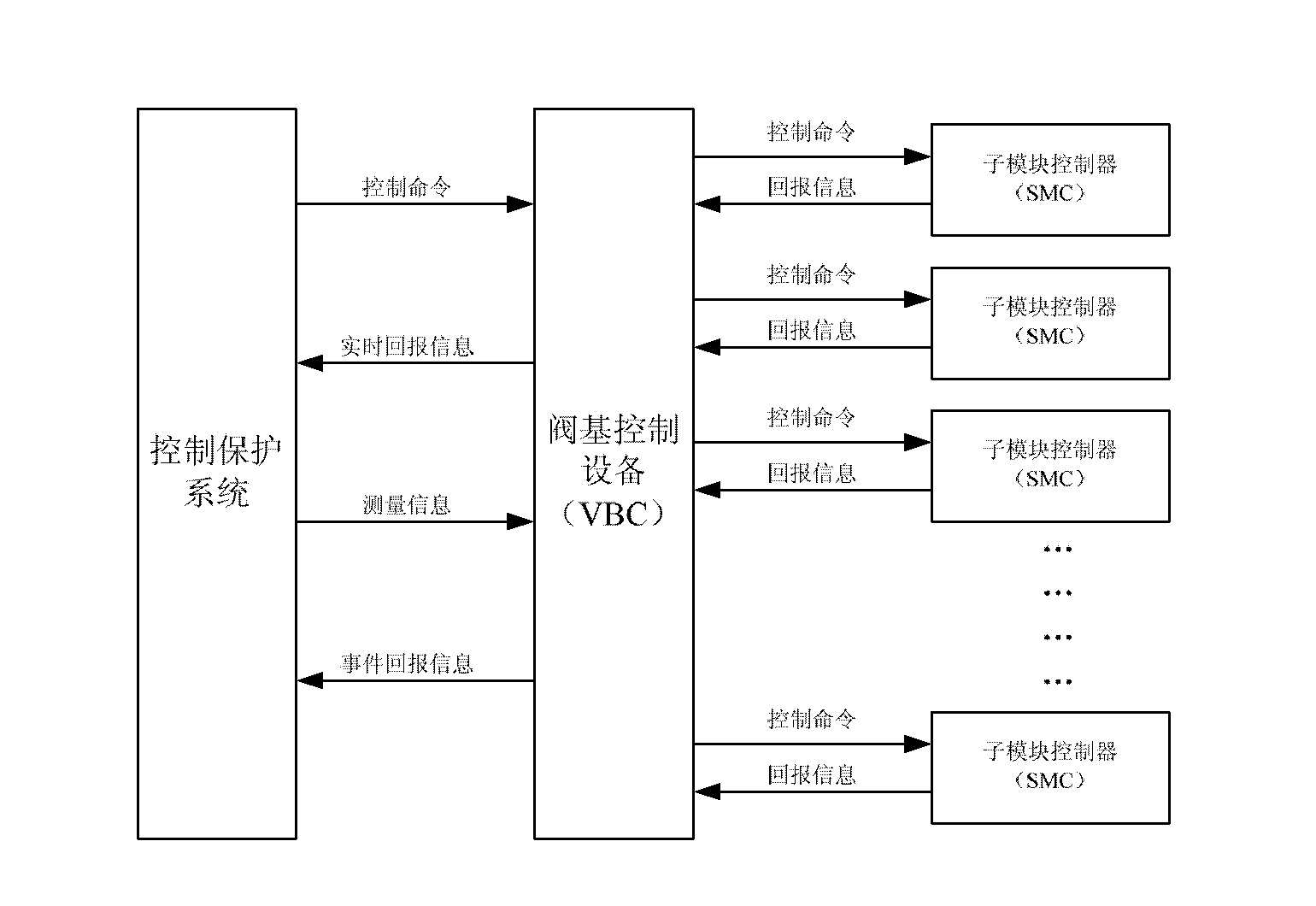

[0023] The valve-based control equipment is the interface equipment of the modular multi-level flexible DC transmission control and protection system and the converter valve, and is mainly used to complete the control, monitoring and protection of the valve. Whenever the control and protection system issues a valve control command, the valve base control device switches or bypasses the converter valve according to the command.

[0024] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

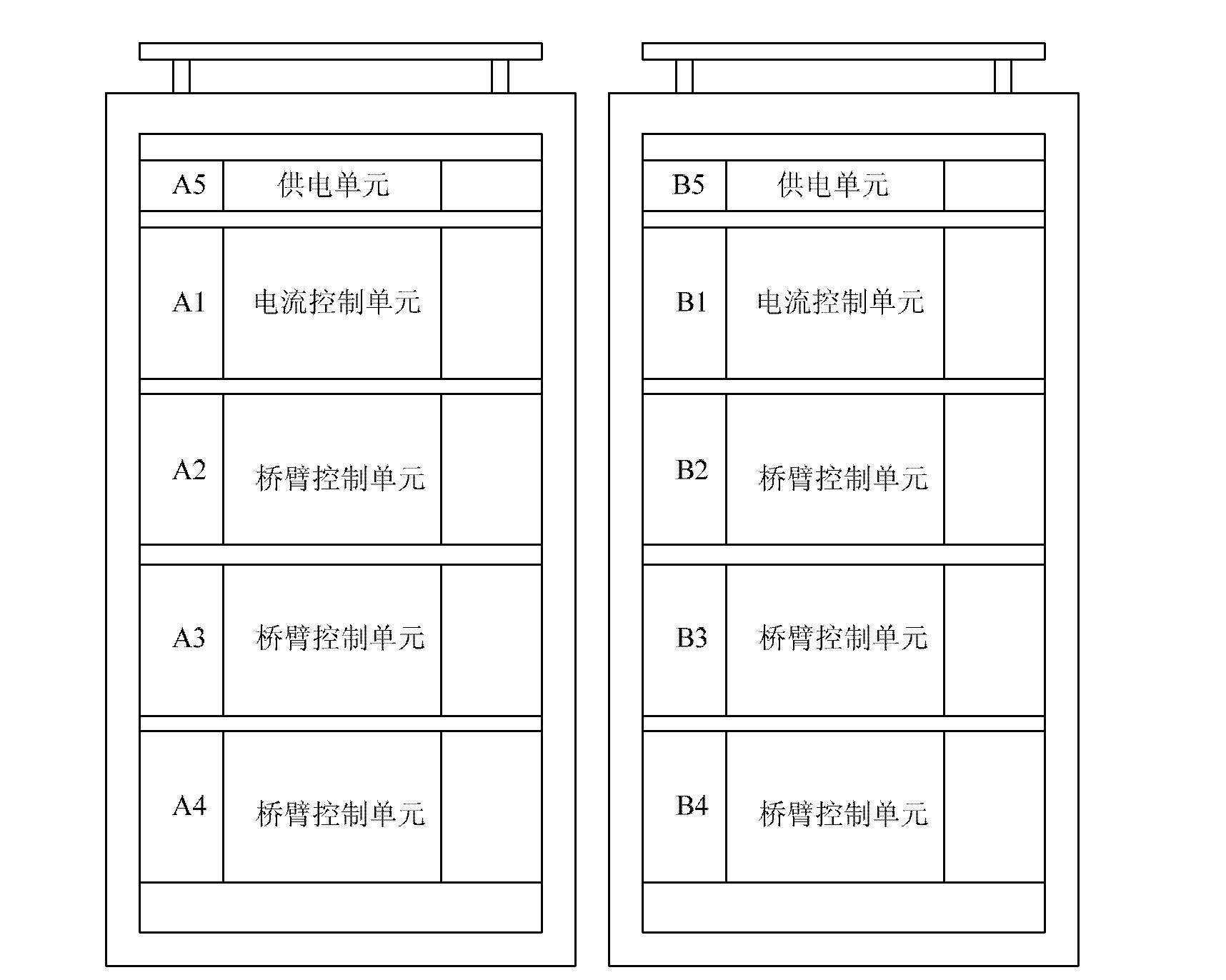

[0025] figure 1 Among them, the valve base control equipment adopts the hardware structure of the current control unit and the bridge arm control unit, and is composed of two panel cabinets. A1 and B1 are two independent current control units, and A2 to A4, B2 to B4 are 6 independent The bridge arm control unit, A5 and B5 are two independent power supply units, and the two current control units ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com