Control method for electro-magnetic synchronous motor

A technology of synchronous motor and control method, applied in motor generator control, electronic commutation motor control, AC motor control and other directions, can solve the problems of reference current error, power factor drop, no unified solution, etc., to achieve power factor control Accurate, restrained inductance parameter variation, simple and clear control structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

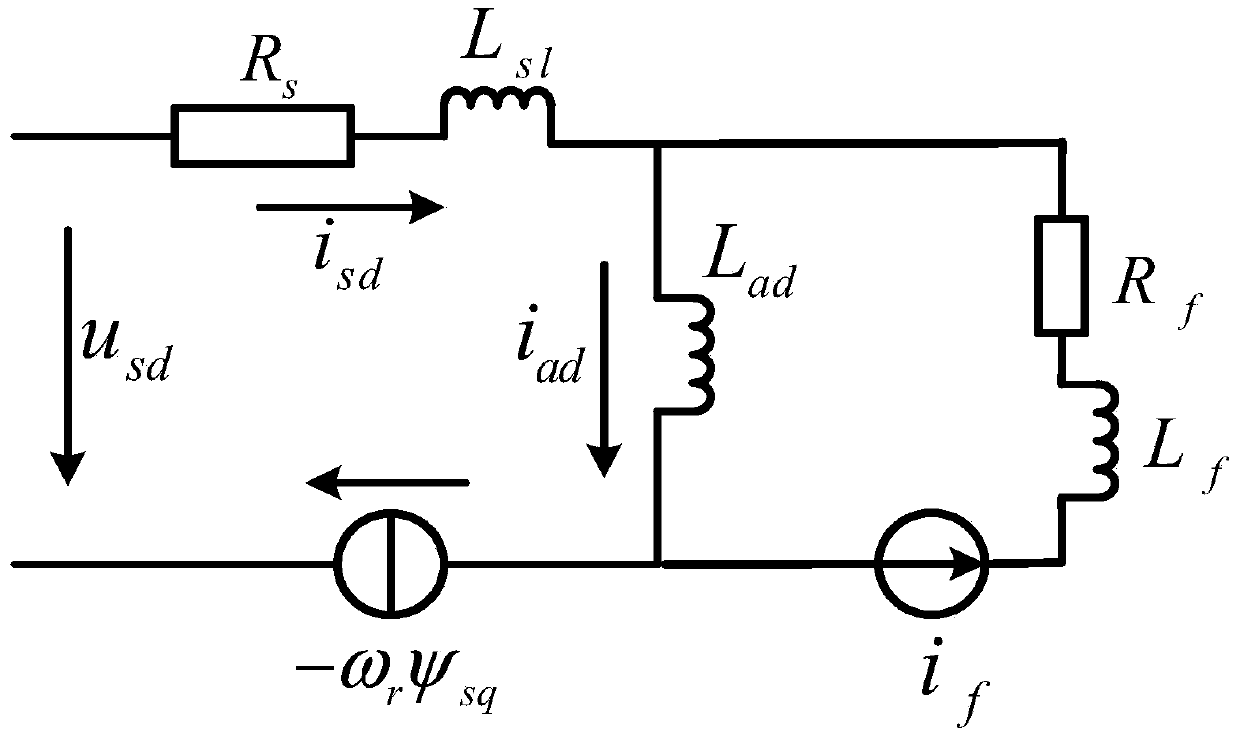

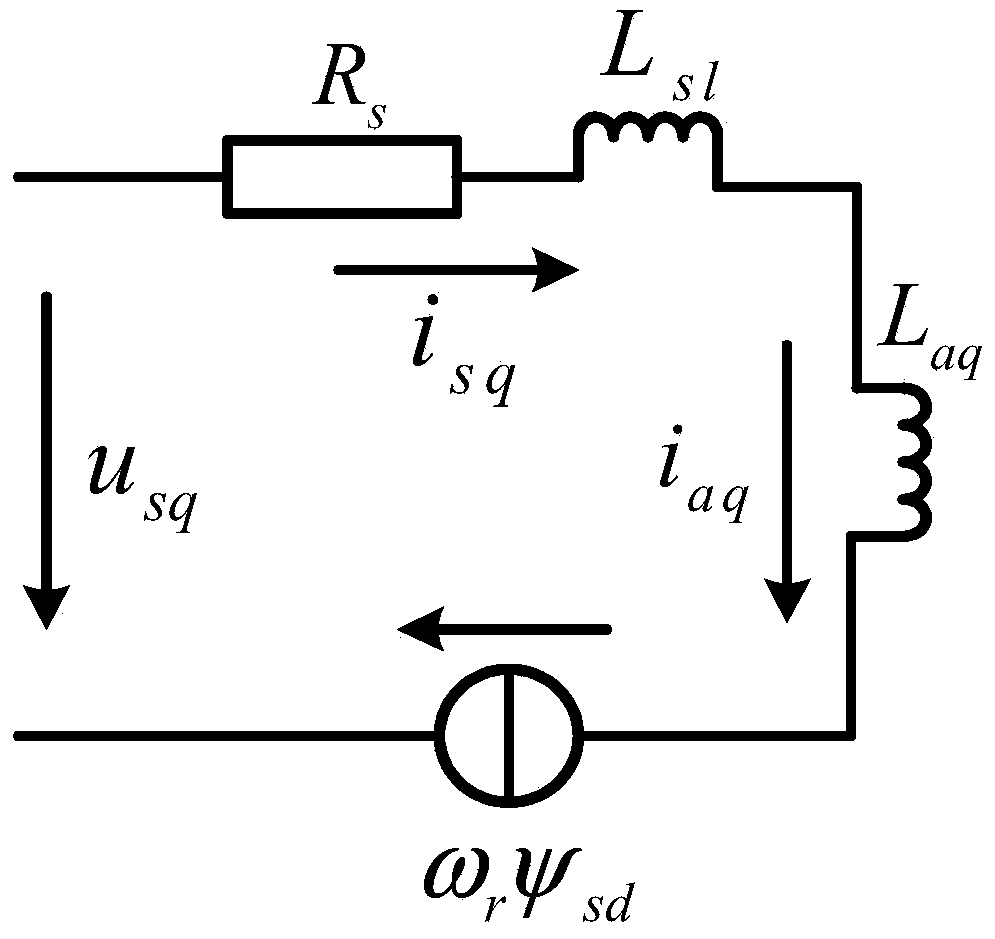

[0043] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

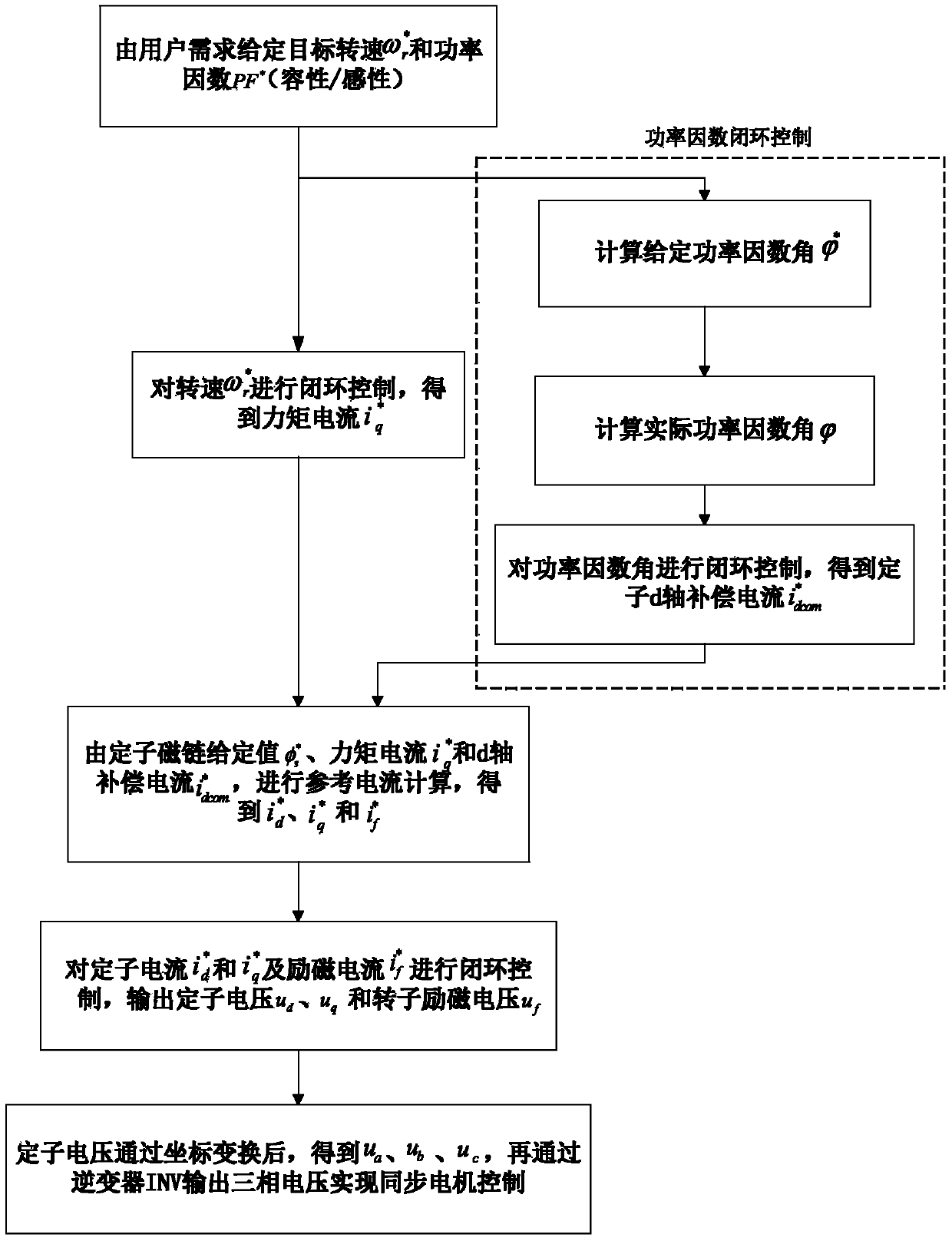

[0044] Such as image 3 and Figure 4 Shown, the control method of electric excitation synchronous motor of the present invention, flow process is:

[0045] (1) The target speed is given by the user's demand and power factor PF * (capacitive / inductive); where, is the given speed, ω r is the rotational speed of the synchronous motor SM measured by the sensor; PF * (capacitive / inductive) is given for the power factor required by the user.

[0046] (2) Through the PI regulator to the target speed Carry out closed-loop control to obtain the stator torque current (that is, the q-axis current given value ); Calculate the given power factor angle Actual Power Factor Angle And perform closed-loop control on the power factor angle to obtain the stator d-axis compensation current

[0047] Power factor is generally divided i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com