An electromagnetic heating coil and an electromagnetic cooker that are reversely wound one by one

A reverse winding, electromagnetic technology, applied in the direction of electric heating fuel, induction heating, lighting and heating equipment, etc., to achieve the effect of simple processing process, improved utilization rate, and simple winding method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Further illustrate the technical scheme of this patent below in conjunction with accompanying drawing.

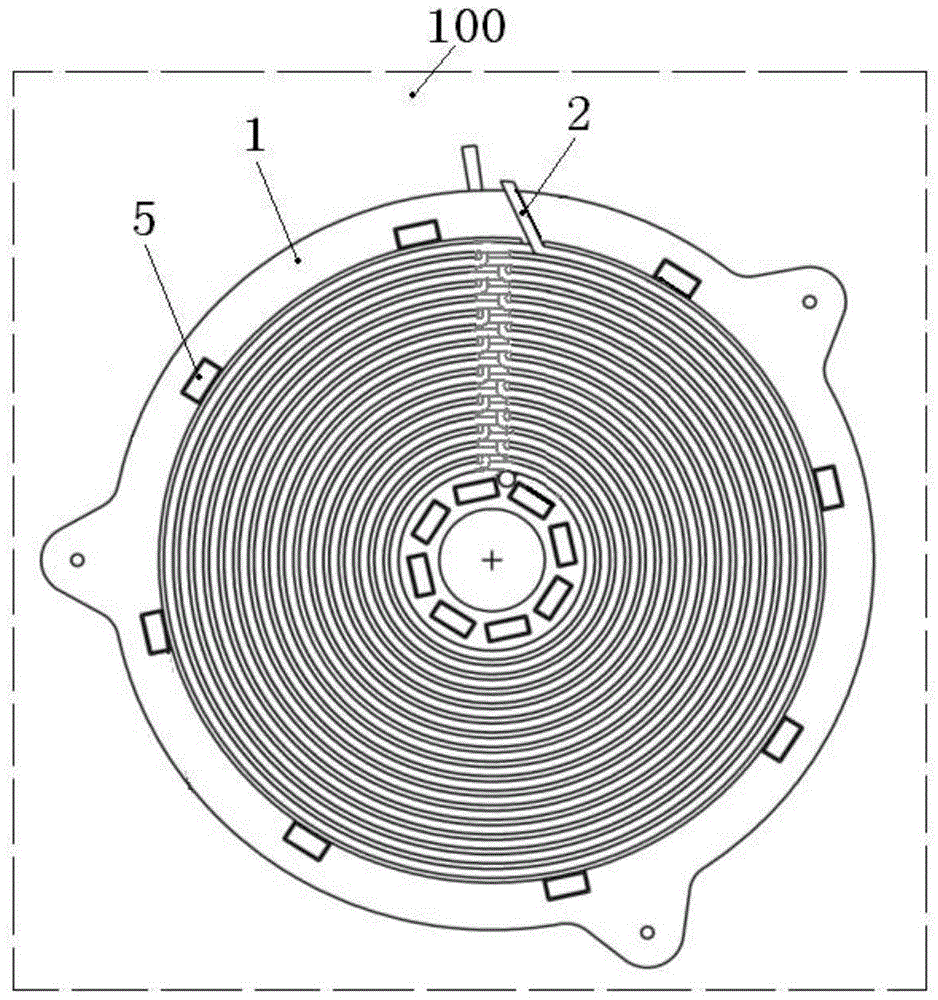

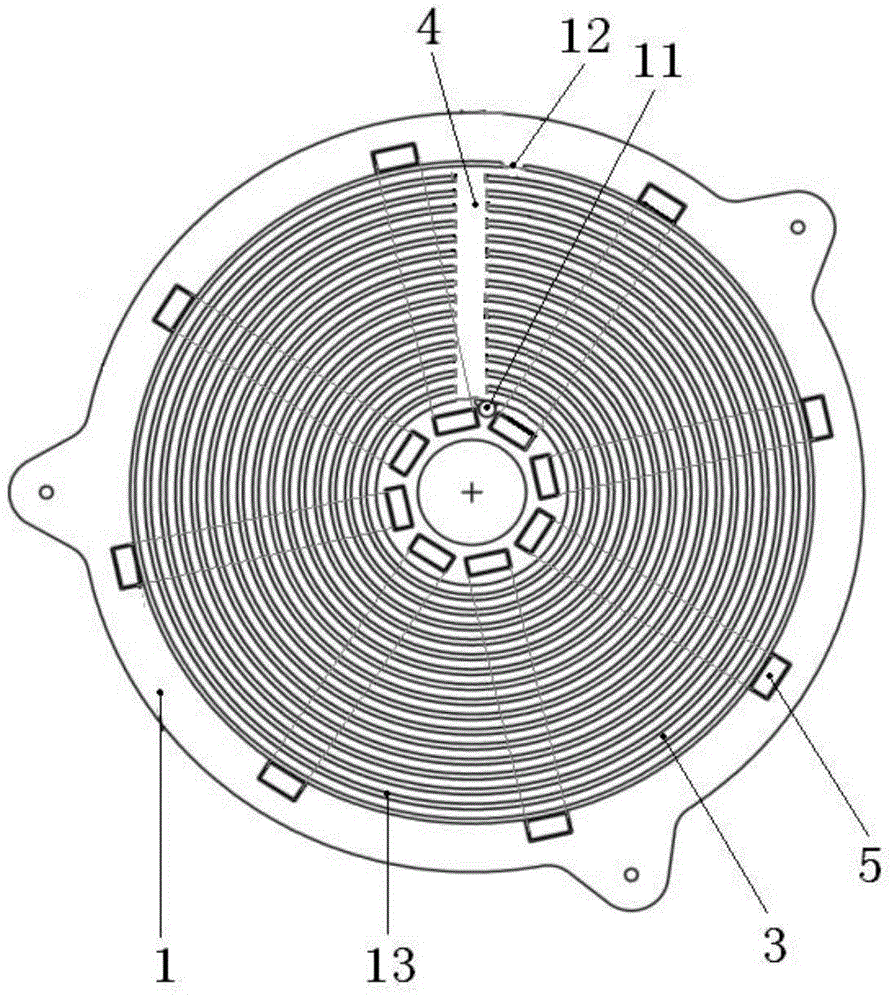

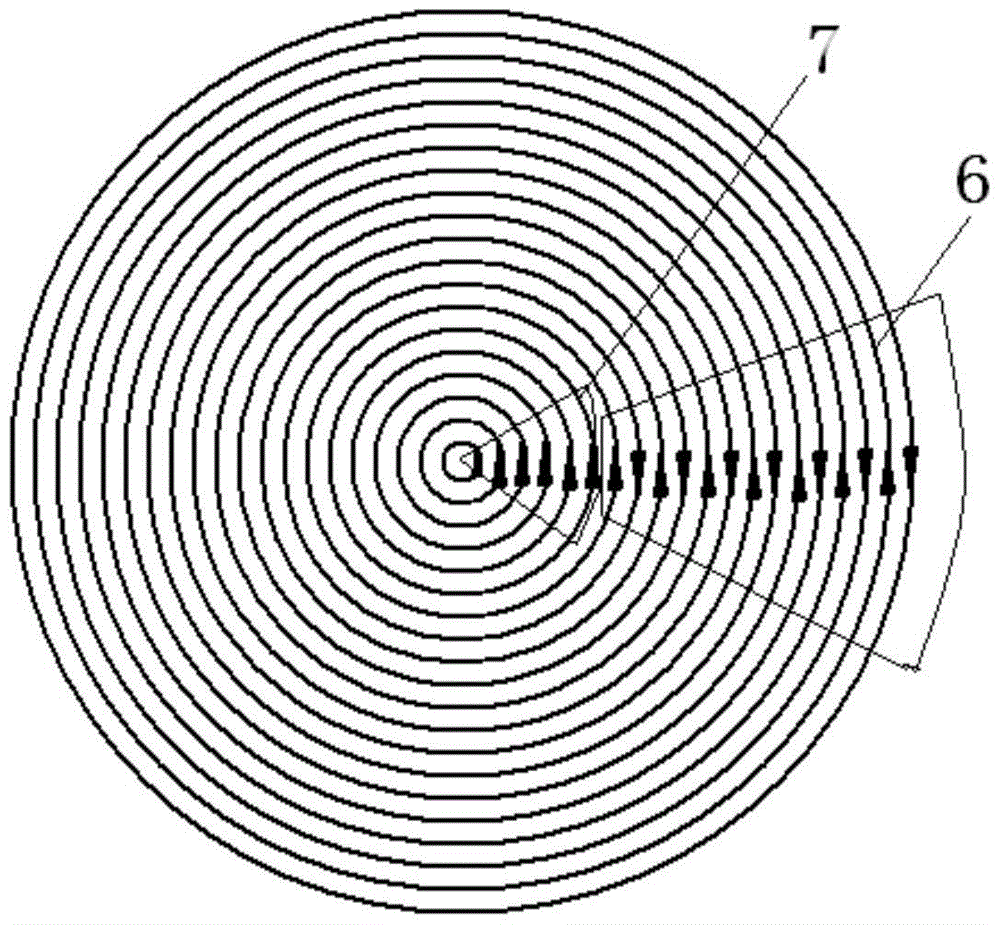

[0021] Figure 1 and figure 2 As shown, a kind of electromagnetic heating reel of a kind of induction cooker reversely wound round by turn: it includes a wire reel frame 1 and a coil winding 2, the coil winding 2 is installed on the wire reel frame 1, and the wire reel frame 1 includes several concentrically arranged The annular winding grooves 3 of equal width are separated by annular retaining ribs 13 between adjacent winding grooves 3, and all the annular retaining ribs that separate the winding grooves 3 are separated in a certain radial direction. The ribs 13 are opened with gaps of equal width, so that all the gaps are on the same straight line segment. These gaps are called reversing diameter-reducing grooves 4, and the reversing diameter-reducing grooves 4 make each winding groove 3 communicate with each other; Including wire inlet trough 11 and wire outlet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com